A kind of treatment method of nitrile rubber production wastewater

A technology for producing waste water and nitrile rubber, which is applied in natural water treatment, water/sewage multi-stage treatment, adsorption water/sewage treatment, etc., can solve the problems of high acrylonitrile content and long treatment time, and achieve high effluent quality, The effect of the treatment effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

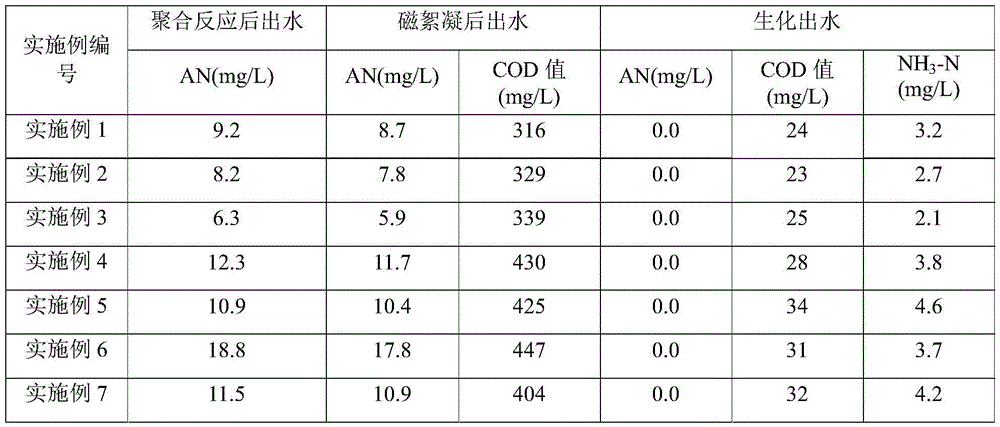

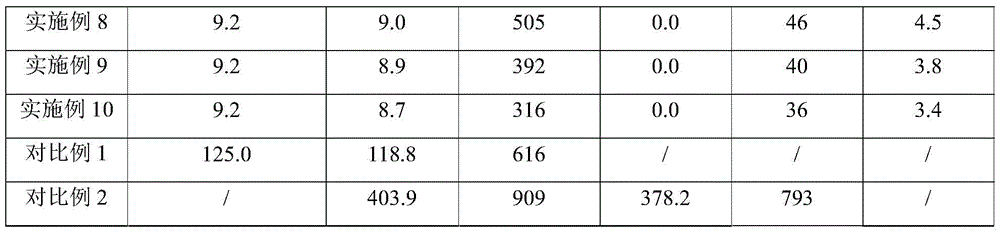

Embodiment 1

[0042] The pH value of wastewater 1 was adjusted to 4, and sodium persulfate and sodium sulfite were added thereto. The dosages in 1L of wastewater were 4000mg and 1500mg respectively, and the reaction time was 20min. The above wastewater enters the magnetic flocculation unit, that is, adjust the pH to 6, add magnetic powder, aluminum sulfate and polyacrylamide, and the dosage in 1L of wastewater is 120mg, 65mg and 1.2mg respectively, and stir rapidly (250r / min) for 2min. Stir at a slow speed (50r / min) for 6 minutes and let stand for 12 minutes. Put the supernatant into the activated sludge treatment unit, that is, add powdered activated carbon to the activated sludge (the weight ratio of powdered activated carbon to activated sludge is 0.12:1), and the sludge load is 0.18kgCOD / (kg sludge d), the amount of activated sludge is 3000mg / L wastewater, the dissolved oxygen in the control treatment system is 2mg / L, the temperature is 35°C, the pH value is 6.5, and the hydraulic reten...

Embodiment 2

[0044] Potassium persulfate and potassium sulfite were added to waste water 2, the dosing amount in 1L of waste water was 2000mg and 1000mg respectively, and the reaction time was 17min. The above wastewater enters the magnetic flocculation unit, that is, adjust the pH to 6, add magnetic powder, polyferric sulfate and polyacrylamide, and the dosage in 1L of wastewater is 150mg, 80mg and 1.5mg respectively, and stir rapidly (250r / min) for 3min , stirring slowly (50r / min) for 7 minutes, and standing for 13 minutes. Put the supernatant into the activated sludge treatment unit, that is, add powdered activated carbon to the activated sludge (the weight ratio of powdered activated carbon to activated sludge is 0.17:1), and the sludge load is 0.18kgCOD / (kg sludge d), the amount of activated sludge is 2800mg / L wastewater, the dissolved oxygen in the control treatment system is 4mg / L, the temperature is 25°C, the pH value is 7.5, and the hydraulic retention time is 16h. See Table 2 fo...

Embodiment 3

[0046] Add ammonium persulfate and ammonium sulfite to wastewater 3, the dosages in 1L of wastewater are 1000mg and 500mg respectively, and the reaction time is 25min. The above wastewater enters the magnetic flocculation unit, that is, adjust the pH to 6, add magnetic powder, polyferric chloride and polyacrylamide, and the dosage in 1L of wastewater is 170mg, 90mg and 1.7mg respectively, and stir rapidly (250r / min) 1min, stir slowly (50r / min) for 8min, and let stand for 14min. The supernatant after standing still enters the activated sludge treatment unit, that is, powdered activated carbon is added to the activated sludge (the weight ratio of powdered activated carbon to activated sludge is 0.15:1), and the sludge load is 0.21kgCOD / (kg sludge d), the amount of activated sludge is 3200mg / L wastewater, the dissolved oxygen in the control treatment system is 3mg / L, the temperature is 30°C, the pH value is 7.0, and the hydraulic retention time is 12h. See Table 2 for the proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com