Isolating polypropylene composite material and preparation method thereof

A composite material and polypropylene technology, applied in the field of composite material preparation, can solve the problems of complex multi-layer co-extrusion process, low EVOH strength, unsuitable for popularization and use, etc., and achieve high toughness, low production cost, high gas barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 20 parts (by weight, the same below) of ethylene-vinyl alcohol copolymer and 80 parts of polypropylene into a twin-screw extruder at 180° C. for melt blending and extrusion. Test the gas barrier performance of the extrudate: the water vapor transmission rate (38, 90% RH) is 2996g·μm / (m 2 24h).

Embodiment 2

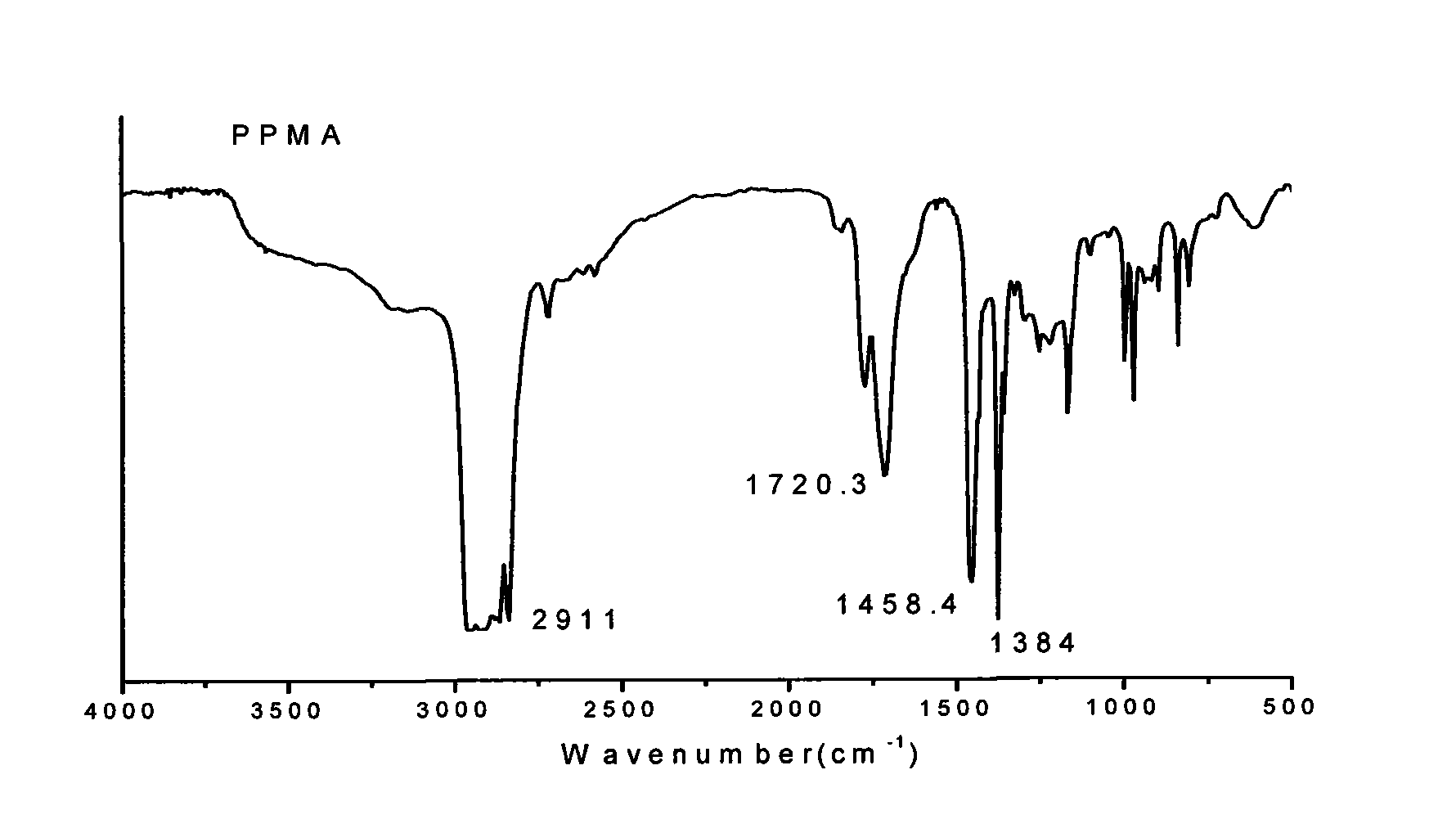

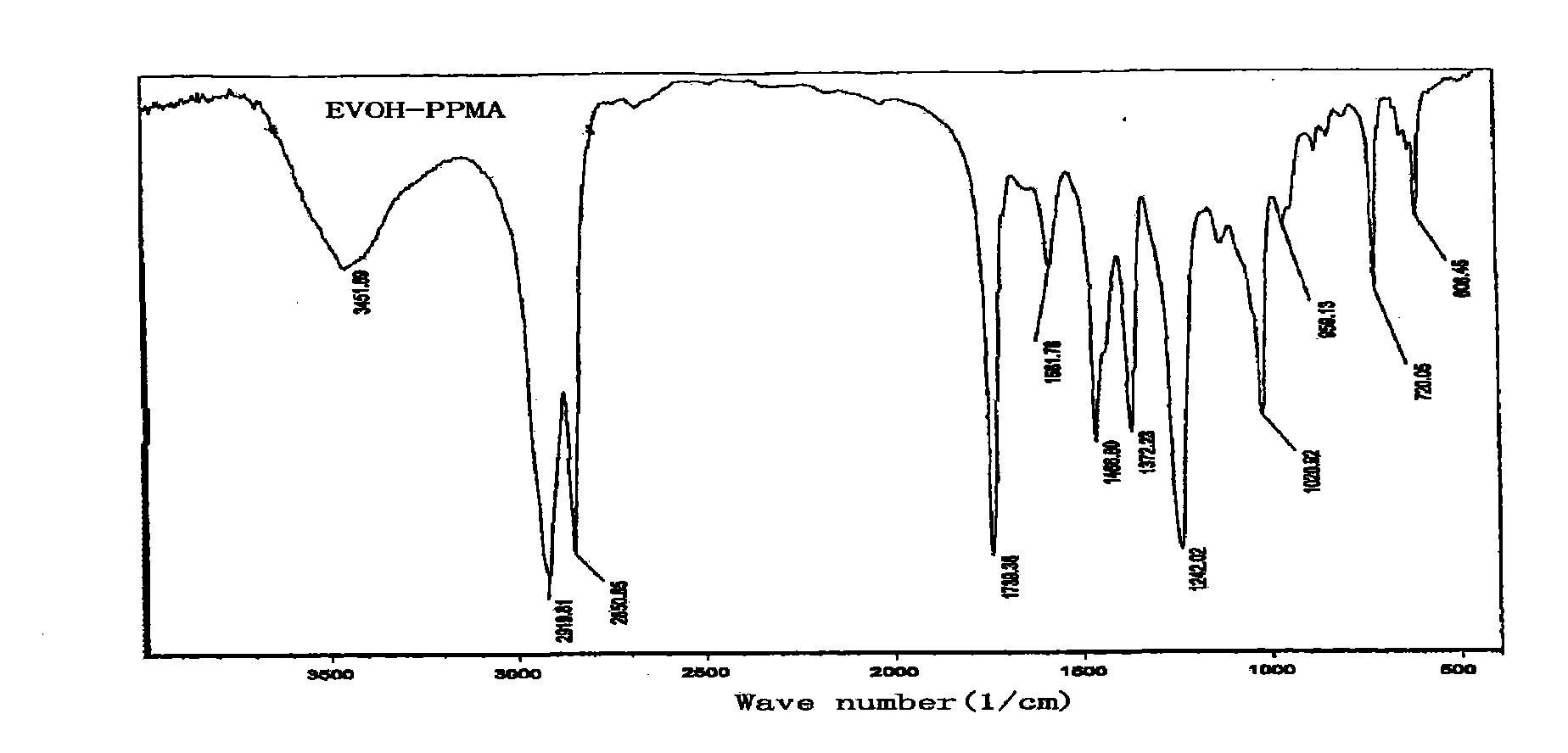

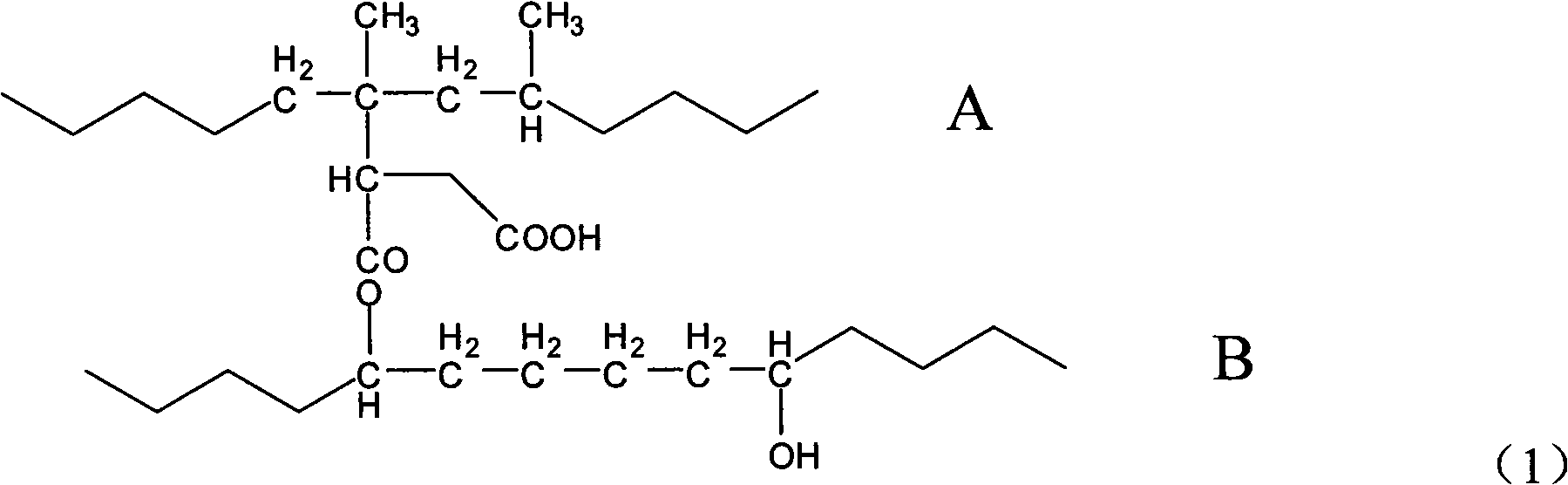

[0027] 98.8wt% of PP, 1wt% of maleic anhydride and 0.2wt% of 2,5-dimethyl-2,5-bis(t-butylperoxy)hexane were melt-grafted at 170°C to obtain PPMA ; 100 parts of PPMA and 5 parts of ethylene-vinyl alcohol copolymer are blended and extruded in a twin-screw extruder at 110°C, and the product is a compatibilizer.

[0028] Melt and knead 80 parts of polypropylene, 20 parts of ethylene-vinyl alcohol copolymer and 1 part of compatibilizer in a twin-screw mixer at 180°C to prepare a polypropylene composite material, and test its gas barrier Performance: Water vapor transmission rate (38°C, 90%RH) is 2158g·μm / (m 2 24h).

Embodiment 3

[0030] 90wt% of PP, 9.5wt% of maleic anhydride and 0.5wt% of 1,4-bis(tert-butylperoxy)dicumene were melt-grafted at 180°C to obtain PPMA; 100 parts of PPMA and 10 parts of ethylene-vinyl alcohol copolymer in a twin-screw extruder at 130°C for blending reaction and extruding, and the product is a compatibilizer.

[0031] Melt and knead 80 parts of polypropylene, 20 parts of ethylene-vinyl alcohol copolymer and 3 parts of compatibilizer in a twin-screw mixer at 190°C to prepare a polypropylene composite material, and test its gas barrier Performance: Water vapor transmission rate (38°C, 90% RH) is 2097g·μm / (m 2 24h).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com