Back film of solar cell and preparing technique thereof

A solar cell and production process technology, which is applied to circuits, photovoltaic power generation, electrical components, etc., can solve problems such as insufficient bonding strength between film layers, bubble retention, and single structure of the back film of solar panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

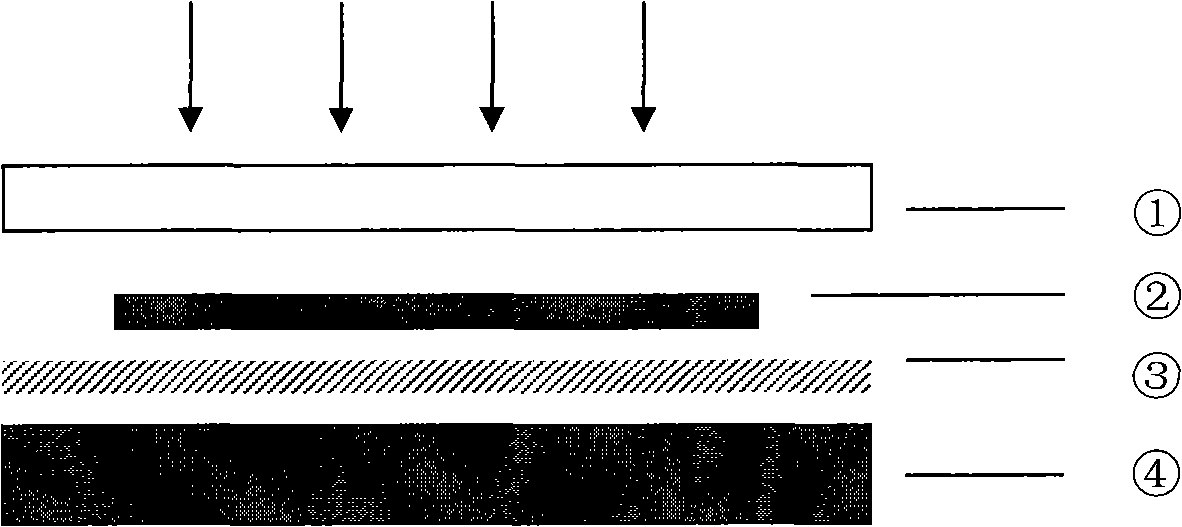

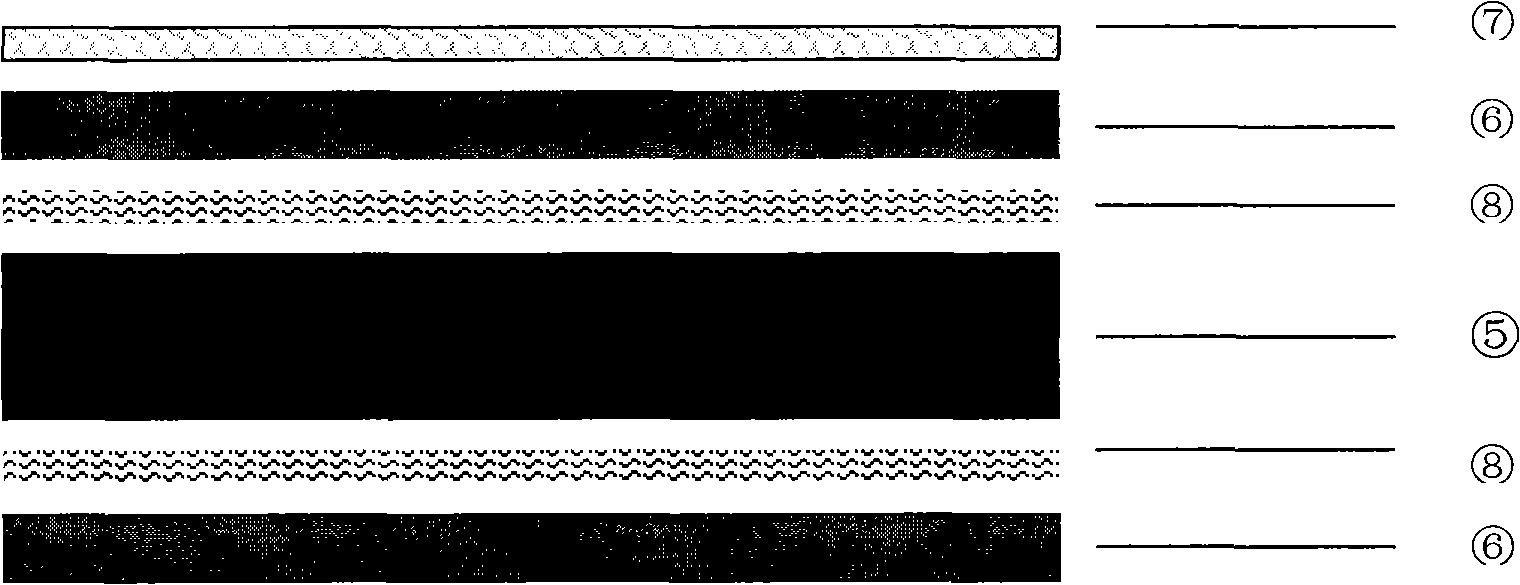

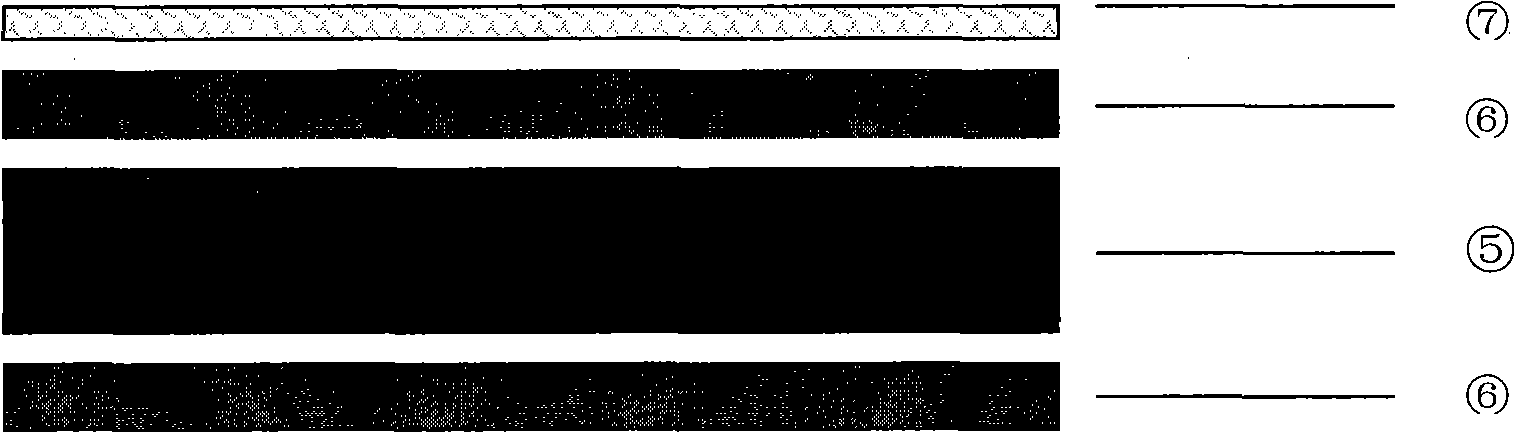

Method used

Image

Examples

Embodiment 1

[0077] Treat the surface of the PET film with a thickness of 150 μm with a surfactant, then wash it with deionized water to remove the oil on the surface of the film, and dry it for later use.

[0078] The polycrystalline epoxy resin is melted at 80-100°C, and a layer of adhesive is coated on the treated PET surface by roller coating, and the thickness after drying at 150°C is about 2 μm.

[0079] Polyvinyl fluoride (PVF) particles, propylene glycol methyl ether, amino resin and titanium dioxide (TiO 2 ) according to the ratio of 35:30:5:30, uniformly mixed in a glass bead sand mill, and sanded for 0.5 hours to form a mixed solution with good leveling, fineness less than 25 microns and moderate viscosity, and then heated to 170 degrees Celsius , using a roller coating method to apply a layer of fluoropolymer coating on adhesive-treated PET film. After baking at a temperature of 170 degrees Celsius for 10 minutes, the solvent in the fluoropolymer coating evaporates to form a f...

Embodiment 2

[0086] Polyvinylidene fluoride (PVDF) particles, propylene glycol methyl ether, polyester resin and titanium dioxide (TiO 2 ) according to the ratio of 35:30:5:30, uniformly mixed in a glass bead sand mill, and sanded for 1 hour to form a mixed solution with good leveling, fineness less than 25 microns and moderate viscosity, and then heated to 160 degrees Celsius , A layer of PVDF coating was applied on a clean PET film (about 150 μm in thickness) by roller coating. After baking at a temperature of 150 degrees Celsius for 10 minutes, the solvent in the PVDF coating volatilizes to form a PVDF film with a thickness of about 20 μm.

[0087]If one-side coating is adopted, repeat the above PVDF coating steps, and also coat the PVDF film on the other side of the film.

[0088] A layer of polycrystalline epoxy resin with a thickness of about 1 μm was coated on the fluorine-containing coating by scraping. After drying at 150°C, a formal solar cell back film product is obtained.

...

Embodiment 3

[0091] The PET film with a thickness of 120 μm was destaticized on the surface by electric ironing, and then a layer of EVA adhesive was applied on the PET surface by brushing, and the thickness after drying at 120°C was about 2 μm.

[0092] Polytetrafluoroethylene (PTFE) particles, butyl ether acetate, amino resin, titanium dioxide (TiO 2 ) and carbon black in a ratio of 35:30:4.5:30:0.5, uniformly mixed in a glass bead sand mill, and sanded for 1 hour to form a mixed solution with good leveling, fineness less than 25 microns, and moderate viscosity, Then it was heated to 180 degrees Celsius, and a layer of PTFE coating was coated on the PET film (about 124 μm in thickness) coated with EVA glue by rolling coating. After baking at a temperature of 150 degrees Celsius for 10 minutes, the solvent in the PTFE coating evaporates to form a film with a thickness of about 20 μm.

[0093] If the single-side coating method is adopted, repeat the above-mentioned PTFE coating steps, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com