Method for curing after opening of thick white liquor pit

The technology of a strong-flavor liquor and a cellar is applied in the field of winemaking, which can solve the problems of long vacant time in cellars, adverse effects on the reproduction and metabolism of cellar mud functional microorganisms, unfavorable long-term use, etc. The effect of wine fermentation and reduction of water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

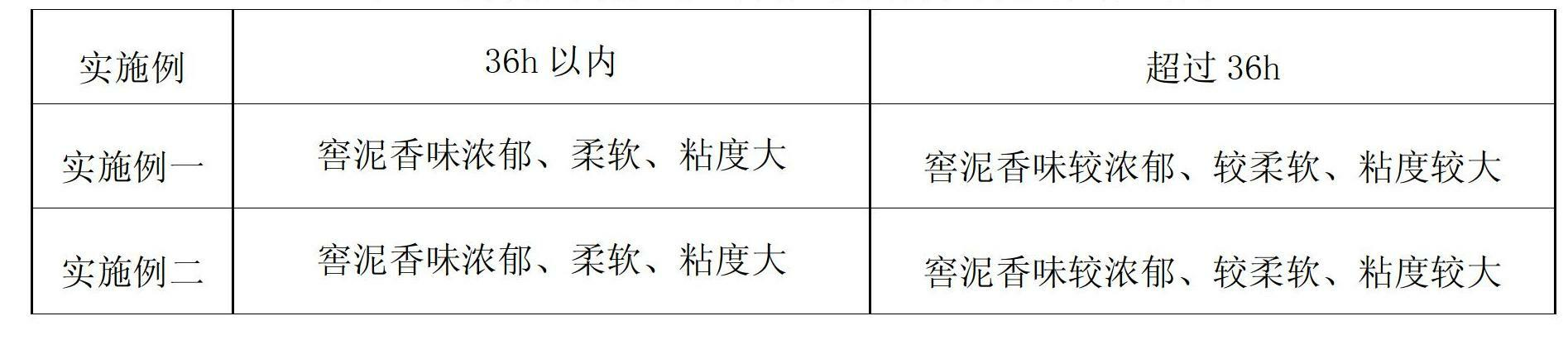

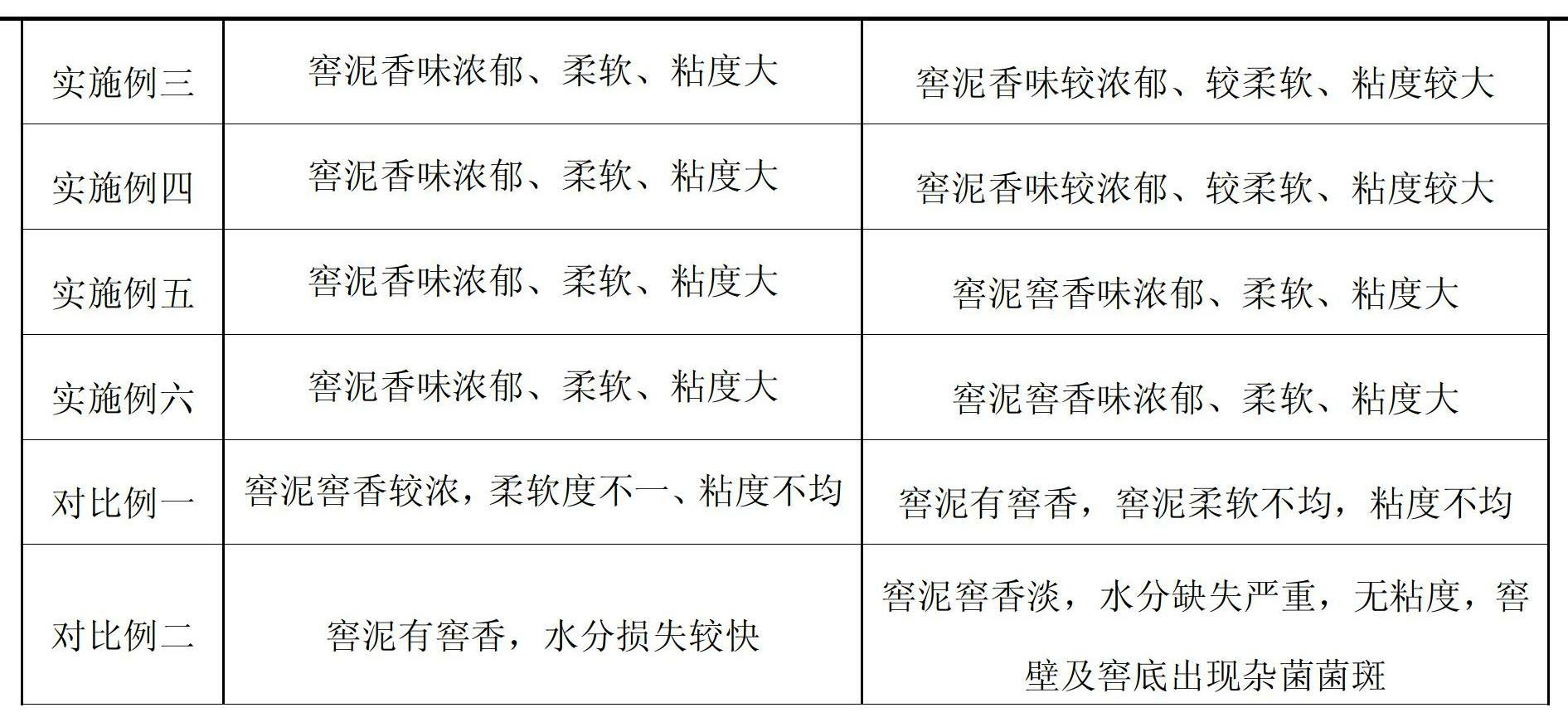

[0040] Example 1 Maintenance of cellar pools with the method of the present invention (ground temperature 33°C)

[0041] a. After the cellar is opened, cover the cellar with plastic film in time;

[0042]b. The opening time of the cellar is within 36 hours, and the cell wall and bottom of the cellar are evenly splashed with 30°C tail water every 5 hours, of which the tail water is 2kg / m 2 ;

[0043] c. When the cellar is opened for more than 36 hours, the cell wall and bottom of the cellar are evenly sprinkled with 30°C tail water every 3 hours, and the tail water containing koji powder is sprinkled at intervals of 11 hours. Among them, the tail water is 4kg / m 2 , Quyao 0.05kg / m 2 , the koji is a medium-high temperature koji for the production of commercially available Luzhou-flavor liquor;

[0044] d. One hour before the cellar and the mother's waste enter the cellar, the tail water containing medium and high temperature koji medicine is splashed for the last time, of whi...

Embodiment 2

[0045] Example 2 Use the method of the present invention to maintain the cellar (ground temperature 33°C)

[0046] a. After the cellar is opened, cover the cellar with colored cloth in time;

[0047] b. The opening time of the cellar is within 36 hours, and the cell wall and bottom of the cellar are evenly sprayed with 30°C tail water every 4 hours, of which the tail water is 2kg / m 2 ;

[0048] c. When the cellar is opened for more than 36 hours, the cell wall and bottom of the cellar are evenly sprinkled with 30°C tail water every 4 hours, and the tail water containing koji powder is sprinkled at intervals of 11 hours. Among them, the tail water is 3kg / m 2 , Quyao 0.15kg / m 2 , the koji is a medium-high temperature koji for the production of commercially available Luzhou-flavor liquor;

[0049] d. 1 hour before the cellar’s mother’s waste enters the cellar, sprinkle the tail water for the last time, and at the same time directly sprinkle the fine powder of koji medicine,...

Embodiment 3

[0050] Example 3 Use the method of the present invention to maintain the cellar (ground temperature 20°C)

[0051] a. After the cellar is opened, cover the cellar with plastic film in time;

[0052] b. The opening time of the cellar is within 36 hours, and the cell wall and bottom of the cellar are evenly sprayed with 27°C tail water every 5 hours, of which the tail water is 2kg / m 2 ;

[0053] c. When the cellar is opened for more than 36 hours, the cell wall and bottom of the cellar are evenly sprayed with 27°C tail water every 4.5 hours, and the tail water containing koji powder is sprinkled at intervals of 9 hours. Among them, the tail water is 3kg / m 2 , Quyao 0.15kg / m 2 , the koji is a medium-high temperature koji for the production of commercially available Luzhou-flavor liquor;

[0054] d. One hour before the cellar pits are put into the cellar, the tail water containing medium and high temperature koji medicine is splashed for the last time, of which the tail water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com