Phenol and ammonia wastewater recycling treatment method by using single tower for performing de-acidification and de-amination simultaneously

A technology of deacidification and deamination and treatment method, which is applied in the field of recovery and treatment of phenol ammonia wastewater using single tower deacidification and deamination at the same time, can solve the problems of high energy consumption and large equipment investment, and achieve simplified process flow and reduction of tower equipment , Reduce the effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

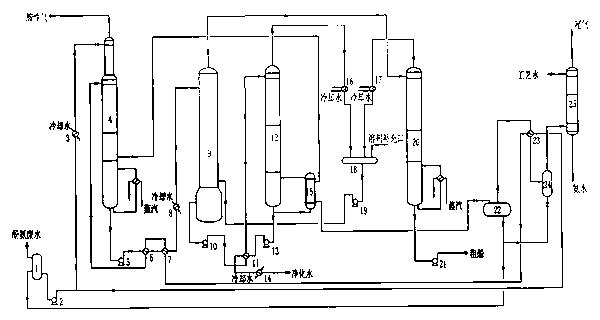

Method used

Image

Examples

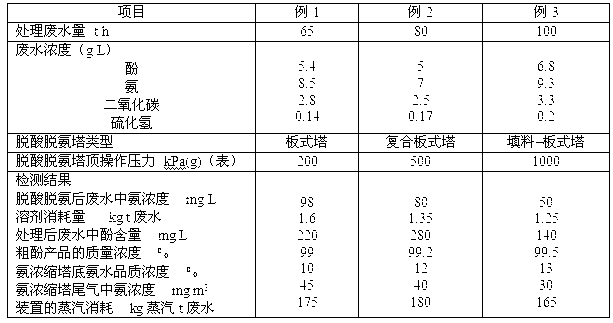

Embodiment 1

[0040] (1) After the 120t / h waste water is transported from the gas-water separator, the suspended solids, tar and light oil are removed, the temperature is 40°C, and the pressure is 1.0 MPa. The concentration is phenol 7g / L, ammonia 9g / L, carbon dioxide 3.8g / L, hydrogen sulfide 0.2g / L.

[0041] (2) The waste water containing phenol and ammonia from the gas-water separator is divided into two streams: one stream of 35t / h is cooled to room temperature by the raw material cooler (3) and then enters the top of the tower; the other stream passes through the secondary total condenser (23 ), preheater two (7), and preheater one (6) are heated to 95°C and enter the middle and upper part of the deacidification and deamination tower (4).

[0042] (3) The deacidification and deamination tower is a plate tower. The operating pressure of the deacidification and deamination tower is 500kPa(g) (gauge pressure), the temperature at the top of the tower is 85°C, and the temperature at the bot...

example 1

[0050] (1) The concentration of ammonia in the wastewater after deacidification and deamination is 95 mg / L.

[0051] (2) The solvent consumption is 1.25kg / t waste water.

[0052] (3) The phenol content in the treated wastewater is 200 mg / L.

[0053] (4) The mass concentration of the crude phenol product is 99.4%.

[0054] (5) The quality concentration of ammonia water at the bottom of the ammonia concentration tower is 12%, and the concentration of ammonia in the tail gas is 38 mg / m3.

[0055] (6) The steam consumption of the device is 170kg steam / t waste water.

Embodiment 3

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com