Method for treating coal gasification wastewater

A technology of coal gasification wastewater and treatment methods, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problem of pollutants not being removed more effectively, failing to meet environmental protection requirements, organic pollution Complexity and other problems, to achieve the effect of improving biodegradability, short oxidation time, and improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

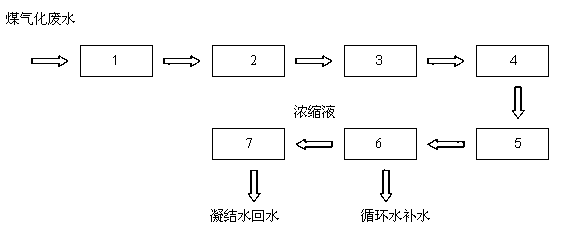

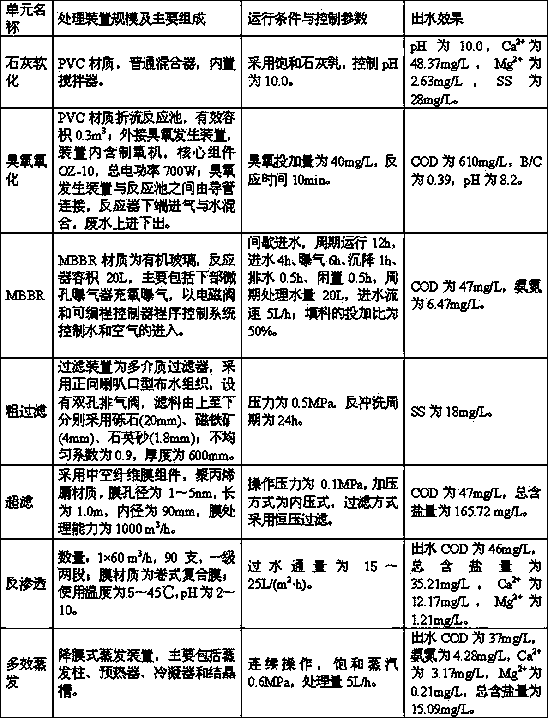

[0032] Adopt the method of the present invention to attach figure 1A combined process flow for the treatment of a certain coal gasification wastewater. The wastewater quality is as follows: pH is 7.3, COD is 961 mg / L, ammonia nitrogen is 141.49 mg / L, Ca2+ is 426.23 mg / L, Mg2+ is 12.52 mg / L, the total salt content is 1525.92 mg / L, and the B / C ratio is : 0.27. The wastewater treatment volume is 1000L, and the main test device configuration, operating conditions and treatment effects of each treatment unit are shown in Table 1.

[0033] Table 1 Main processing unit composition and processing effect of Embodiment 1

[0034]

[0035] The treated effluent water quality: COD is 40mg / L, ammonia nitrogen is 3.91mg / L, Ca 2+ 6.33mg / L, Mg 2+ The total salt content is 0.98mg / L, the total salt content is 25mg / L, and the recovered water volume is 937L.

Embodiment 2

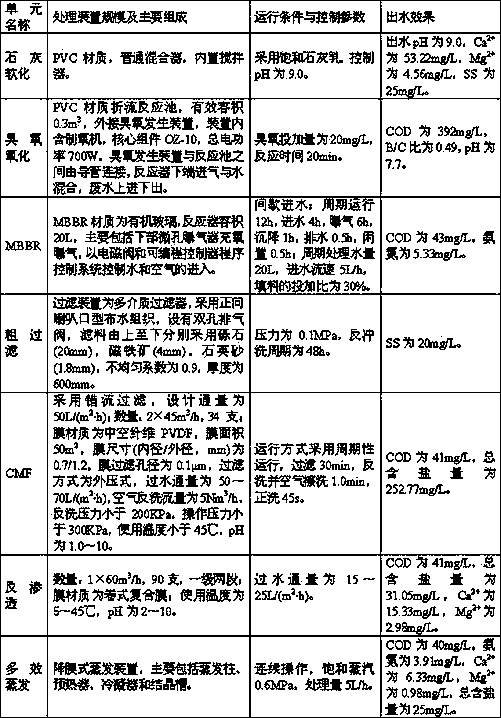

[0037] Adopt the method of the present invention to attach figure 1 A combined process flow for the treatment of a certain coal gasification wastewater. The wastewater quality is as follows: pH is 7.6, COD is 3326mg / L, ammonia nitrogen is 208.19 mg / L, Ca 2+ 369.83mg / L, Mg 2+ The total salt content was 12.14mg / L, the total salt content was 1553.6 mg / L, and the B / C was 0.21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com