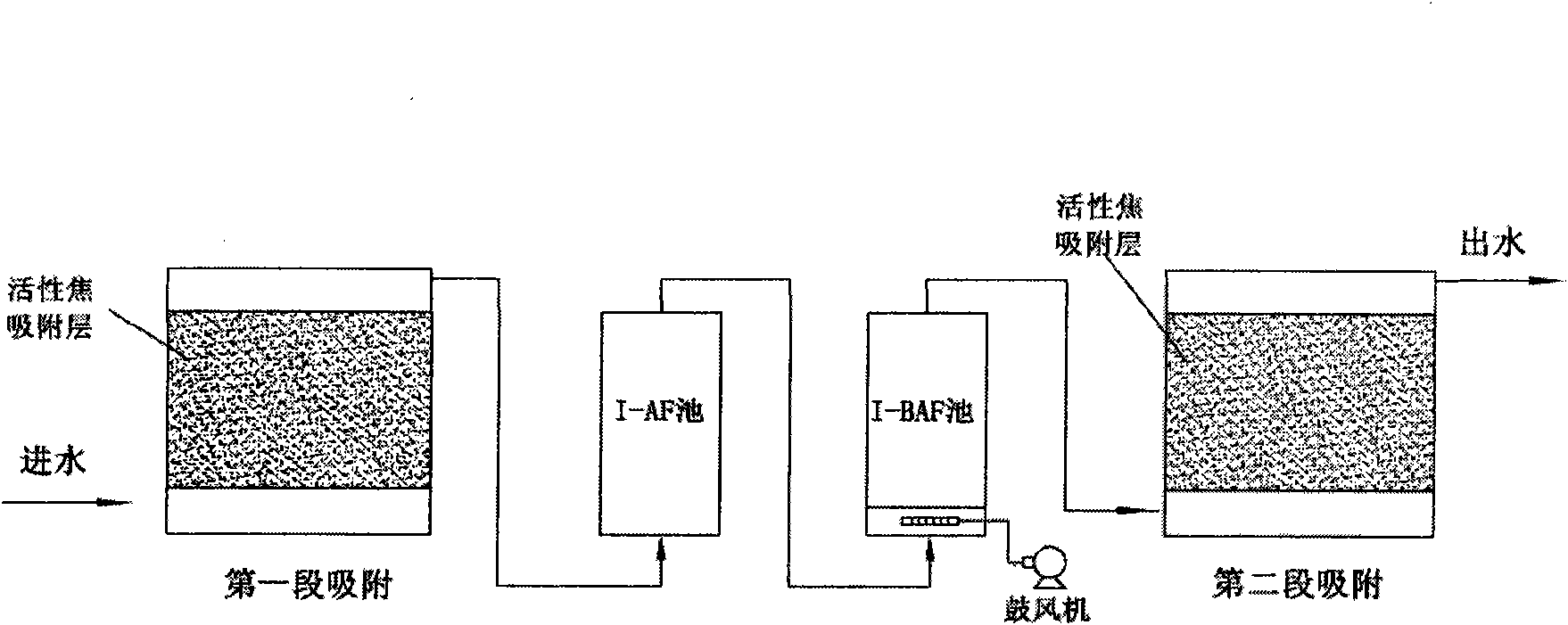

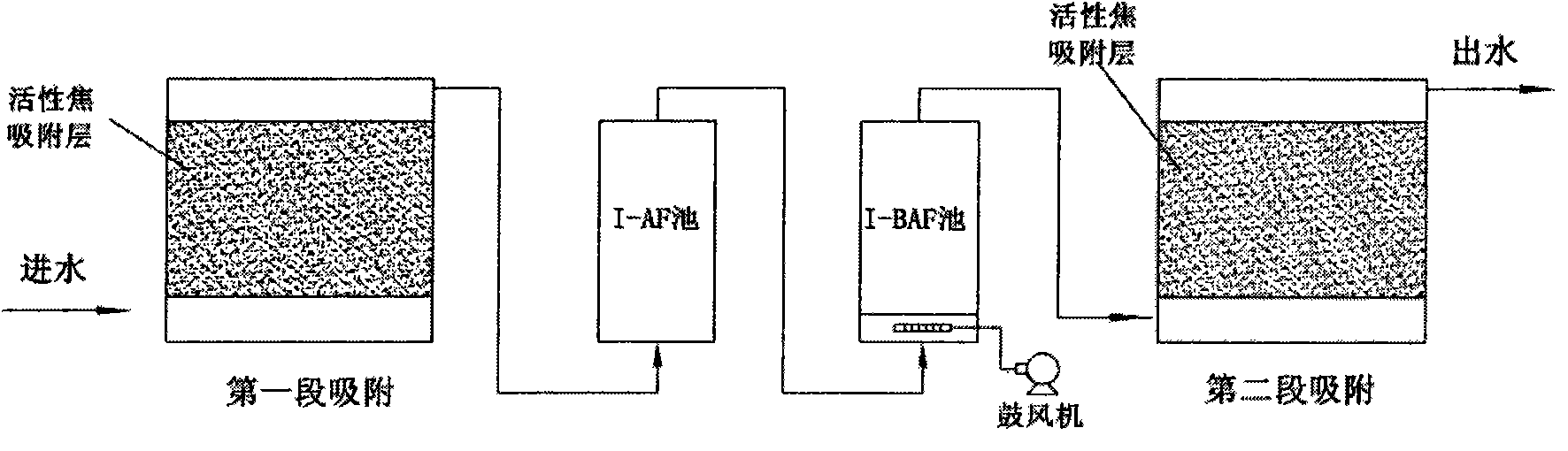

New process for treating coal gasification wastewater with active coke

A technology for coal gasification wastewater and activated coke, which is applied in the fields of water/sewage multi-stage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc. , membrane fouling and other problems, to achieve the effect of reducing the escape of volatile organic compounds, conducive to recycling and reuse, and low process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Using the present invention to treat coal gasification waste water from a coal gas plant, the hydraulic retention time of the first stage of adsorption is 6 hours, and the active coke with a particle size range of 0.45-0.9mm is added, and the dosage is 10kg / m 3 .Water, converted into activated coke, has a saturated adsorption capacity of 300 mg (COD) / g; the hydraulic retention time of I-AF and I-BAF is 24 hours, and the gas-water ratio is 30:1; the hydraulic retention time of the second stage of adsorption is 2 Hours, add active coke, dosage 1kg / m 3 .Water, converted into activated coke, has a saturated adsorption capacity of 90mg (COD) / g; the average COD at the water inlet is 3500mg / L, the average COD in the effluent is 30mg / L, and the removal rate is 99%; the average value of ammonia nitrogen in the influent is 450mg / L, The average value of effluent is 0.50mg / L, and the removal rate is 99.9%. The particle size ranges of the active coke particles in the first stage an...

Embodiment 2

[0021] Using the present invention to treat wastewater from a coking plant, the hydraulic retention time of the first stage of adsorption is 6 hours, and the active coke with a particle size range of 0.45-0.9mm is added, and the dosage is 12kg / m 3 .Water, converted into activated coke, has a saturated adsorption capacity of 290 mg (COD) / g; the hydraulic retention time of I-AF and I-BAF is 20 hours, and the gas-water ratio is 30:1; the hydraulic retention time of the second stage of adsorption is 4 Hours, add active coke, dosage 2kg / m 3 .Water, converted into activated coke, has a saturated adsorption capacity of 75mg (COD) / g; the average COD in the water inlet is 4000mg / L, the average COD in the effluent is 35mg / L, and the removal rate is 99%; the average value of ammonia nitrogen in the influent is 360mg / L, The average value of effluent is 0.30mg / L, and the removal rate is 99.9%. The particle size ranges of the active coke particles in the first stage and the second stage ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com