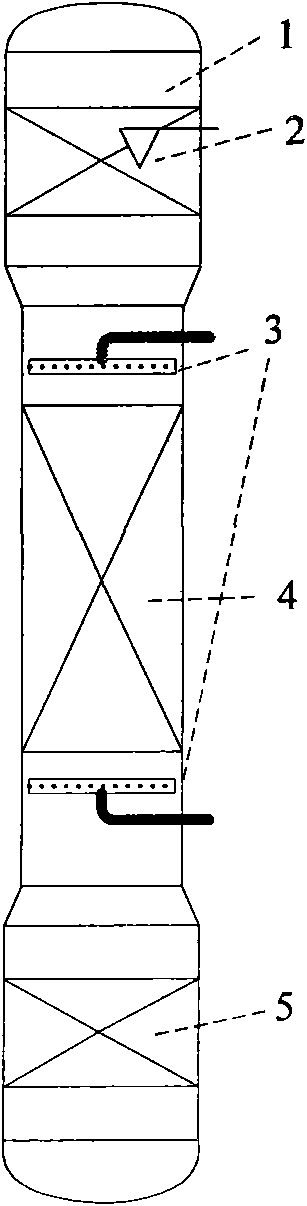

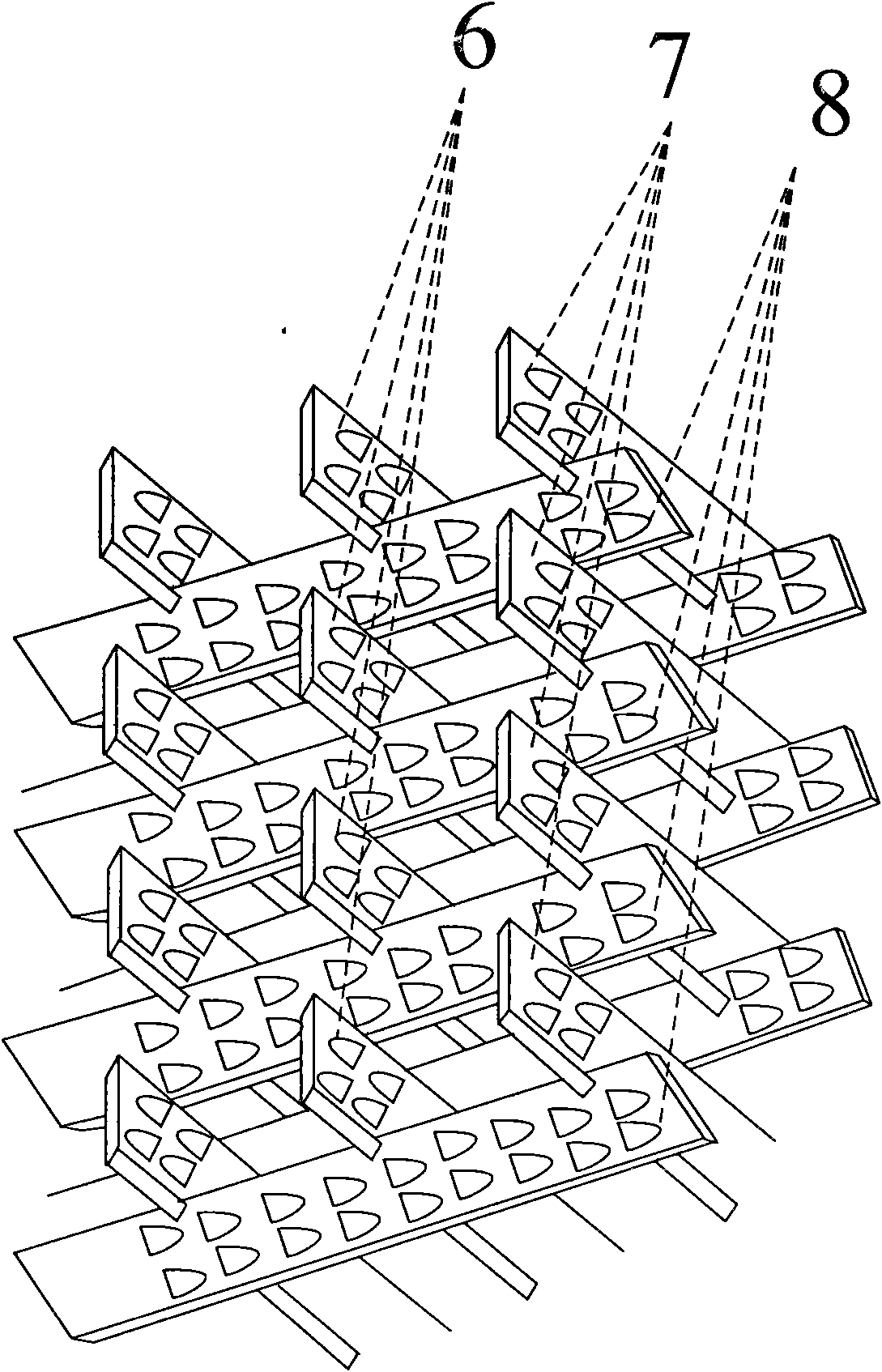

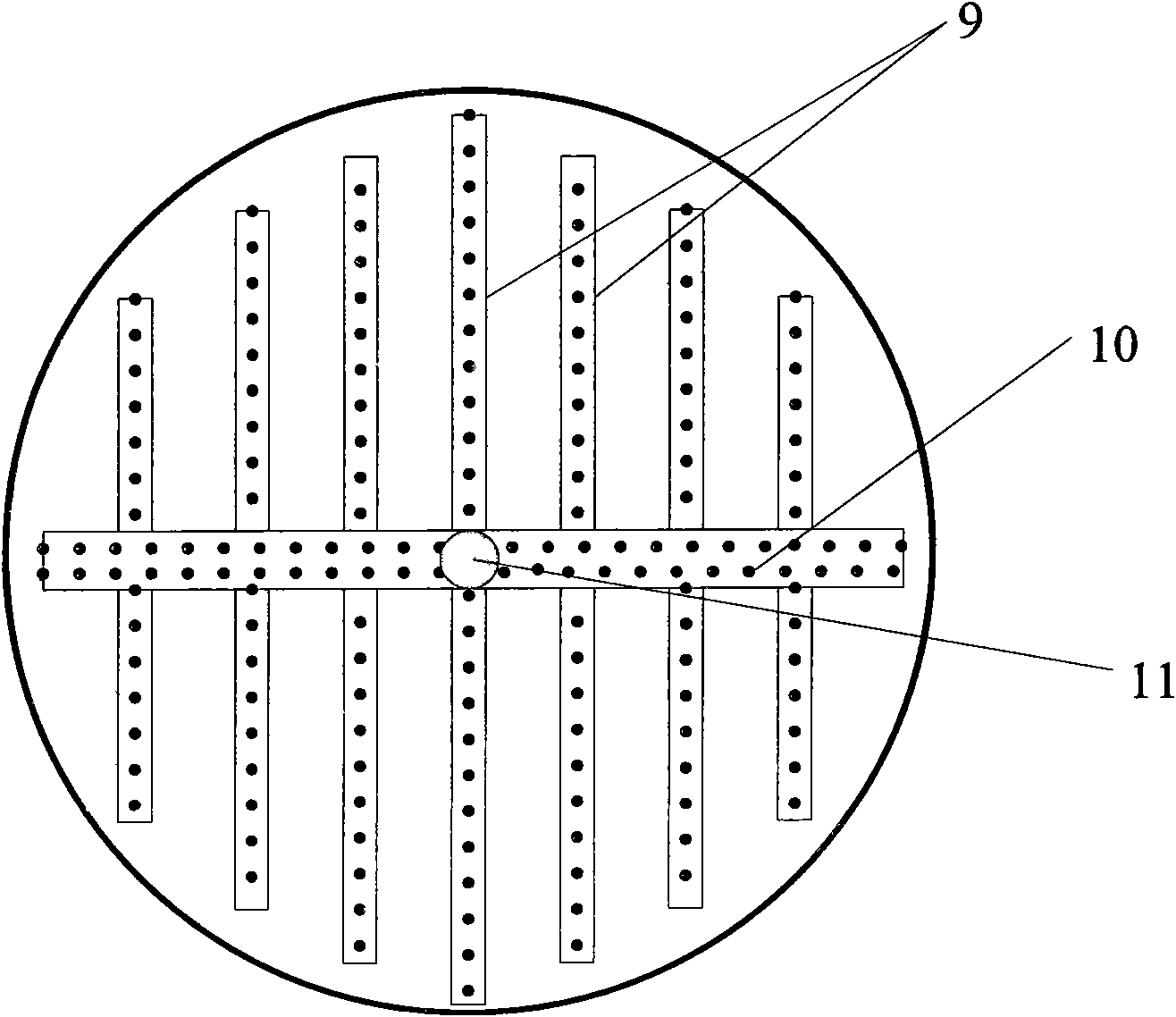

Filler extraction tower for dephenolizing coal gasification wastewater and extraction dephenolizing processing method

A technology of coal gasification wastewater and extraction tower, which is applied in the direction of extraction water/sewage treatment, etc. It can solve the problems of difficult to meet the wastewater discharge index, does not involve packing extraction tower, and exceeds the biochemical treatment load, etc., and is easy to install and maintain, and easy to install and maintain and promote decentralized effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The total phenol content of a coal gasification wastewater entering a packed extraction tower is 6010mg·L -1 , the pH value is 6, the water temperature is 50°C, and the flow rate is 100 tons / hour.

[0039] The extraction tower is a packed tower, the height of the packing layer is 17.5m, the extraction agent is methyl isobutyl ketone, and the ratio of solvent to sewage is 1:6. The theoretical number of stages of the solvent recovery tower is 20, the pressure at the top of the tower is 0.11MPa, the temperature is 110°C, the pressure at the bottom of the tower is 0.12MPa, the temperature is 215°C, and the reflux ratio is 0.5. During operation, the phase interface in the upper amplification section of the extraction tower is easy to control, and the total phenol content in the treated wastewater is 280mg·L -1 , the phenol content in the recovery extraction solvent is about 80mg / l -1 , the content of extractant in crude phenol is about 800mg / l -1 . The removal rate of ph...

Embodiment 2

[0041] The total phenol content of the coal gasification sewage entering the packed extraction tower is 5680mg·L -1 , the pH value is 5, the water temperature is 50°C, and the flow rate is 60 tons / hour.

[0042] The extraction tower is a packed tower, the height of the packing layer is 17.5m, the extraction agent is methyl isobutyl ketone, and the ratio of solvent to sewage is 1:6. The theoretical number of stages of the solvent recovery tower is 20, the pressure at the top of the tower is 0.11MPa, the temperature is 110°C, the pressure at the bottom of the tower is 0.12MPa, the temperature is 215°C, and the reflux ratio is 0.5. The total phenol content in the treated wastewater is 260mg·L -1 , the phenol content in the recovery extraction solvent is about 74mg / l -1 , the content of extractant in crude phenol is about 750mg / l -1 . The removal rate of phenol was 95.4%, and the calibrated extraction grade was 5 grades.

Embodiment 3

[0044] The total phenol content of the coal gasification wastewater entering the packed extraction tower is 5540mg·L -1 , the pH value is 6.5, the water temperature is 50°C, and the flow rate is 80 tons / hour.

[0045] The extraction tower adopts a packed tower, the height of the packing layer is 17.5m, the extractant is diisopropyl ether, and the ratio of solvent to sewage is 1:10. The theoretical number of stages of the solvent recovery tower is 20, the pressure at the top of the tower is 0.11MPa, the temperature is 68°C, the pressure at the bottom of the tower is 0.12MPa, the temperature is 200°C, and the reflux ratio is 0.5. The total phenol content in the treated wastewater is 350mg·L -1 , the phenol content in the recovery extraction solvent is about 80mg / l -1 , the content of extractant in crude phenol is about 280mg / l -1 . The removal rate of phenol was 93.6%, and the calibrated extraction grade was 5 grades.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com