Saccharomyces cerevisiae strain with high yield of flavor ethyl ester and construction method of saccharomyces cerevisiae strain

A strain of Saccharomyces cerevisiae, the technology of Saccharomyces cerevisiae, applied in the field of bioengineering, can solve the problem of low ester production capacity of Saccharomyces cerevisiae

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Construction of high-yield flavor ethyl ester Saccharomyces cerevisiae genetically engineered strain

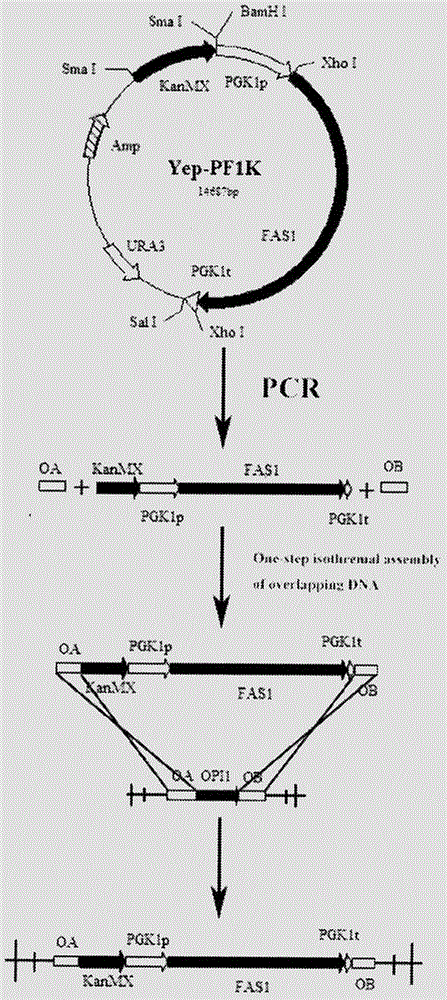

[0030] (1) Construction of genetic engineering strains

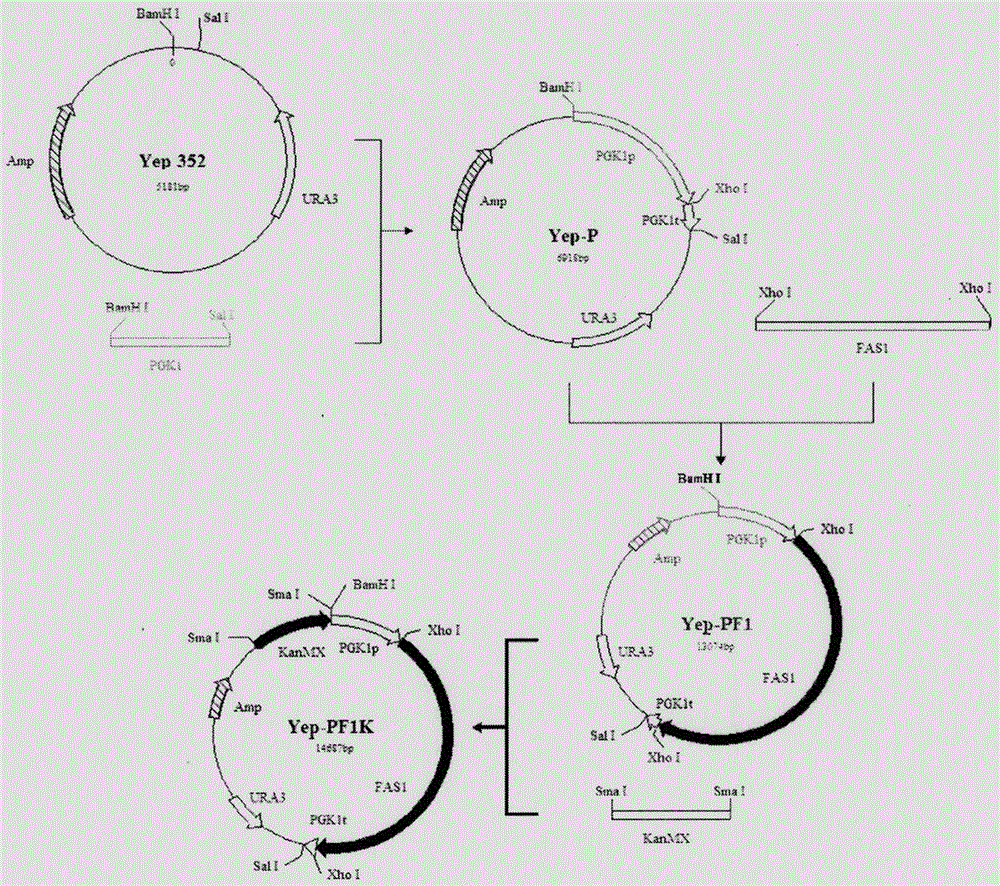

[0031] 1) Construction of Yep-PF1K plasmid

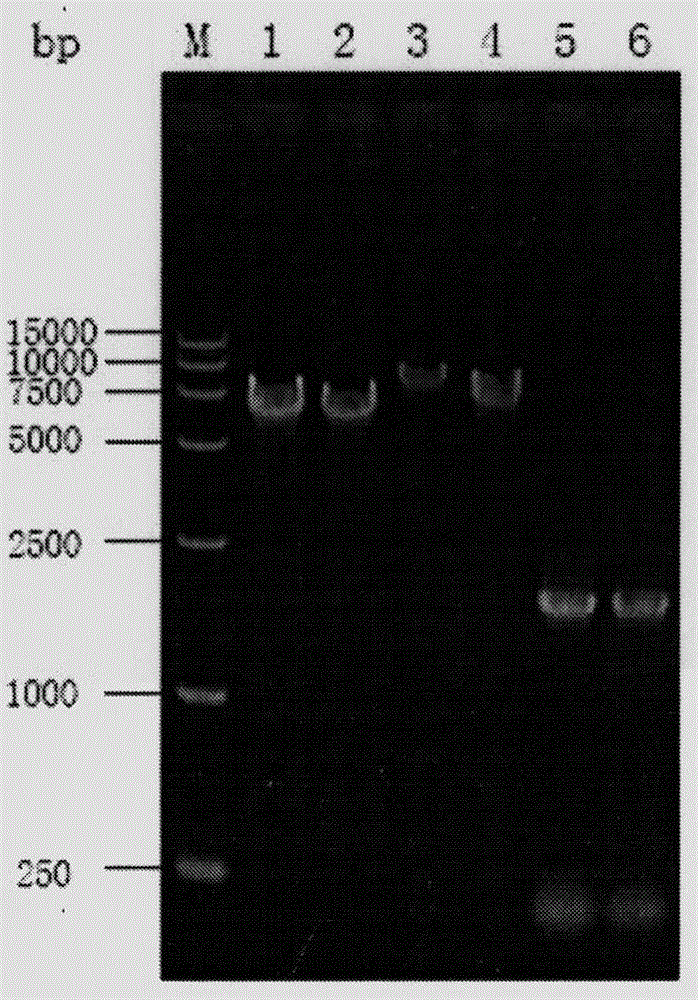

[0032] Use Yep352 as the base plasmid to construct the recombinant plasmid Yep-PF1K, the construction process is as follows figure 1 As shown, the strong promoter PGK1 was ligated into the Yep352 plasmid by BamHI / salI double enzyme digestion to obtain the plasmid Yep-P; the FAS1 gene was obtained by PCR amplification using the haploid α5 of AY15 as a template, and the Infusion ligase was used to pass the XhoI single enzyme Cut between the promoter PGK1p and the terminator PGK1t inserted on the Yep-P plasmid to obtain the plasmid Yep-PF1; use pUG6 as a template to PCR amplify the 1613bp KanMX gene, and use SmaI to single-digest the plasmid Yep-PF1 and the fragment respectively KanMX was ligated with SolutionI ligase to form the recombinant plasmid Yep-PF...

Embodiment 2

[0044] Embodiment 2: Fermentation experiment of simulated corn raw material liquid liquor

[0045] Fermentation process route:

[0046] Corn flour→soaking→liquefaction→saccharification→cooling→inoculation→fermentation→steaming wine→measurement index

[0047] Process conditions: soaking conditions: 60-70°C, immersion for 20 minutes; liquefaction conditions: 85-90°C, add high-temperature-resistant α-amylase, liquefy for 90 minutes; saccharification conditions: 55-60°C, add glucoamylase, and saccharify for 20 minutes Fermentation conditions: 30°C, 5 days. When steaming wine, take 100mL mash, add 100mL water, and steam 100mL wine sample.

[0048] Ingredients: corn flour: 60g; add water 130mL; high temperature resistant α-amylase: 30μL; glucoamylase: 90μL; acid protease: 1.2mL; nutrient salt: 1mL;

[0049] According to the above-mentioned simulation process, the recombinant strain α5-FAS1 of Saccharomyces cerevisiae and the starting strain α5 were respectively subjected to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com