Thermoplastic resin composition, method for producing same, and molded article produced using same

A thermoplastic resin and composition technology, applied in the field of thermoplastic resin composition, its preparation, and molded products manufactured using it, can solve the problems of reduced heat resistance, increased generation of residual oligomers, and reduced product yield, etc., to achieve Effects of excellent colorability, low processability and scratch resistance, excellent weather resistance and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0134]

[0135] In describing the method for preparing the thermoplastic resin composition of the present invention, all the contents of the thermoplastic resin composition described above are included.

[0136] For example, the method of preparing the thermoplastic resin composition is as follows.

[0137] For example, the method for preparing a thermoplastic resin composition may include a step of preparing a styrene-based copolymer by suspension polymerizing a polymerization solution prepared by adding 100 parts by weight of a (meth)acrylate-based monomer, an aromatic Group vinyl monomer, monomer mixture of maleimide monomer, 100 to 200 parts by weight of reaction solvent, 0.01 to 1 part by weight of initiator, 1 to 5 parts by weight of It is prepared by mixing a dispersant and 0.01 part by weight to 1 part by weight of a molecular weight regulator.

[0138] In the step of preparing the styrene-based copolymer, the reaction solvent may be water. In this case, the heat o...

Embodiment 1

[0165]

[0166]140 parts by weight of deionized water, 86 parts by weight of methyl methacrylate (hereinafter referred to as "MMA"), 4 parts by weight of N-phenylmaleimide (hereinafter referred to as "PMI"), 10 Parts by weight of styrene (hereinafter referred to as "SM"), 0.06 parts by weight of tert-butyl peroxybenzoate as an initiator, 1.3 parts by weight of tricalcium phosphate as a dispersant, and 0.2 parts by weight of tert-ten as a molecular weight regulator Dialkyl mercaptan was introduced into the reactor, and then the temperature was raised to 100°C at 500 rpm to start the polymerization reaction. The polymerization reaction was held for 6 hours. Thereafter, the polymerization reaction was completed.

[0167] To the prepared polymerization slurry, formic acid was added, its pH was adjusted to 2.5 to remove the dispersant, and then washing, dehydration, and drying were performed to prepare a bead-like styrenic copolymer. The prepared copolymer had a refractive inde...

Embodiment 2~6

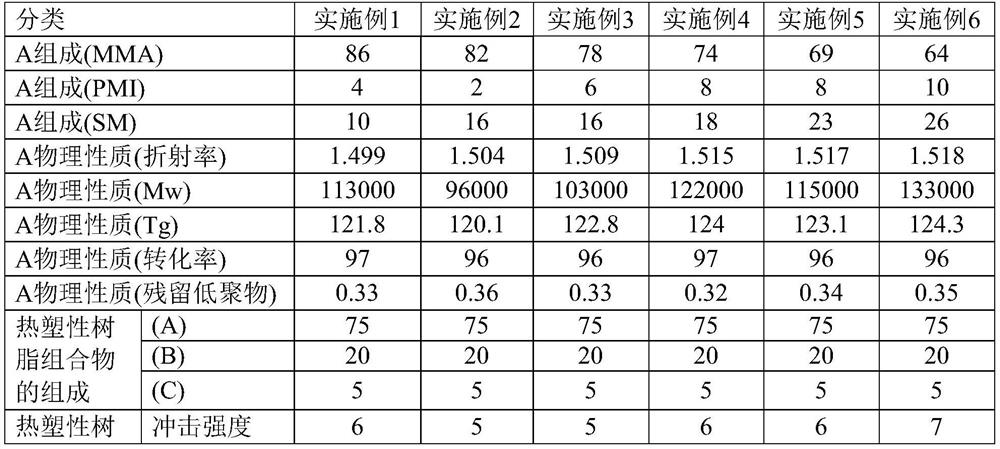

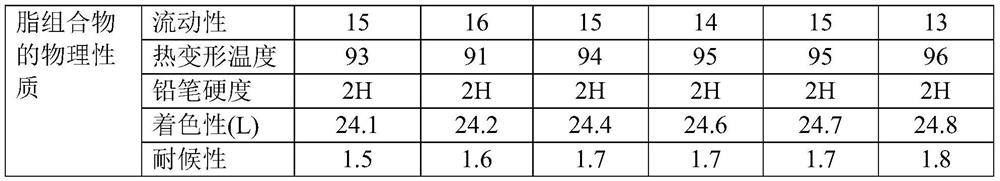

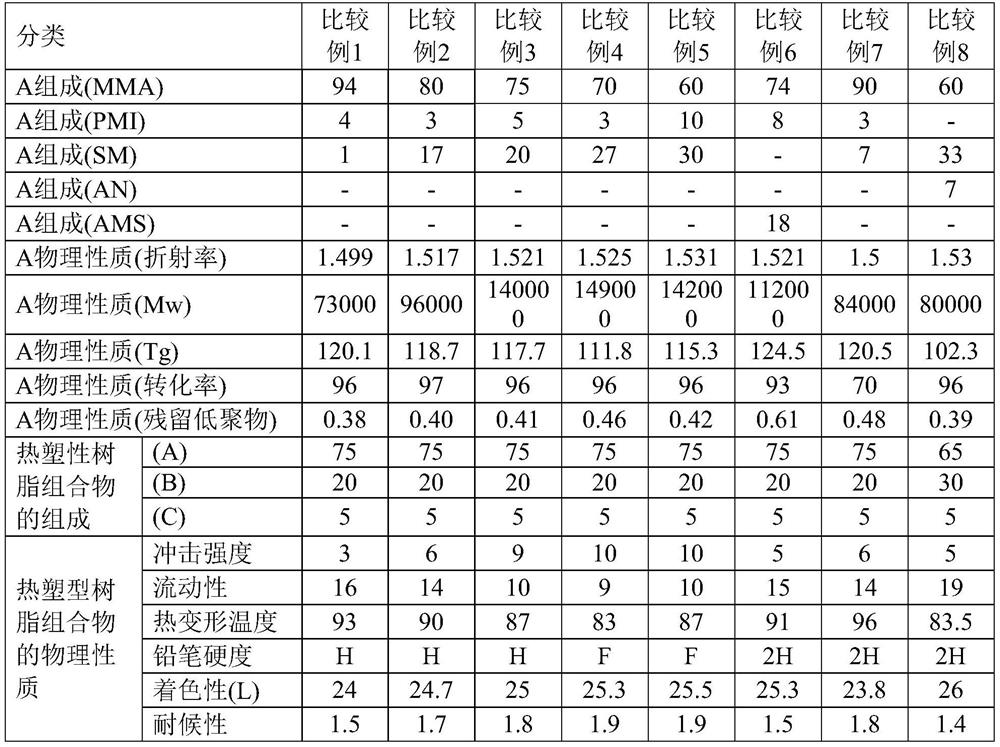

[0171] Samples were prepared in the same manner as in Example 1, except that the components and contents shown in Table 1 below were used in preparing the styrene-based copolymer (A).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com