Composite caproic acid bacterium liquid for producing strength flavor type Baijiu and preparation method of composite caproic acid bacterium liquid

A technology of Luzhou-flavor liquor and caproic acid bacteria, which is applied in the field of compound caproic acid bacterial liquid and its preparation, can solve the problems of single bacterial group structure, inability to retain microbial diversity, separation, cultivation and preservation of pure caproic acid bacterial liquid and other problems, to achieve the effect of rich flora, increased content, and obvious aroma in the cellar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

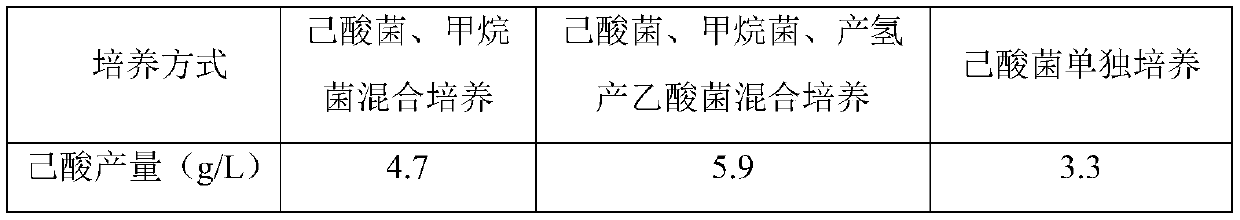

Method used

Image

Examples

Embodiment 1

[0026] 1. Preparation of caproic acid-producing bacteria enrichment solution utilizing galactitol:

[0027] 1.1 Preparation of Medium I

[0028] Each 100 ml of water contains the following substances: galactitol 1.0g, yeast extract 0.3g, tryptone 0.1g, L-asparagine 0.04g, L-cysteine hydrochloride 0.02g, resazurin 0.0001 g, KH 2 PO 4 0.2g, K 2 HPO 4 ·3H 2 O0.2g, MgSO 4 ·7H 2 O 0.008g, MnSO 4 ·H 2 O 0.008g, FeSO 4 ·7H 2 O 0.0013g, NaCl 0.008g, pH 6.5-7.0.

[0029] 1.2 Preparation of caproic acid-producing bacteria enrichment solution utilizing galactitol

[0030] Pass the galactitol-using caproic acid-producing bacteria enrichment medium into nitrogen deoxygenation, sterilize at 121°C for 20 minutes, cool to 40°C, take high-quality pit mud, add 2 times the amount of sterile water according to the weight-volume ratio, and stir evenly , feed nitrogen to deoxygenate, inoculate in the galactitol-producing caproic acid bacteria enrichment medium by 10% volume ratio, c...

Embodiment 2

[0055] 1. Preparation of caproic acid-producing bacteria enrichment solution utilizing galactitol:

[0056] 1.1 Preparation of Medium I

[0057] Every 100 ml of water contains the following substances: galactitol 2.0g, yeast extract 0.4g, tryptone 0.2g, L-asparagine 0.05g, L-cysteine hydrochloride 0.02g, resazurin 0.0003 g, KH 2 PO 4 0.3g, K 2 HPO 4 ·3H 2 O0.3g, MgSO 4 ·7H 2 O 0.01g, MnSO 4 ·H 2 O 0.01g, FeSO 4 ·7H 2 O 0.0015g, NaCl 0.1g, pH6.5-7.0.

[0058] 1.2 Preparation of caproic acid-producing bacteria enrichment solution utilizing galactitol

[0059] Pass the galactitol-using caproic acid-producing bacteria enrichment medium into nitrogen deoxygenation, sterilize at 121°C for 20 minutes, cool to 40°C, take high-quality pit mud, add 2 times the amount of sterile water according to the weight-volume ratio, and stir evenly , feed nitrogen to deoxygenate, inoculate in the galactitol-producing caproic acid bacteria enrichment medium by 12% volume ratio, culti...

Embodiment 3

[0084] This example uses the various bacterial enrichment solutions prepared in Example 2, but when preparing the compound caproic acid bacterial solution, the ratio used is: 6:4:3:3:4, and other implementation processes are the same as in Example 2.

[0085] The total number of bacteria in the compound caproic acid bacteria solution made in this embodiment is 6×10 10 pc / mL, with caproic acid-based compound aroma, spray it evenly to the cell wall and bottom to maintain the cellar pool, compared with the traditional bacterial solution to maintain the cellar pool, the content of caproic acid increased by 0.28g / L , the ethyl caproate content increased by 0.37g / L, and the premium wine rate increased by 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com