Silicon PU court and manufacturing method thereof

A court and basic technology, which is applied in the field of silicon PU courts and its production, can solve the problems of unsightly color difference in the repaired places, long maintenance period of the foundation, and difficulty in repairing, etc., and achieve the effects of preventing air bubbles, improving adhesion, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

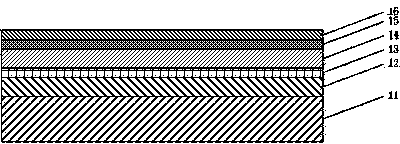

Image

Examples

Embodiment 1

[0036] (1) Basic treatment:

[0037] a. Grinding seam: Grind the base surface on both sides of the temperature joint with a width of 40-50 mm to a bevel depth of 3 mm, so that the surface of the temperature joint becomes a "V" shape, and the width of each side is 40-50 mm to improve the gap between the caulking glue and the base surface The bonding area increases its bonding force. The depth of 3mm is to ensure the thickness of the caulking glue without occupying the position of the elastic layer, to ensure the overall good cushioning, so that the thermal expansion and contraction of the foundation will not affect the surface of the silicon PU.

[0038] b. Pickling: Wet the foundation with clean water (to prevent dilute hydrochloric acid from penetrating into the foundation), evenly sprinkle and wash the base surface with dilute hydrochloric acid with a concentration of about 8%, and then rinse it with clean water, generally rinse twice, and ask for after washing and drying T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com