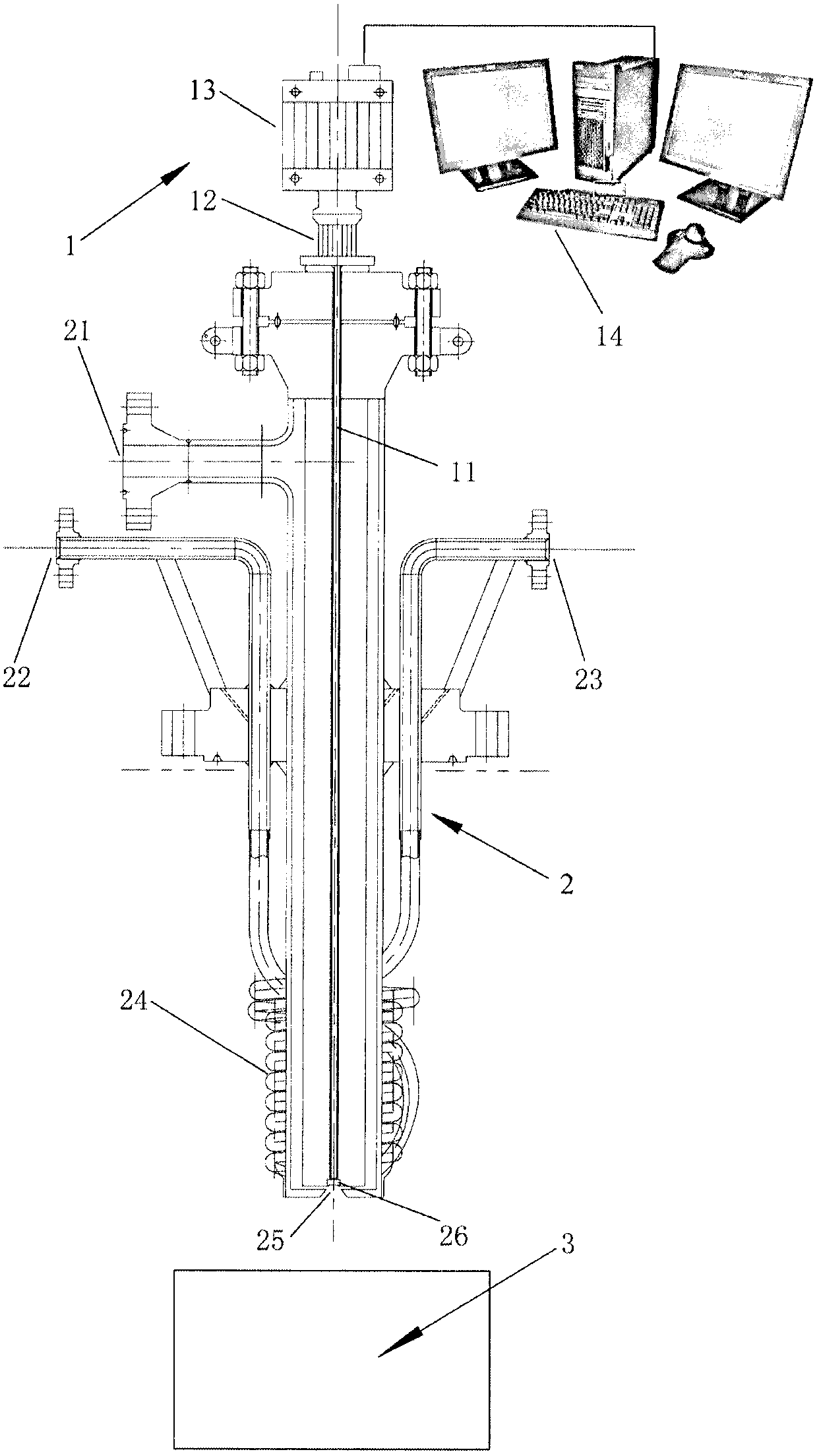

Detection device and method for three-dimensional temperature field in combustion chamber of single-CCD imaging system

A technology of three-dimensional temperature and imaging system, which can be applied in measurement devices, radiation pyrometry, optical radiation measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Based on the thermal state test platform of the multi-nozzle opposed coal-water slurry gasifier, the three-dimensional temperature field in the multi-nozzle opposed gasifier is restored by using the device and method for detecting the three-dimensional temperature field in the furnace of the single CCD imaging system of the present invention.

[0065] Coal-water slurry is used as the gasification medium, and the four nozzles are horizontally opposed to each other at 90°. The inner channel of the dual-channel nozzle is metered by the screw pump to transport the coal-water slurry into the furnace, and the annular gap delivers oxygen to realize the atomization of the fuel. Four channels of oxygen, The coal water slurry is violently impacted and burned in the furnace, and undergoes gasification reaction to generate synthesis gas. The four-nozzle coal-water slurry flow rate is 11.50kg / h each, and the oxygen flow rate range is 5.70Nm 3 / h~6.30Nm 3 / h, control the oxygen-carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com