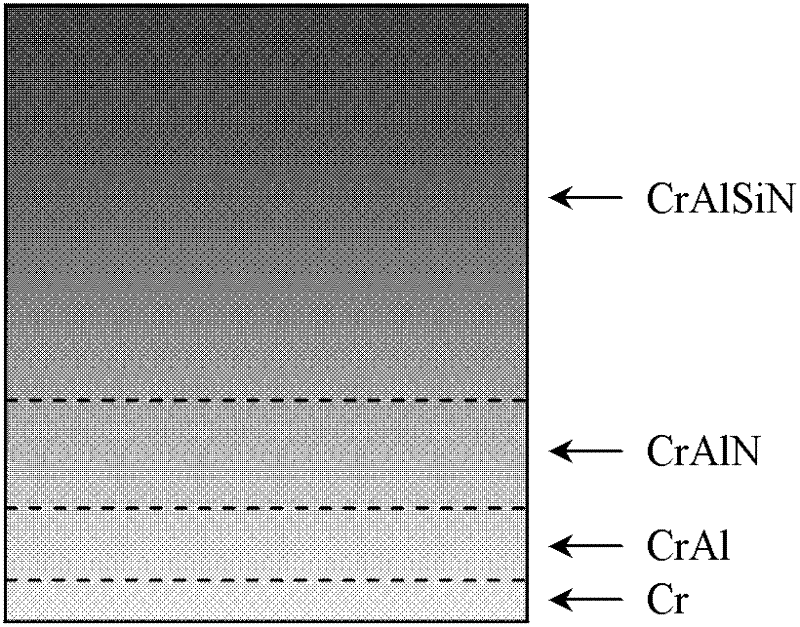

Technology for preparing nuclear fission reactor fuel clad surface CrAlSiN gradient coating

A gradient coating and fuel cladding technology, applied in metal material coating process, coating, fuel elements, etc., can solve the problems of poor high temperature corrosion resistance and achieve good toughness, thermal shock resistance, and excellent mechanical properties , the effect of excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation process of the CrAlSiN gradient coating of the present invention is carried out sequentially according to the aforementioned process steps and process conditions.

[0037] Depositing a CrAlSiN gradient coating on the surface of the 316Ti stainless steel substrate used for supercritical water-cooled reactor fuel cladding includes the following process steps:

[0038] (1) Surface polishing and cleaning of substrate samples

[0039] First, the surface of the substrate sample is ground and polished with 300-1200 mesh water sandpaper in sequence; then, the degreasing agent is cleaned in an ultrasonic vessel, and the degreasing agent is composed of sodium carbonate 160g / L, sodium citrate 45g / L, active agent 5g / L, sodium phosphate 50g / L; then carry out pickling and deionized water rinsing, after pickling and rinsing, use N 2 air to dry the substrate sample; finally, place the substrate sample in a vacuum chamber for plasma bias backsplash cleaning, and the pr...

Embodiment 2

[0057] The CrAlSiN gradient coating was prepared using the same process steps, process conditions and process parameters as in Example 1; because the coating performance is affected by the properties of the substrate, sublayer thickness, composition gradient, etc., the difference from Example 1 is Example 2 The substrate used is a 1.4970 austenitic stainless steel substrate. In this embodiment, a CrAlSiN gradient coating is deposited on the surface of the 1.4970 steel substrate.

[0058] The experimental results of Example 2 are: the thicknesses of the Cr, CrAl and CrAlN sub-layer coatings are 120 nm, 220 nm and 300 nm respectively; the thickness of the CrAlSiN gradient coating is 3.0 μm.

[0059] Except above-mentioned, other processing parameters are all identical with embodiment 1. Adopt the same coating performance testing method as in Example 1. The results show that the CrAlSiN gradient coating has a hardness of 39GPa, an interface adhesion with the substrate of 36N, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness value | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com