A kind of catalyst system for the selective oligomerization of ethylene to prepare 1-octene, its preparation method and application

An ethylene oligomerization and selective technology, applied in chemical instruments and methods, physical/chemical process catalysts, compounds of elements of Group 5/15 of the periodic table, etc., can solve the problem of high oligomer content, 1-octene selection Problems such as low sex, to achieve high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

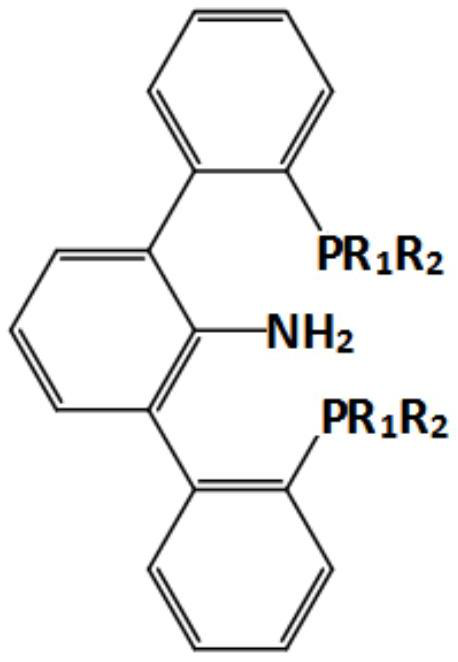

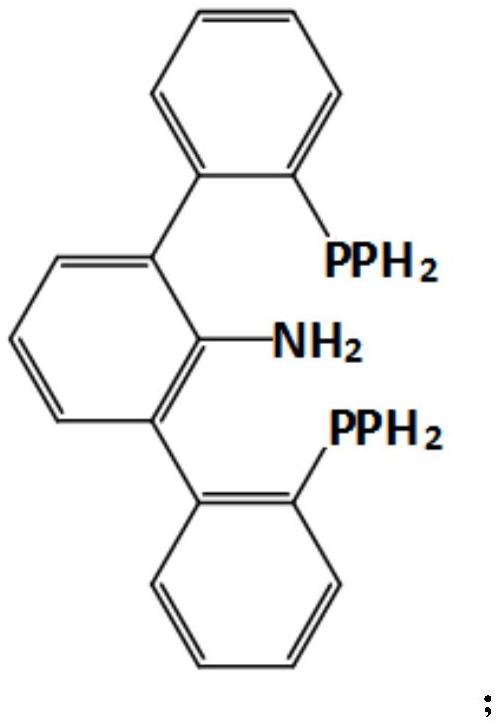

[0046] Preparation of Ligand Compound 1

[0047] Preparation of 2,5-bis(2-diphenylphosphine-phenyl)aniline: add (2-bromophenyl)-diphenylphosphine (2.4g , 7mmol, analytically pure, purchased from Aladdin Reagent Company), 2,5-diaminophenylboronic acid (633mg, 3.5mmol, analytically pure, purchased from Aladdin Reagent), [1,1′-bis(diphenylphosphine Base) ferrocene] palladium dichloride (143mg, 0.18mmol, analytically pure, purchased from Aladdin reagents), anhydrous potassium phosphate (2.3g, 11.5mmol, analytically pure, purchased from Aladdin reagents). Transfer the sealed tube to a glove box with an argon atmosphere, add 30 mL of anhydrous 1,4-dioxane (analytical grade, purchased from Aladdin reagent), seal the sealed tube with a cock, take it out, and heat it in an oil bath for 100- React at 105°C for 16 hours. Heating was stopped, and after cooling to room temperature, 20 mL of water was added to quench the reaction, the aqueous phase was extracted with ethyl acetate (analytic...

Embodiment 1

[0051] This example provides a catalyst system for the selective oligomerization of ethylene to produce 1-octene, which includes three components: ligand A, transition metal compound B, and activator C;

[0052] The ligand A is 2,5-bis(2-diphenylphosphine-phenyl)aniline (ligand compound 1), and the transition metal compound B is CrCl 3 (THF), activator C is methylaluminoxane (MAO);

[0053] The above-mentioned catalyst system is used for ethylene oligomerization to prepare 1-octene, and the specific steps are as follows:

[0054] Step 1: Add 100mL cyclohexane and MAO (Al: 5.0mmol) into a 300mL stainless steel reactor replaced by nitrogen, then heat to a temperature of 50°C;

[0055] Step 2: In a nitrogen atmosphere glove box, the CrCl in 20mL toluene 3 (THF) 3 3.7mg (0.010mmol) was added to a 50mL flask, followed by 6.1mg (0.010mmol) of 2,5-bis(2-diphenylphosphine-phenyl)aniline (ligand compound 1), and the mixture was stirred at room temperature 5min, then it is added in...

Embodiment 2

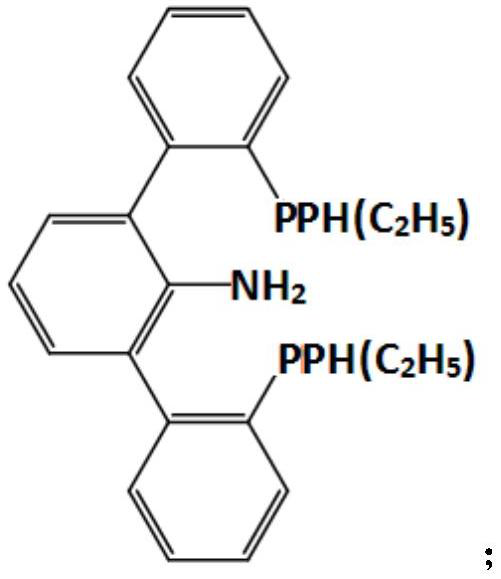

[0058] The difference between this embodiment and Example 1 is that ligand A is ligand compound 2 (C34H33NP 2 ), the addition amount is 5.2mg (0.010mmol). The quality and proportion of various products obtained, and the catalyst activity are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com