Treatment and reclaimation method of coal gasification wastewater contg. phenol

A technology of coal gasification wastewater and recovery method, applied in chemical instruments and methods, water/sewage multi-stage treatment, extraction water/sewage treatment, etc. The effect of low processing cost, small footprint and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

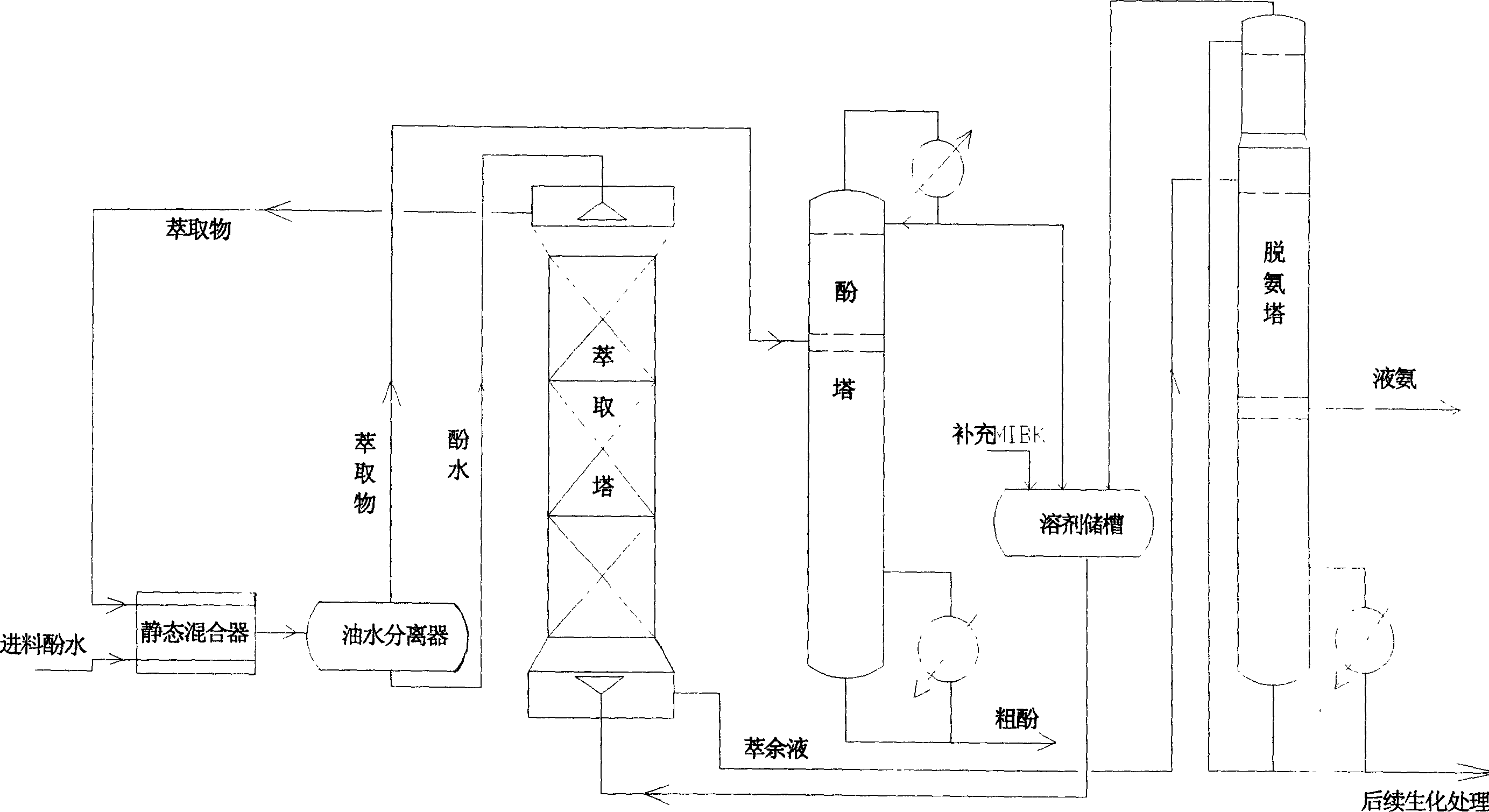

Image

Examples

Embodiment 1

[0030] (1) Wastewater to be treated

[0031] Select high-concentration phenol-containing coal gasification wastewater to be treated, with a treatment capacity of 100t / h, of which: the total phenol content is 5410mg·l -1 , of which 2750mg·l volatile phenol -1 ;Fatty acid about 3120mg·l -1 , total ammonia 7500mg·l -1 , oil content 350mg·l -1 ;COD Cr Value 22000mg·l -1 ; The pH value is 10, and the water temperature is 50°C.

[0032] (2) Disposal and recycling

[0033] according to figure 1 process as shown. The waste water to be treated enters the static mixer, and is mixed with the solvent methyl isobutyl ketone from the extraction tower in parallel, and the volume ratio (comparison) of the extraction solvent and waste water is 1:6. After being extracted by methyl isobutyl ketone, it enters the oil-water separator and stands still for 20 minutes. The upper solvent layer enters the crude phenol recovery rectification tower to separate the extractant methyl isobutyl ket...

Embodiment 2

[0036] (1) waste water to be treated, with embodiment 1;

[0037] (2) processing and recovery flow process are the same as embodiment 1, and its specific process conditions are as follows:

[0038] In the step (1), the industrial phenol-containing waste water and the extraction solvent are mixed in parallel in the static mixer, the pH of the waste water is 3, and the temperature is 85°C; the volume ratio of the solvent to the waste water is 1:10; the residence time of the waste water in the oil-water separator is 10min . The pH of the raffinate in the extraction tower is 11, the extraction temperature is 30°C, the extraction ratio is 10:1, and the number of extraction stages is 3. The extraction tower adopts honeycomb grid structured packing.

[0039] In step (2), the rectifying tower adopts a plate tower, the tower top pressure is 105kPa, the tower top temperature is 98±1°C, the tower still pressure is 130kPa, and the tower still temperature is 192±1°C; the reflux ratio is ...

Embodiment 3

[0044] (1) waste water to be treated, with embodiment 1;

[0045] (2) processing and recovery flow process are the same as embodiment 1, and its specific process conditions are as follows:

[0046] In the step (1), the industrial phenolic waste water and the extraction solvent are mixed in parallel in the static mixer, the pH of the waste water is 11, and the temperature is 30°C; the volume ratio of the solvent to the waste water is 10:1; the residence time of the waste water in the oil-water separator is 10min . In step (1), the pH of the raffinate in the extraction tower is 11, the extraction temperature is 30° C., the extraction ratio is 10:1, and the number of extraction stages is 8. The extraction tower adopts honeycomb grid structured packing.

[0047] In step (2), the rectifying tower adopts a plate tower, the tower top pressure is 120kPa, the tower top temperature is 98±1°C, the tower still pressure is 115kPa, and the tower still temperature is 192±1°C; the reflux ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com