Method for treating high-concentration phenol-ammonia wastewater

A high-concentration, wastewater technology, applied in ammonia preparation/separation, chemical instruments and methods, water/sewage multi-stage treatment, etc. Treatment and other problems, to achieve the effect of reducing energy consumption and purification load, shortening the treatment process, and reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

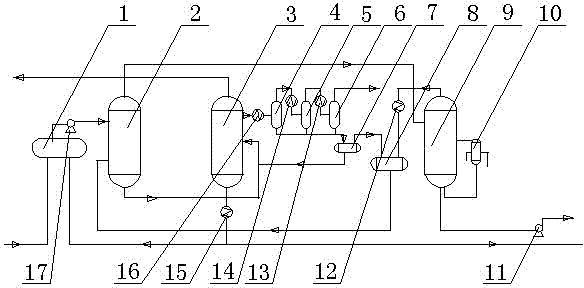

[0023] Applying the above-mentioned device for treating coal gasification wastewater containing phenol and ammonia, the total phenol content of coal gasification wastewater is 16798 mg / L, the free ammonia is 2018 mg / L, the fixed ammonia is 1864 mg / L, and the CO 2 2435 mg / L, pH value is 8.7, water temperature is 65°C, flow rate is 107 t / h, press figure 1 process shown. The phenol extraction tower 2 is a packed tower with a top temperature of 80°C, a top pressure of 0.3 MPa, a bottom temperature of 120°C, and a bottom pressure of 0.35 MPa. The deacidification and deamination tower 3 is a plate tower, the temperature at the top of the tower is 120°C, the pressure at the top of the tower is 0.32 MPa, the temperature at the bottom of the tower is 160°C, and the pressure at the bottom of the tower is 0.36 MPa. The output is 3653 kg / h. The operating pressure of the three-stage partial condenser is 0.51 MPa, and the operating temperature is 135.4°C; the operating pressure of the se...

Embodiment 2

[0025] Applying the above-mentioned device for treating coal gasification wastewater containing phenol and ammonia, the total phenol content of coal gasification wastewater is 5364 mg / L, the free ammonia is 1034 mg / L, the fixed ammonia is 1508 mg / L, and the CO 2 2352 mg / L, pH value is 7.8, water temperature is 72°C, flow rate is 94 t / h, according to figure 1process shown. The phenol extraction tower 2 is a packed tower with a top temperature of 78°C, a top pressure of 0.28 MPa, a bottom temperature of 119°C, and a bottom pressure of 0.32 MPa. The deacidification and deamination tower 3 is a plate tower, the temperature at the top of the tower is 117°C, the pressure at the top of the tower is 0.31 MPa, the temperature at the bottom of the tower is 155°C, and the pressure at the bottom of the tower is 0.34 MPa. The output is 3294 kg / h. The operating pressure of the three-stage partial condenser is 0.54 MPa, and the operating temperature is 133.7°C; the operating pressure of t...

Embodiment 3

[0027] Applying the above-mentioned device for treating coal gasification wastewater containing phenol and ammonia, the total phenol content of coal gasification wastewater is 4381 mg / L, the free ammonia is 1285 mg / L, the fixed ammonia is 1438 mg / L, and the CO 2 3452 mg / L, pH value is 7.2, water temperature is 75°C, flow rate is 116 t / h, press figure 1 process shown. The phenol extraction tower 2 is a packed tower with a top temperature of 82°C, a top pressure of 0.33 MPa, a bottom temperature of 127°C, and a bottom pressure of 0.35 MPa. The deacidification and deamination tower 3 is a plate tower, the temperature at the top of the tower is 118°C, the pressure at the top of the tower is 0.30 MPa, the temperature at the bottom of the tower is 166°C, the pressure at the bottom of the tower is 0.36 MPa, the gas output in the middle and upper part is 4176 kg / h, and the gas at the top of the tower is 4176 kg / h. The output is 2787 kg / h. The operating pressure of the three-stage p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com