Olefin polymerization catalyst with double active components and preparation method

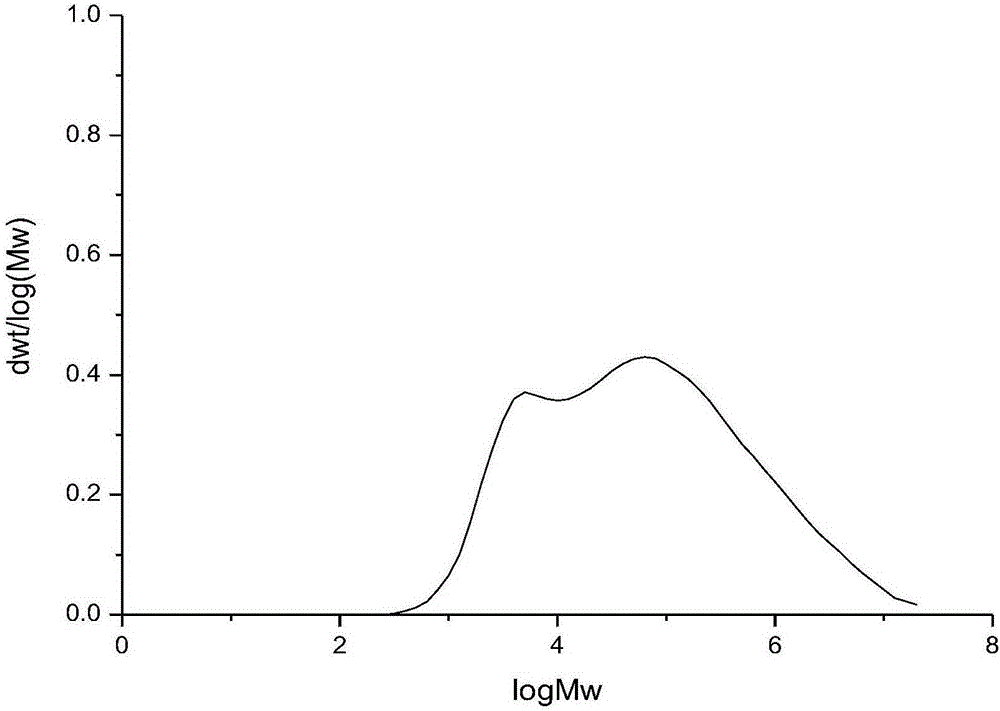

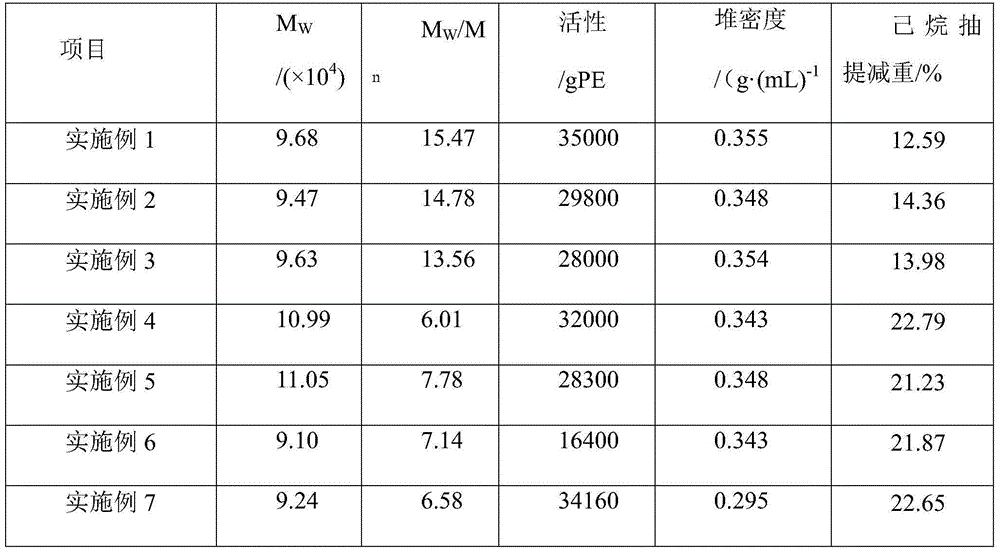

An olefin polymerization and catalyst technology, which is applied in the field of dual-active component olefin polymerization catalyst and its preparation, can solve the problems of difficult shape control and low bulk density, and achieve the effects of good material performance, good strength and improved comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) MgCl 2 Dissolve in ethanol solution, add dehydration activated SiO with particle size less than or equal to 1.0μm 2 , fully dispersed and sprayed to obtain a spherical composite carrier with good shape, the obtained spherical composite carrier is dealcoholized in a fluidized bed to make the MgCl in the spherical composite carrier 2 : SiO 2 : The molar ratio of ethanol is 1:1:0.1;

[0045] (2) The spherical composite carrier obtained by step (1) is dispersed in hexane, and the dispersant Ti(OBu) is added 4 , at 30°C, the carrier was pre-dispersed to obtain a suspension, and the dispersant and MgCl 2 The molar ratio is 0.01;

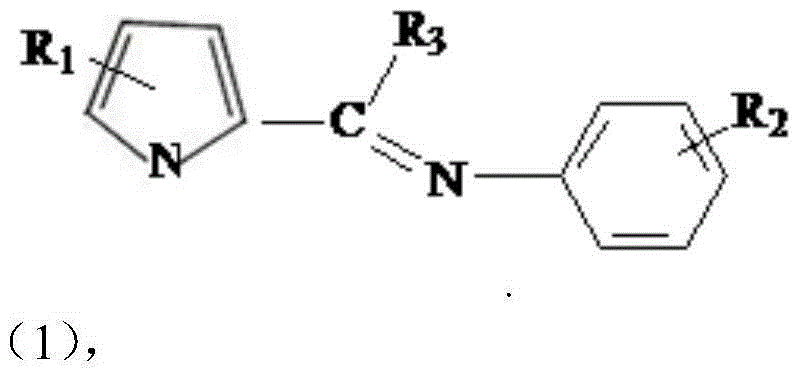

[0046] (3) Add N-(2,6-dimethylphenyl)-2-pyrrolemethimine to the suspension prepared in step (2), and fully react at 30°C for 0.1 hour. The N-(2 ,6-Dimethylphenyl)-2-pyrrolemethimine and MgCl 2 The molar ratio is 0.001;

[0047] (4) Add TiCl to the carrier suspension prepared in step (3) 4 and VCl 4 At 30°C, reacted for 0.5 hours, the Ti...

Embodiment 2

[0049] (1) MgCl 2 Dissolve in propanol solution, add dehydration-activated SiO with particle size less than or equal to 1.0μm 2 , fully dispersed and sprayed to obtain a spherical composite carrier with good shape, the obtained spherical composite carrier is dealcoholized in a fluidized bed to make the MgCl in the spherical composite carrier 2 : SiO 2 : Propanol molar ratio is 1:5:1;

[0050] (2) The spherical composite carrier obtained by step (1) is dispersed in heptane, and the dispersant Ti(OBu) is added 4 , at 80°C, the carrier was pre-dispersed to obtain a suspension, and the dispersant and MgCl 2 The molar ratio is 1.0;

[0051] (3) Add N-(2,6-diethylphenyl)-2-pyrrolemethimine to the suspension prepared in step (2), and fully react at 150°C for 1.5 hours. The N-(2 ,6-diethylphenyl)-2-pyrrolemethimine and MgCl 2 The molar ratio is 0.1;

[0052] (4) Add TiCl to the carrier suspension prepared in step (3) 4 and VCl 4 At 100°C for 12 hours, the TiCl 4 with MgCl 2...

Embodiment 3

[0054] (1) MgCl 2 Dissolve in butanol solution, add dehydration-activated SiO with particle size less than or equal to 1.0 μm 2 , fully dispersed and sprayed to obtain a spherical composite carrier with good shape, the obtained spherical composite carrier is dealcoholized in a fluidized bed to make the MgCl in the spherical composite carrier 2 : SiO 2 : Butanol molar ratio is 1:3:0.5;

[0055] (2) Disperse the spherical composite carrier obtained in step (1) in octane, add dispersant Ti(OBu) 4 , at 60°C, the carrier was pre-dispersed to obtain a suspension, and the dispersant and MgCl 2 The molar ratio is 0.66;

[0056] (3) Add N-(2,6-diisopropylphenyl)-2-pyrrolemethimine to the suspension prepared in step (2), and fully react at 120°C for 1.3 hours. The N-( 2,6-diisopropylphenyl)-2-pyrrolemethimine and MgCl 2 The molar ratio is 0.009;

[0057] (4) Add TiCl to the carrier suspension prepared in step (3) 4 and VCl 4 At 70°C for 11 hours, the TiCl 4 with MgCl 2 The mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com