Method of treating coal gasification wastewater

A technology of coal gasification wastewater and treatment method, which is applied in the fields of gaseous discharge wastewater treatment, degassed water/sewage treatment, oxidized water/sewage treatment, etc., and can solve the problem of not providing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

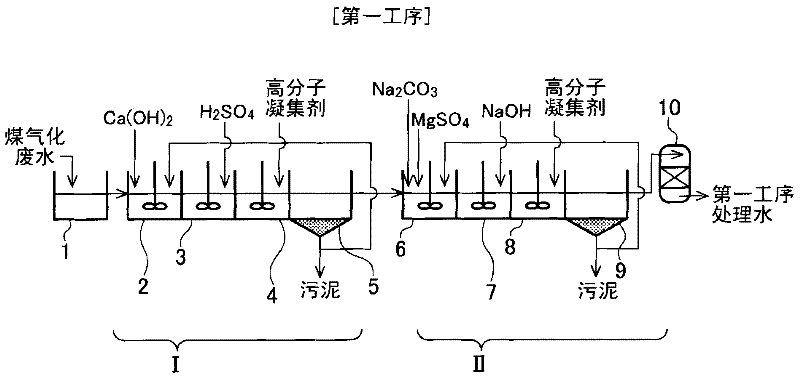

[0213] according to Figure 5 The treatment sequence shown is for the treatment of coal gasification wastewater.

[0214] The treatment conditions and the like in each step are as follows.

[0215] (Process (1): Coagulation and precipitation treatment of SS and fluorine)

[0216] according to the following conditions figure 1 Shown based on addition of Ca salt (using Ca(OH) 2 ) coagulation precipitation treatment and based on the addition of Mg salt (using MgSO 4 ) coagulation and precipitation treatment.

[0217] (Ca aggregation condition)

[0218] Ca addition amount = 2500mg / L (as Ca)

[0219] pH=7

[0220] Polymer coagulant: anionic polymer coagulant "Kurifarm PA893" manufactured by Kurita Kogyo Co., Ltd., with an addition amount of 3 mg / L.

[0221] (Mg aggregation condition)

[0222] (Implemented for supernatant water treated with Ca coagulation and precipitation)

[0223] Mg addition amount = 500mg / L (as Mg)

[0224] pH=11

[0225] Polymer coagulant: Kurifloc...

Embodiment 2

[0260] The treated water of the simulated process (2) prepared simulated wastewater with the following water quality, and carried out selenium treatment based on the Al / Ti method under the following conditions. Apart from image 3 This treatment was performed in the same manner except that aluminum and titanium were used as the metal reducing agent.

[0261] (raw water quality)

[0262] T-Se=5mg / L(Se(Ⅵ))

[0263] COD Mn =490mg / L (formic acid=4900mg / L)

[0264] NH 4 -N=4900mg / L

[0265] (based on reducing agent processing conditions)

[0266] Reductant: Al / Ti=1 / 1 (volume ratio)

[0267] Temperature: 65°C

[0268] Dissolution of Al: 1500mg / L

[0269] SV: 5 / hr (relative to Al)

[0270] (agglutination condition)

[0271] pH=7

[0272] Table 2 shows the processing results.

[0273] Table 2

[0274] project

[0275] As can be seen from Table 2, the selenium treatment by the Al / Ti method can sufficiently remove selenium as in the case of using an iron reducin...

Embodiment 3

[0277] according to Image 6 The treatment sequence shown is for the treatment of coal gasification wastewater.

[0278] In steps (1) to (4), the treatment conditions and treatment order of steps (1) to (3) are the same as those in Example 1.

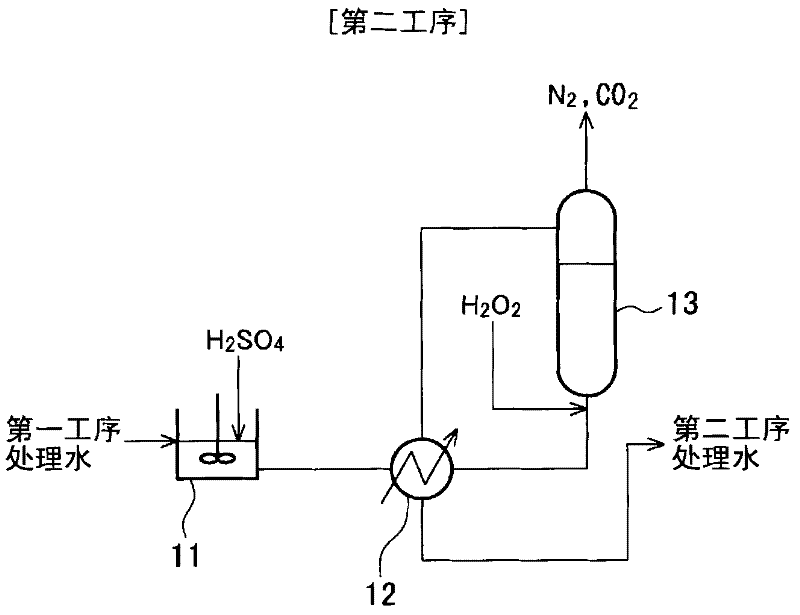

[0279] Wherein, in step (2), H 2 o 2 The addition amount was set at 4000 mg / L, and the reaction time was set at 1 hr.

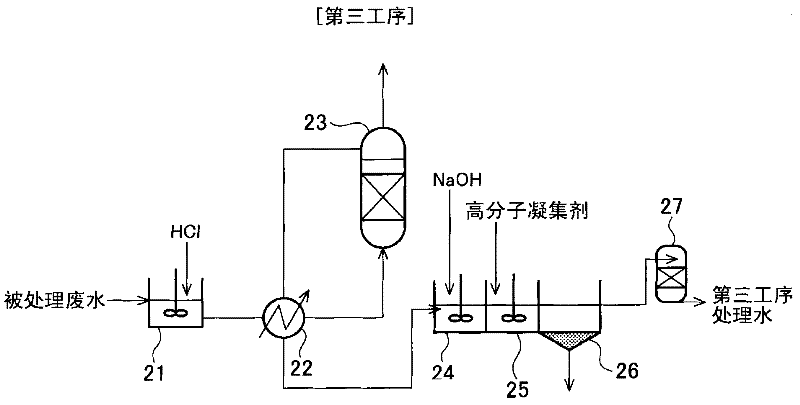

[0280] In addition, in the step (3), the amount of HCl added was set to be an amount such that the eluted iron amount became 1600 mg / L.

[0281] The treatment conditions of the step (4) are as follows.

[0282] (Process (4): ammonia stripping)

[0283] It implements with respect to the treated water of process (3).

[0284] NaOH was added to the wastewater to adjust the pH to 10, and then it was supplied from the upper part of a packed tower type diffuser filled with cascade ring packing, and steam and air were blown in from the lower part.

[0285] (air stripping conditions)

[0286] G / L=500 (air / wastewater vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com