Catalyst for gas-phase polymerization or copolymerization of ethylene and preparation method thereof

A gas-phase polymerization and catalyst technology, which is applied in the production of bulk chemicals, etc., can solve the problems of reducing the performance of polyethylene resin products and unsatisfactory polymerization product forms, and achieve good particle shape, high polymerization activity, and less fine powder. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

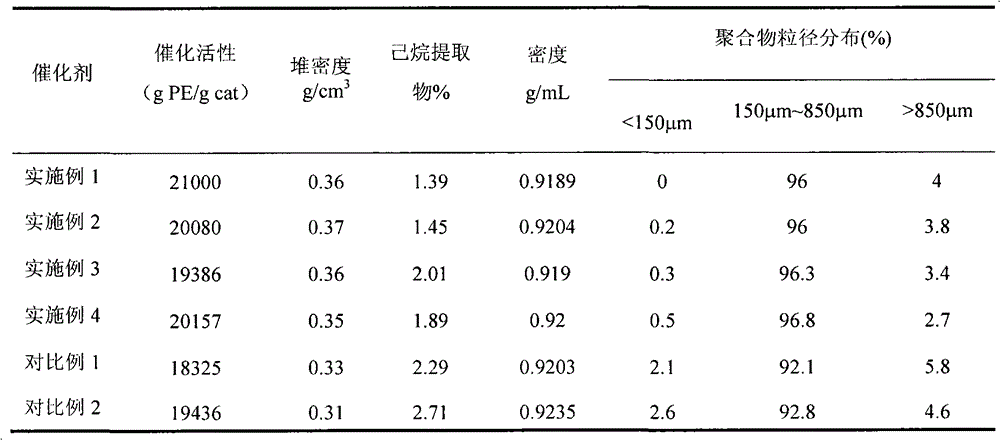

Examples

Embodiment 1

[0021] (1), catalyst preparation:

[0022] to pass through N 2 Add 5.0g TiCl to the fully replaced 500mL catalyst preparation reactor 3 , 9.0 g MgCl 2 and 220mL tetrahydrofuran, heated to 65°C under stirring, reacted at constant temperature for 2 hours, added sorbitan ester (span80) at a ratio of 1:0.3 by the molar ratio of Mg to surfactant, reacted at constant temperature at 65°C for 3 hours, cooled to room temperature.

[0023] to the other via N 2 After adding 13.5 grams of silica gel (0.02-0.1 μm in particle size) into a fully replaced 500mL reactor, add the cooled mother liquor and stir for 2 hours. Use a spray dryer to spray-dry the mother liquor, spray Conditions: the inlet temperature is 150°C, the outlet temperature is 90°C, and the solid catalyst component is obtained, wherein the Ti content is 2.28% (wt), the Mg content is 5.91% (wt), and the THF content is 28.3% (wt). Add mineral oil in the solid catalyst component that obtains, be made into the mineral oil so...

Embodiment 2

[0027] (1), catalyst preparation:

[0028] to pass through N 2 Add 5.0g TiCl to the fully replaced 500mL catalyst preparation reactor 3 , 9.0 g MgCl 2 and 220mL tetrahydrofuran, heated to 65°C under stirring, reacted at constant temperature for 2 hours, added hexadecyltrimethylammonium bromide at a ratio of 1:0.3 in the molar ratio of Mg to surfactant, and reacted at constant temperature at 65°C for 3 hours, Cool to room temperature.

[0029] to the other via N 2After adding 13.5 grams of silica gel (0.02-0.1 μm in particle size) into a fully replaced 500mL reactor, add the cooled mother liquor and stir for 2 hours. Use a spray dryer to spray-dry the mother liquor, spray Conditions: the inlet temperature is 150°C, the outlet temperature is 90°C, and the solid catalyst component is obtained, wherein the Ti content is 2.35% (wt), the Mg content is 6.02% (wt), and the THF content is 26.2% (wt). Add mineral oil in the solid catalyst component that obtains, be made into the mi...

Embodiment 3

[0033] (1) Catalyst preparation:

[0034] to pass through N 2 Add 5.0g TiCl to the fully replaced 500mL catalyst preparation reactor 3 , 9.0 g MgCl 2 and 220mL tetrahydrofuran, heated to 65°C under stirring, reacted at constant temperature for 2 hours, added sodium dodecylbenzenesulfonate at a ratio of 1:0.3 in the molar ratio of Mg to surfactant, reacted at constant temperature at 65°C for 3 hours, and cooled to room temperature.

[0035] to the other via N 2 After adding 13.5 grams of silica gel (0.02-0.1 μm in particle size) into a fully replaced 500mL reactor, add the cooled mother liquor and stir for 2 hours. Use a spray dryer to spray-dry the mother liquor, spray Conditions: the inlet temperature is 150°C, the outlet temperature is 90°C, and a solid catalyst component is obtained, wherein the Ti content is 2.31% (wt), the Mg content is 5.82% (wt), and the THF content is 30.1% (wt). Add mineral oil in the solid catalyst component that obtains, be made into the minera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com