Method for preparing partially crosslinked hydroexpansivity acrylate-acrylic acid copolymer

An acrylate and cross-linked technology, which is applied in the field of preparation of partially cross-linked water-swellable acrylate-acrylic acid copolymers, can solve the problems of large investment, high operation requirements and unstable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

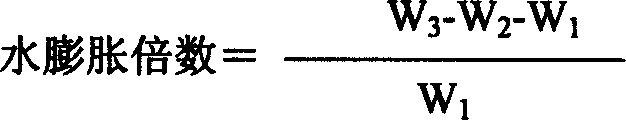

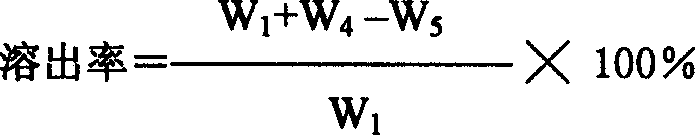

Image

Examples

Embodiment 1

[0020] A preparation method of a partially cross-linked water-swellable sodium acrylate-acrylic acid copolymer: Weigh 72 g of acrylic acid and put it into a container with stirring, a thermometer, and an ice-water bath. Weigh 90 g of 30% sodium hydroxide solution, add 45 g of water to make the sodium hydroxide solution 20%, and transfer it to the dropping funnel. Start stirring, slowly add sodium hydroxide solution dropwise, control the neutralization reaction temperature below 30°C, add crosslinking agent N, N'-methylenebisacrylamide 0.002g, photoinitiator benzoin after completion of neutralization reaction Isopropyl ether 0.002g. Nitrogen for 45 minutes, put into a transparent container, and seal it for later use.

[0021] Put the liquid in the transparent container under the ultraviolet lamp, adjust the distance so that the light intensity of the ultraviolet lamp is 5000μw / cm 2 , irradiated for 5h, the polymerization reaction was completed, and a copolymer gel was obtaine...

Embodiment 2-9

[0025] Implementation steps are the same as in Example 1, and the ratio of each component, light conditions, and performance are shown in Table 1

[0026] implement

Example 2

implement

Example 3

implement

Example 4

implement

Example 5

implement

Example 6

implement

Example 7

implement

Example 8

implement

Example 9

Group

Minute

acrylic

34.0

36.5

31.7

28.6

35.6

28.6

25.5

23.8

9.4

12.7

15.4

11.9

14.9

11.9

10.6

9.9

Deionized water

56.6

50.8

52.9

59.5

49.5

59.5

63.8

66.2

cross-linking

agent

quantity

0

0.001

0.002

0.002

0.002

0.005

0.01

0.02

type

a

b

c

d

e

f

a+b

Hairspray

quantity ...

Embodiment 10

[0035] A preparation method of a partially cross-linked water-swellable potassium acrylate-acrylic acid copolymer: Weigh 72 g of acrylic acid, and put it into a three-necked flask equipped with stirring, a thermometer, and an ice-water bath. Weigh 42 g of potassium hydroxide, add 168 g of water to make the potassium hydroxide to a content of 20%, and transfer it to the dropping funnel. Start stirring, slowly add potassium hydroxide solution dropwise, control the neutralization reaction temperature to ≤30°C, and add 0.002g of N,N'-methylenebisacrylamide and 0.002g of benzoin isopropyl ether after the neutralization reaction is completed. Nitrogen flow for 45 minutes, put into plastic bags for later use.

[0036] Put the bagged material liquid under the ultraviolet lamp, adjust the distance so that the light intensity of the ultraviolet lamp is 5000μw / cm 2 , irradiated for 5h, the polymerization reaction was completed, and a copolymer gel was obtained.

[0037] The gel is shre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com