Mobile vacuum degree inspection and maintenance vehicle

A technology for repairing vehicles and vacuum degree, which is applied in liquid tightness measurement, vacuum gauge, motor vehicles, etc. by using liquid/vacuum degree. Avoid pipeline link compensation, avoid mutual collision, and easily convert effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

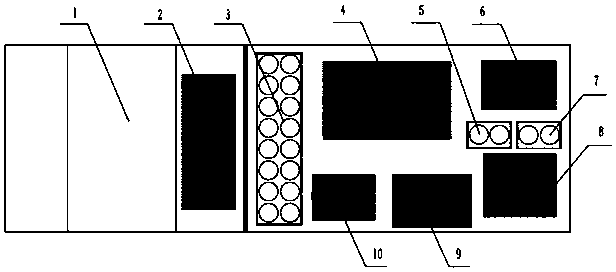

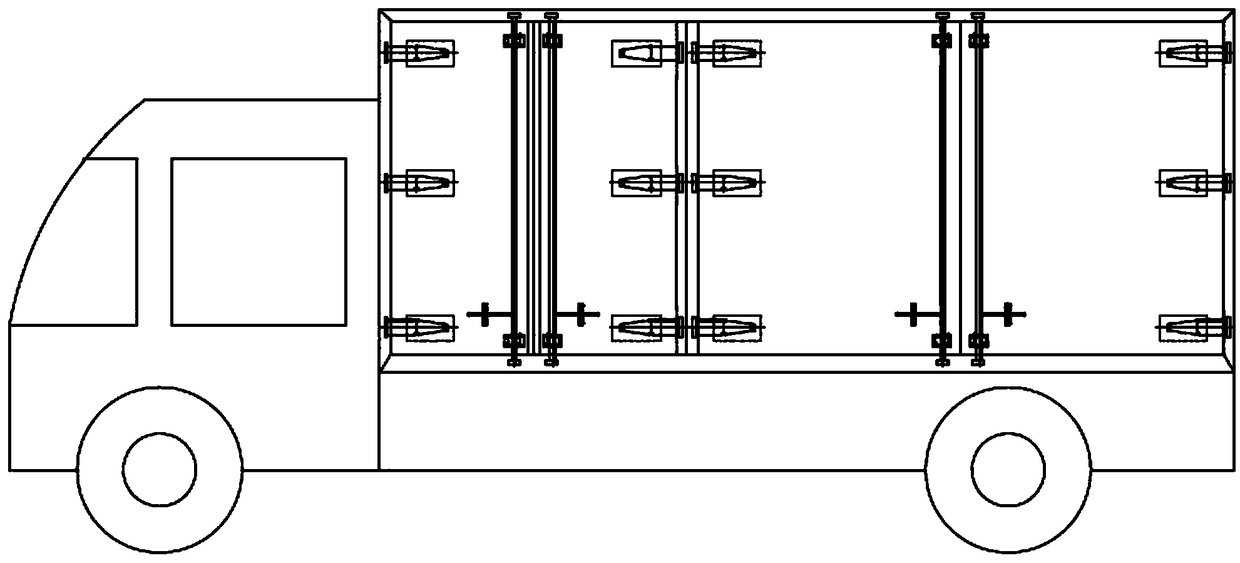

[0013] The mobile vacuum detection and maintenance integrated vehicle mainly includes container truck 1, diesel generator 2, nitrogen gas storage device 3, vacuum unit 4, argon gas storage device 5, helium simple leak detector 6, helium gas storage device 7, Argon arc welding machine 8, accessory storage cabinet 9, electrical control system 10, etc.

[0014] The diesel generator 2 can generate electricity by itself to meet the power demand of the corresponding components of the inspection vehicle;

[0015] High-pressure nitrogen is housed in the nitrogen gas storage device 3, which is used for natural gas purging and replacement of cryogenic equipment;

[0016] The vacuum unit 4 vacuumizes the equipment that has been reduced in vacuum and repaired to restore its low-temperature storage performance.

[0017] The argon gas storage device 5 is equipped with argon gas, which can be used when the argon arc welding machine repairs product defects;

[0018] The simple helium leak d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com