Glue spreading device and glue spreading equipment

A gluing device and gluing technology, applied in the direction of electrode manufacturing, etc., can solve problems affecting battery quality, air bubbles, suction cups and pole pieces are not completely parallel, and achieve the effect of avoiding air bubbles and wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

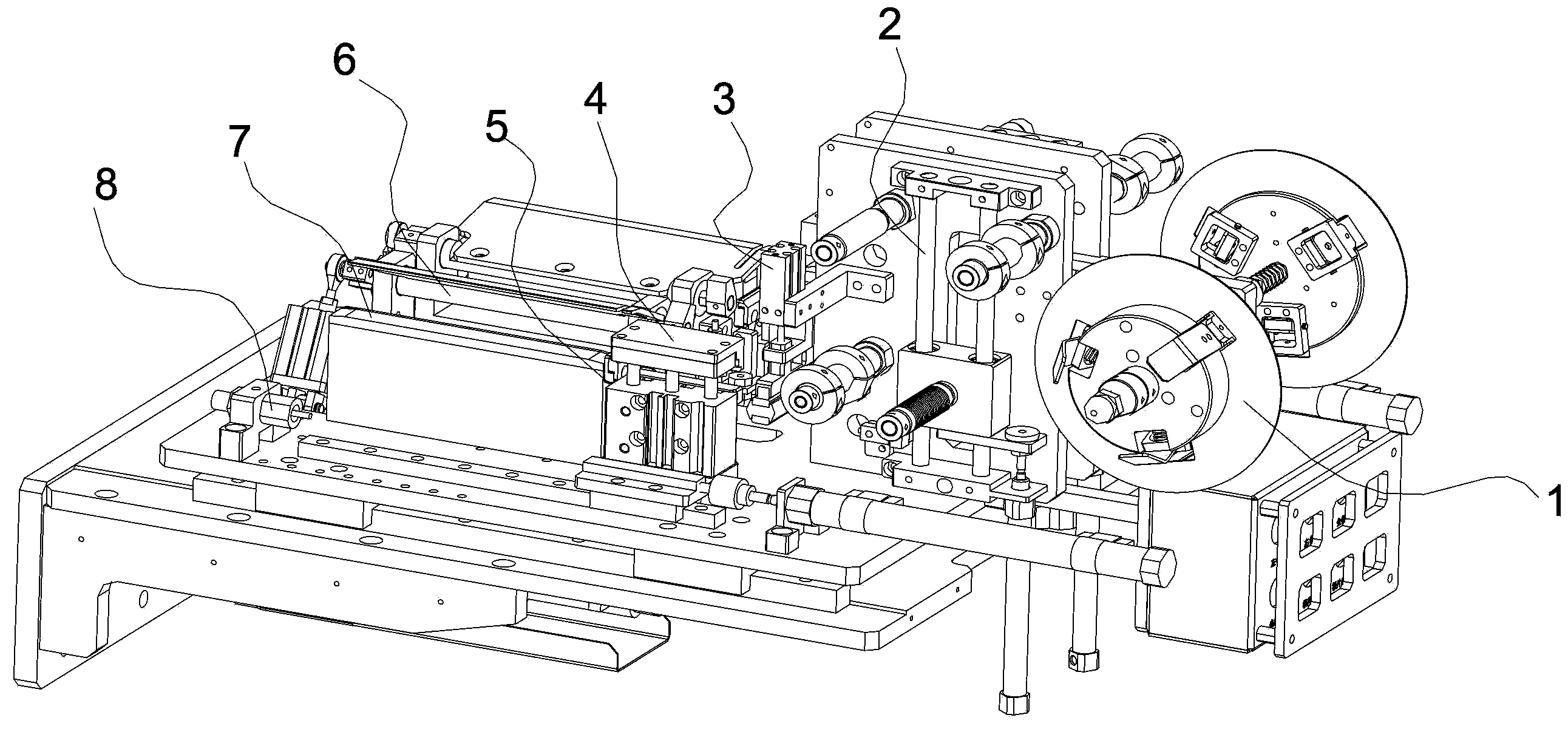

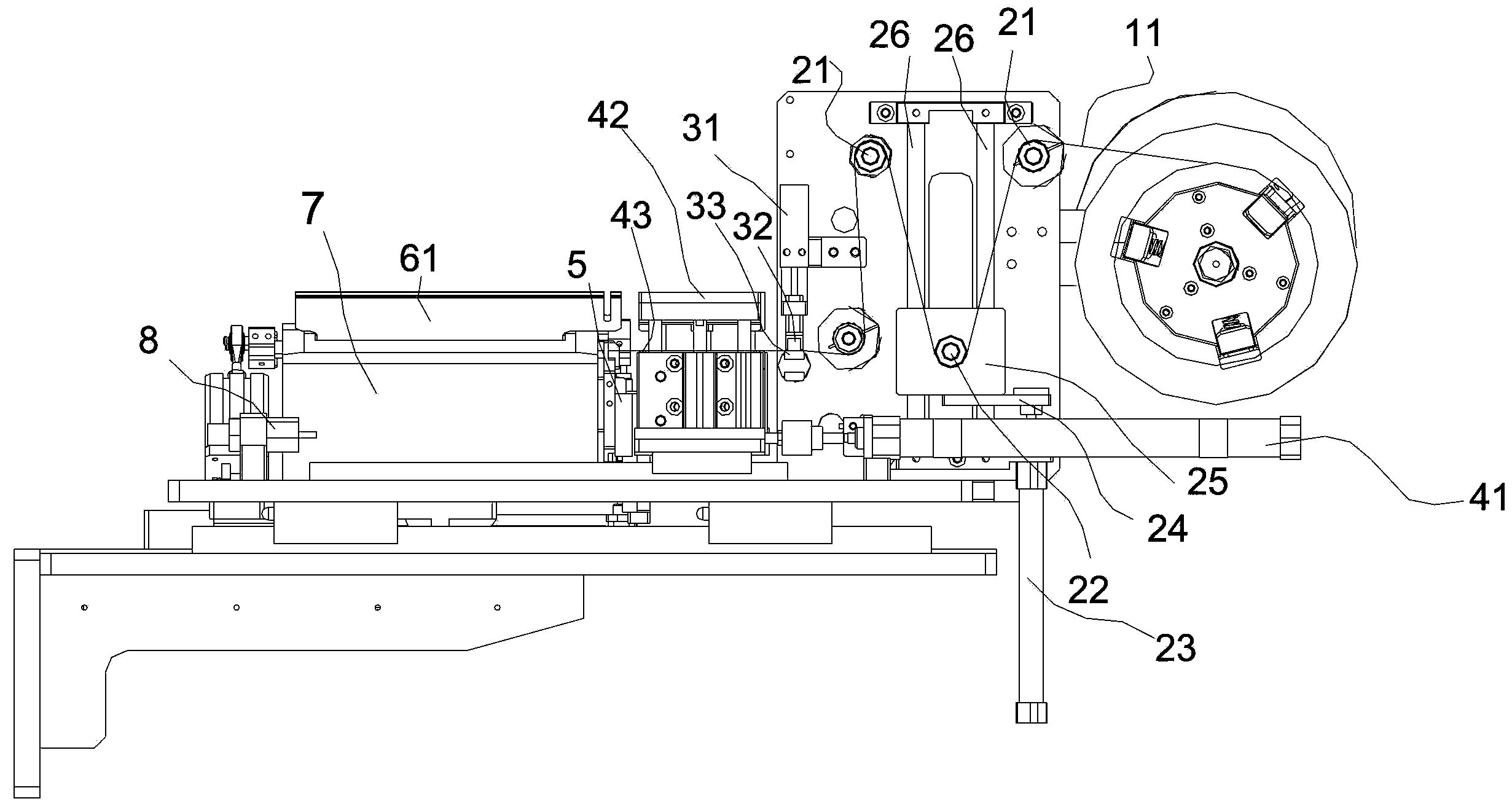

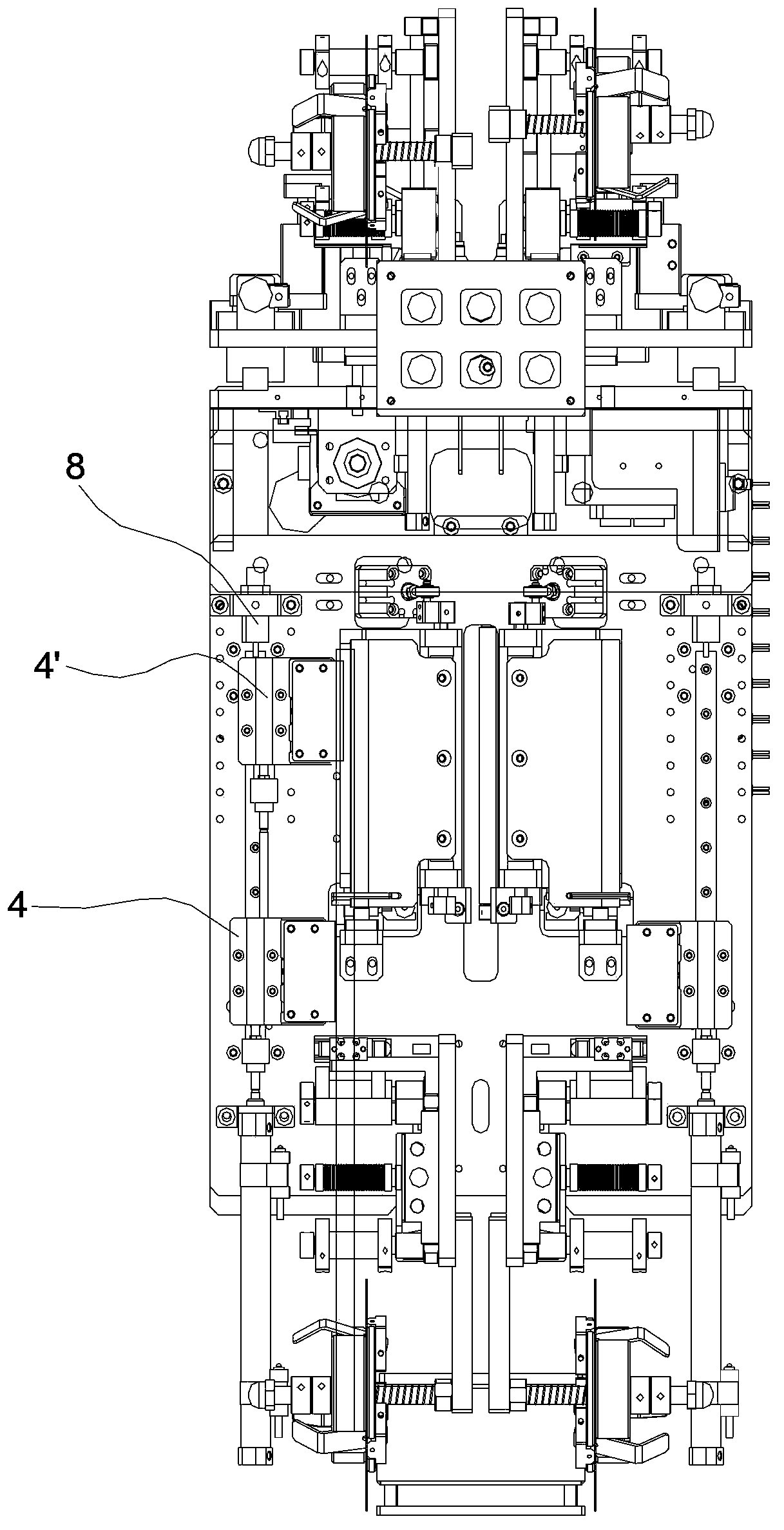

[0036] The gluing equipment provided in this embodiment includes a gluing device and a gluing preparation device.

[0037] The gluing device includes a machine frame, gluing power components and pressing belt parts. The frame is used to provide support for the device, and the glue-applying power assembly is installed on the frame for outputting reciprocating motion. The pressing tape part is connected with the gluing power assembly, and the gluing power assembly drives the pressing tape part at least at the pressing tape position where the pressing tape part is in contact with the tape to be pasted and the tape to be pasted is pressed on the pole piece and can be used The pressing tape part is separated from the pole piece so that the glue preparation device repositions the adhesive tape to be pasted to the initial position of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com