Purification technology for ammonia recycled from wastewater from coal gasification

A coal gasification wastewater and purification process technology, applied in the preparation/separation of ammonia, water pollutants, chemical instruments and methods, etc., can solve the problems of ammonia impurities and cannot be reused, so as to avoid environmental pollution and improve utilization rate , the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

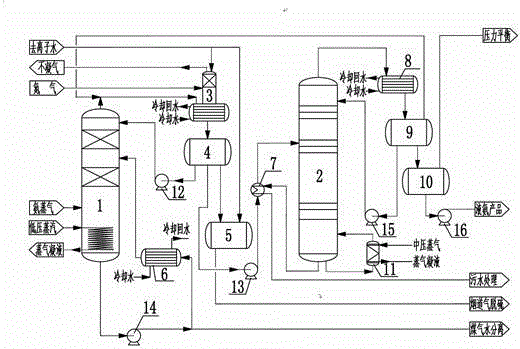

[0029]The ammonia purification device of the present embodiment consists of a purification tower 1, a rectification tower 2, a condensation absorber 3, an ammonia water tank 4, a dilute ammonia water tank 5, a circulating cooler 6, an ammonia water preheater 7, an ammonia condenser 8, and a liquid ammonia storage tank. Tank 9, liquid ammonia tank 10, rectification tower reboiler 11, purification tower reflux pump 12, rectification tower feed pump 13, ammonia circulation pump 14, rectification tower reflux pump 15, liquid ammonia pump 16, which are connected The method is: the crude ammonia feed pipeline is connected to the lower part of the purification tower 1, the outlet at the bottom of the purification tower is connected to the circulation feed port in the middle of the two packing sections of the purification tower through the ammonia water circulation pump 14 and the circulation cooler 6, and the outlet at the top of the purification tower is The ammonia gas outlet is res...

Embodiment 2

[0035] The composition, connection mode and process route of the ammonia purification device in this embodiment are detailed in Example 1

[0036] The ammonia purification process route and process conditions that the present embodiment adopts are:

[0037] (1) The composition of 60°C and 0.30MPa from the stripping deamination tower of the coal gasification wastewater treatment plant is NH 3 87wt%, H 2 O 10wt%, H 2 S 0.8wt%, CO 2 2.15 wt% and oil CO 2 0.05wt%, phenol 6000mg / m 3 Crude ammonia gas enters the purification tower 1 from the bottom, and is heated to 70°C by the low-pressure steam at the bottom of the purification tower 1. The ammonia vapor first passes through the lower packing section in the purification tower and the dilute ammonia water reflux liquid with a mass concentration of 30wt% at the bottom of the purification tower 1 is reversed. Contact washing, then countercurrent contact washing with dilute ammonia water with a concentration of 30wt% from the top...

Embodiment 3

[0041] The composition, connection mode and process route of the ammonia purification device in this embodiment are detailed in Example 1

[0042] The ammonia purification process route and process conditions that the present embodiment adopts are:

[0043] (1) The composition of 55°C and 0.25MPa from the stripping deamination tower of the coal gasification wastewater treatment plant is NH 3 88wt%, H 2 O 8.4wt%, H 2 S 0.55wt%, CO 2 3.0 wt% and oil CO 2 0.05wt%, phenol 5000mg / m 3 Crude ammonia gas enters the purification tower 1 from the bottom, and is heated to 68° C. by the low-pressure steam at the bottom of the purification tower 1. The ammonia vapor first passes through the lower packing section in the purification tower 1 and the dilute ammonia water reflux liquid with a mass concentration of 20 wt% at the bottom of the purification tower 1. Reverse contact washing, and then through the upper packing section and the dilute ammonia water with a reflux concentration of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com