Yellow rice wine jar storage method and storage apparatus thereof

A technology for tank storage and rice wine, which is applied in the field of rice wine brewing, can solve the problems of high loss, occupying a large warehouse area, and high labor intensity, and achieve the effects of avoiding changes in taste, realizing mechanized production, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

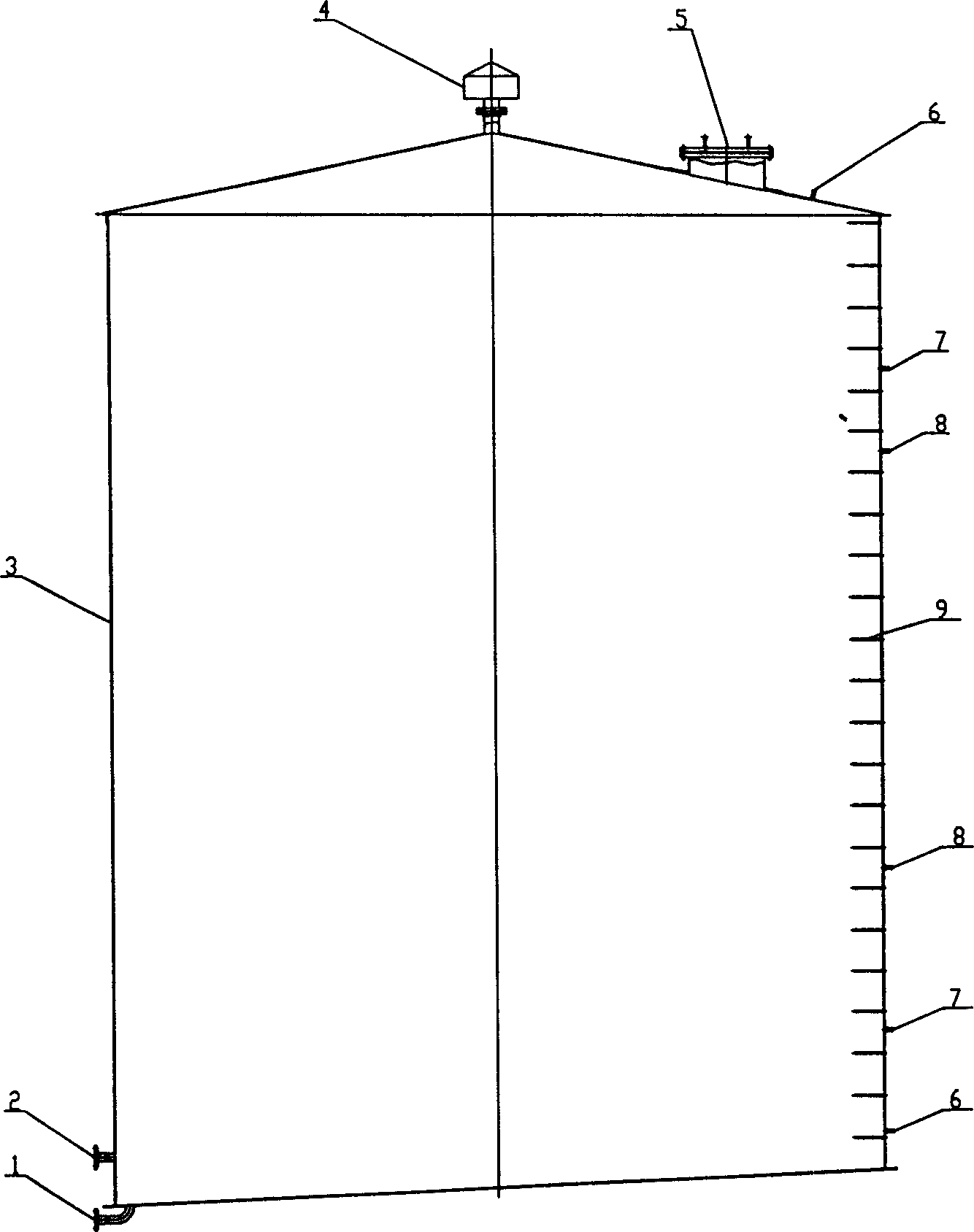

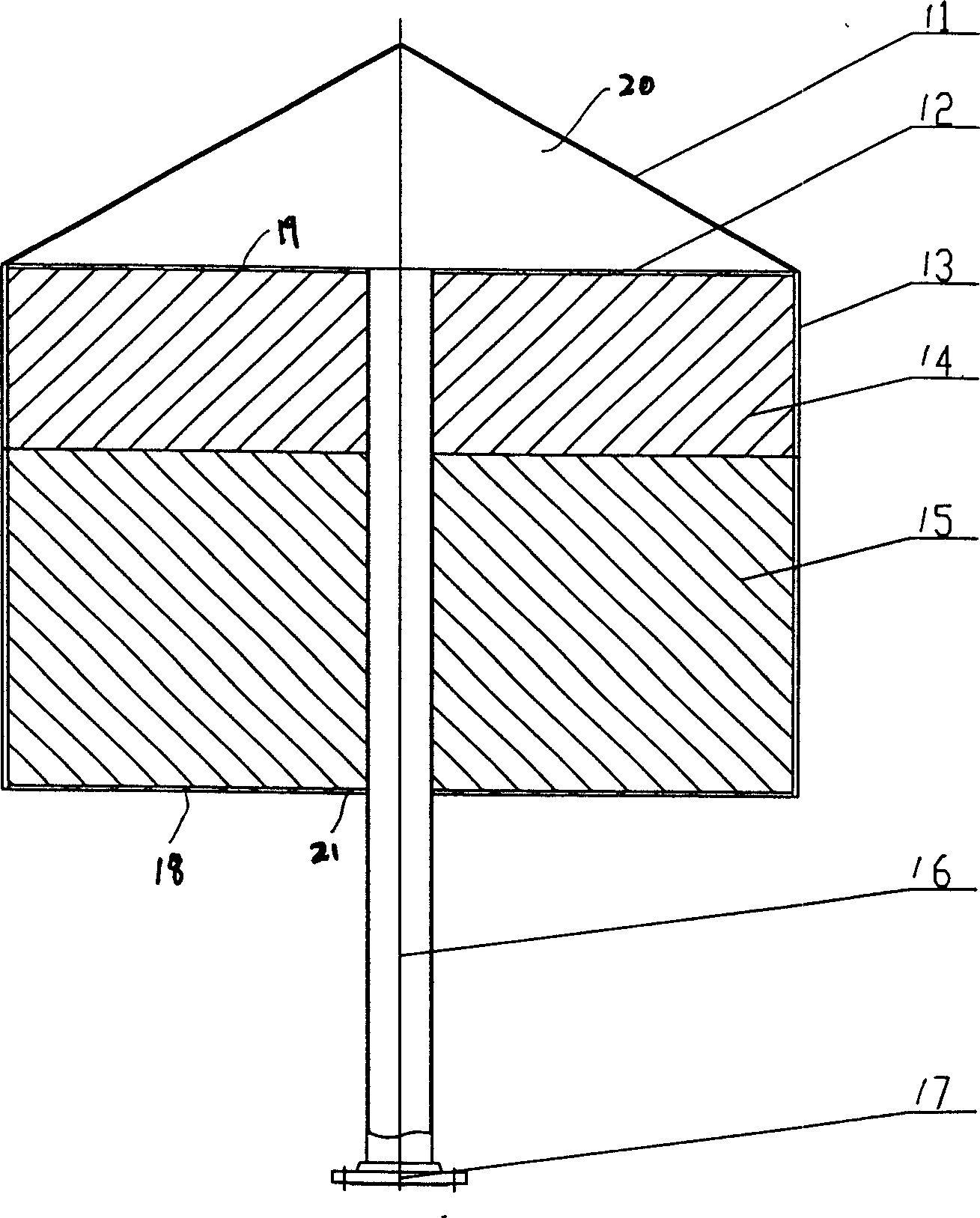

[0014] The treatment process of the present invention is as follows:

[0015] a. Deal with the large tank container: first clean the large tank 3 with clean water, and then sterilize it as usual before sealing; wash with clean water during cleaning, after cleaning, seal and sterilize the large tank to remove the Bacteria are completely eliminated. When sealing, close the inlet and outlet 2 of the big tank 3 to ensure that it is in a sealed state.

[0016] b. Sake treatment: After sterilizing the brewed sake at 80-85°C, place it in a buffer container to keep it warm for 20-30 minutes, and then cool to room temperature. The brewed sake should also be sterilized, and the sake can usually be heated. At 80-85°C, kill other bacteria in the sake. After sterilization, slowly pour the sake into a transitional container, that is, a buffer container. After about 20-30 minutes, it is cooled to room temperature by a cooler. If the wine enters the large tank at a relatively high temperature, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com