Ethylene-alpha-olefin copolymer, manufacturing method and applications thereof

A technology of an olefin copolymer and a manufacturing method, which is applied in the field of ethylene copolymer and can solve the problems of poor processing performance and small application range of ultra-high molecular weight polyethylene.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

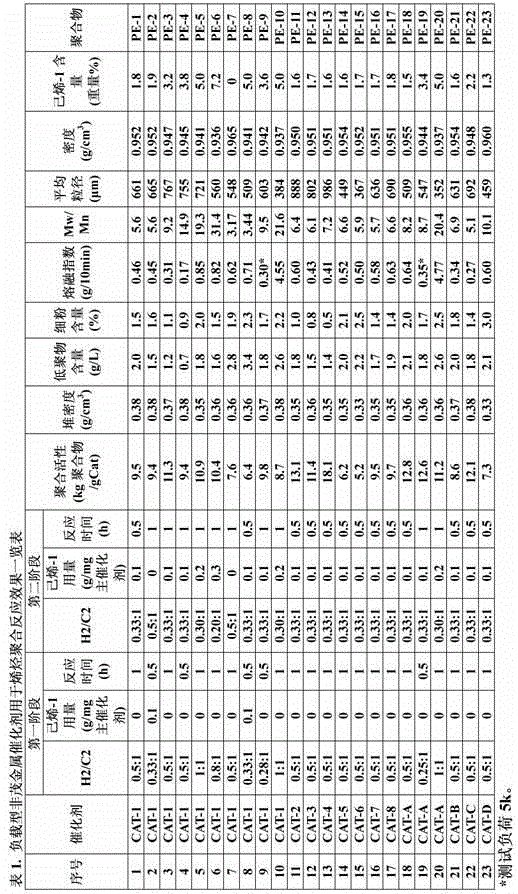

Examples

preparation example Construction

[0145] According to the present invention, the preparation method of the supported non-metallocene catalyst comprises the following steps: dissolving the magnesium compound and the non-metallocene ligand in a solvent in the presence of alcohol to obtain a solution of the magnesium compound; making the porous carrier and the Mixing the magnesium compound solution to obtain a mixed slurry; adding a precipitant to the mixed slurry or drying the mixed slurry to obtain a composite carrier; and chemically treating the composite carrier with a metal compound selected from Group IVB The step of obtaining the supported non-metallocene catalyst by contacting with the catalyst.

[0146] The steps for obtaining the magnesium compound solution are specifically described below.

[0147] According to this procedure, the magnesium compound and the non-metallocene ligand are dissolved in an appropriate solvent (also referred to as a solvent for dissolving the magnesium compound) in the presenc...

Embodiment 1

[0519] The magnesium compound adopts anhydrous magnesium chloride, and the non-metallocene ligand adopts the structure For the compound, tetrahydrofuran was used as the solvent, ethanol was used as the alcohol, and silicon dioxide was used as the porous carrier, that is, silica gel, the model of which was ES757 from Ineos Company. The IVB chemical treatment agent adopts titanium tetrachloride (TiCl 4 ).

[0520] Weigh 5 grams of magnesium compound, add it to the solvent, then add alcohol and non-metallocene ligands, completely dissolve at room temperature to obtain a magnesium compound solution, then add a porous carrier, stir for 2 hours to obtain a mixed slurry, and then uniformly heat to 90 °C, directly vacuum-dried to obtain a composite carrier.

[0521] Add the prepared composite carrier into the hexane solvent, add the IVB group chemical treatment agent dropwise within 30 minutes at room temperature, then evenly heat to 60°C and react at a constant temperature for 2 ho...

Embodiment 2

[0525] Basically the same as Example 1, but with the following changes:

[0526] Before the composite carrier is in contact with the chemical treatment agent, the composite carrier is first treated with the auxiliary chemical treatment agent triethylaluminum.

[0527] That is, the composite carrier was added to the hexane solvent, and then the auxiliary chemical treatment agent triethylaluminum (concentration: 0.88mol / L, hexane solution) was slowly added dropwise, stirred at 60°C for 2 hours, filtered, washed with hexane for 3 Each time, the amount of each solvent was the same as that of the previously added solvent, and finally vacuum-dried at 60° C. to obtain a supported non-metallocene catalyst. The molar ratio of the composite support in terms of Mg element to the auxiliary chemical treatment agent in terms of Al element is 1:0.2.

[0528] Supported non-metallocene catalysts are designated CAT-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com