Narrow distribution linear phenolic resins and preparation method thereof

A technology of novolak resin and phenols, which is applied in the field of narrow distribution novolac resin and its preparation, which can solve the problems of long reaction time, affecting resin performance, and difficulty in process control, and achieves low oligomer content and narrow molecular weight distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

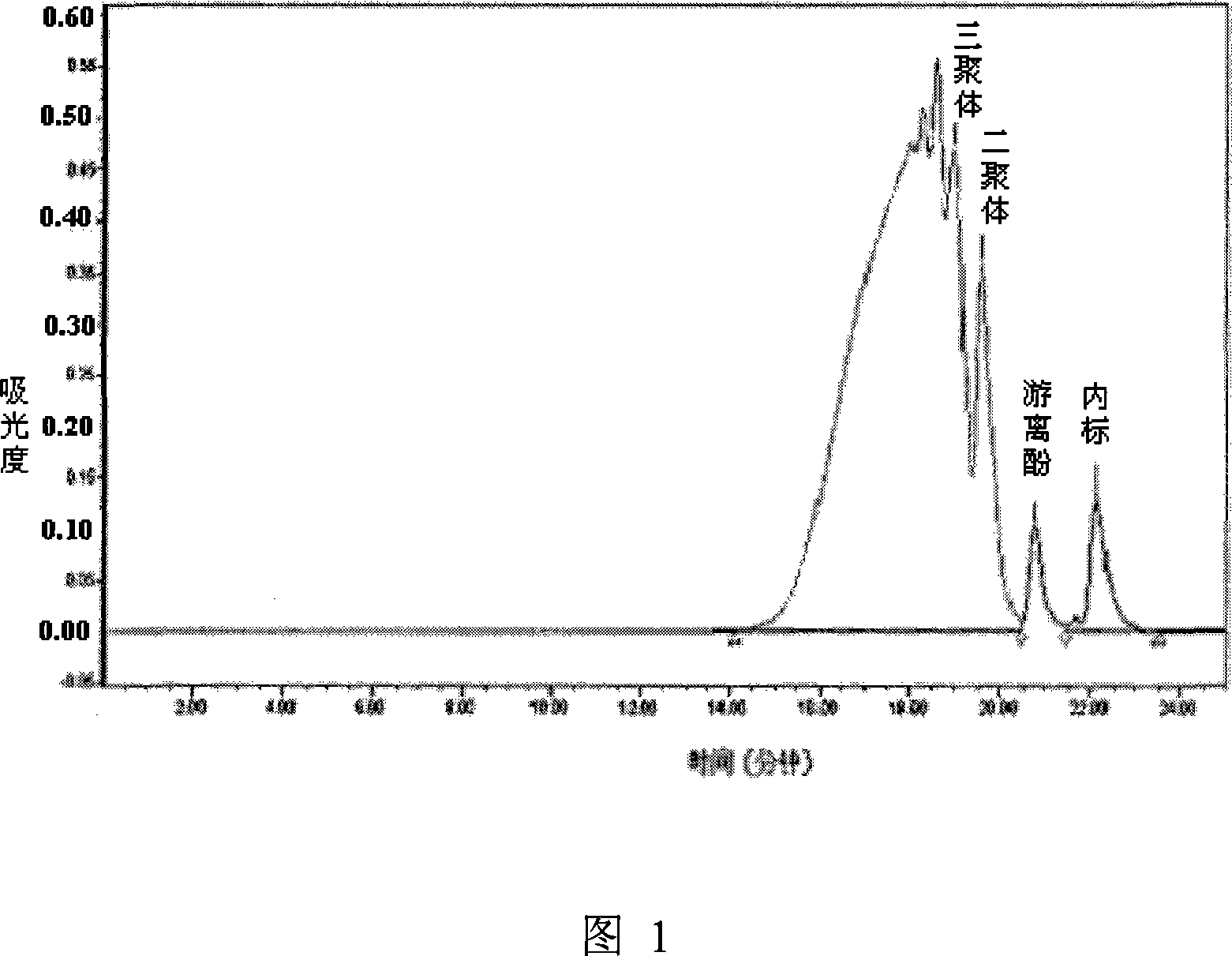

[0025] Phenol 502g, cardanol 38g, 37% formaldehyde aqueous solution 371g and lithium-based bentonite 100g, oxalic acid 10g are dropped into in the reaction container that has thermometer, agitator, reflux condenser, heat up to 80 ℃ constant temperature reaction 1 hour, then in Raise the temperature to 90°C, react at a constant temperature for 1 hour, and finally raise the temperature to 100°C, react at a constant temperature for 3 hours, end the reaction and carry out atmospheric distillation, heat to 150°C, and then dehydrate and dephenolize by vacuum distillation at -0.092MPa to obtain 656g of phenolic resin A. The GPC spectrogram of gained phenolic resin is shown in Fig. 1.

Embodiment 2

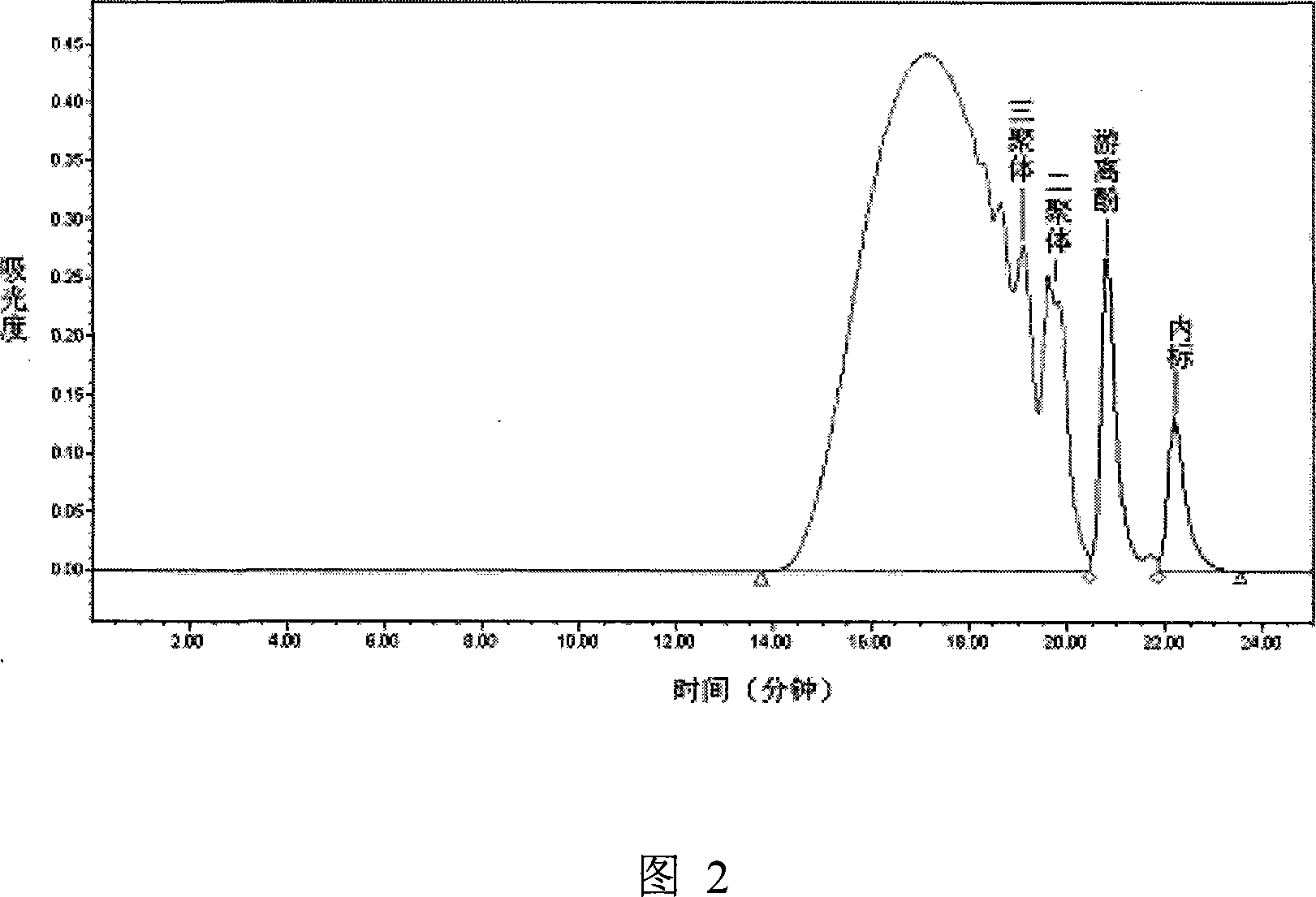

[0027] Put 445g of phenol, 324g of 37% formaldehyde solution, 90g of lithium-based bentonite, and 9g of oxalic acid into a reaction vessel with a thermometer, a stirring device, and a reflux condenser, heat up to 80°C for constant temperature reaction for 1 hour, and then heat up to 90°C , react at constant temperature for 1 hour, finally raise the temperature to 100°C, react at constant temperature for 3 hours, end the reaction and carry out atmospheric distillation, heat to 150°C, and then dehydrate and dephenolize by vacuum distillation at -0.092MPa to obtain 540g of phenolic resin B . The GPC spectrogram of the obtained phenolic resin is shown in Figure 2.

Embodiment 3

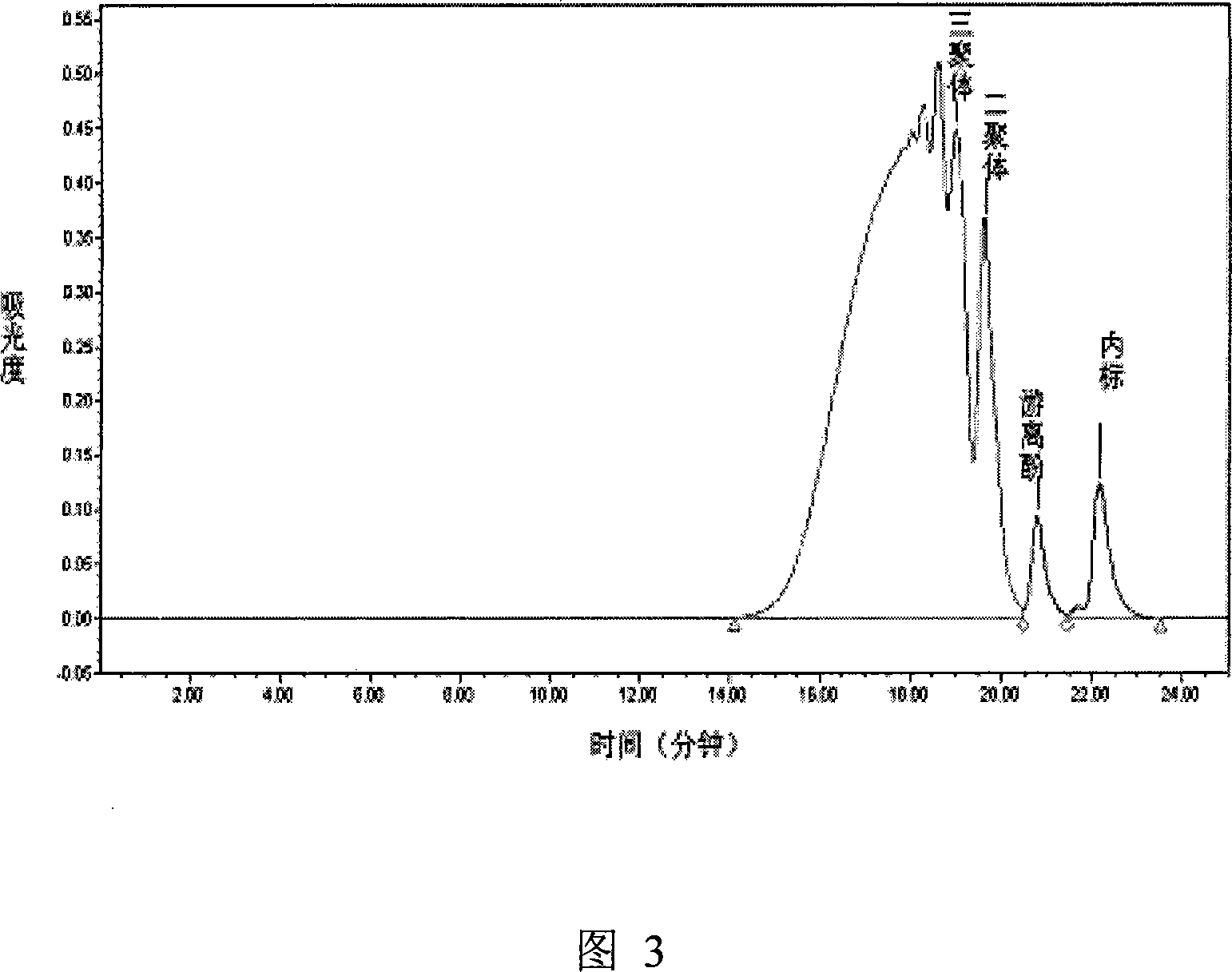

[0029] Phenol 325g, cardanol 16g, 37% formaldehyde solution 248g and lithium-based bentonite 65g, oxalic acid 6.5g are dropped into in the reaction container that has thermometer, stirring device, reflux condenser, heat up to 80 ℃ constant temperature reaction 1 hour, then Raise the temperature to 90°C, react at a constant temperature for 1 hour, and finally raise the temperature to 100°C, react at a constant temperature for 3 hours, end the reaction and carry out atmospheric distillation, heat to 150°C, and then dehydrate and dephenolize by vacuum distillation at -0.092MPa. Obtain 422g of phenolic resin C. The GPC spectrogram of the obtained phenolic resin is shown in Figure 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com