Five-layer coextrusion transfusion medicine packing film and manufacturing method thereof

A packaging and pharmaceutical technology, applied in the directions of transportation and packaging, packaging, wrapping paper, etc., can solve the problems of difficult decomposition, low particle dissolubility, environmental hazards, etc., and achieve good softness and toughness, smooth surface, high operation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

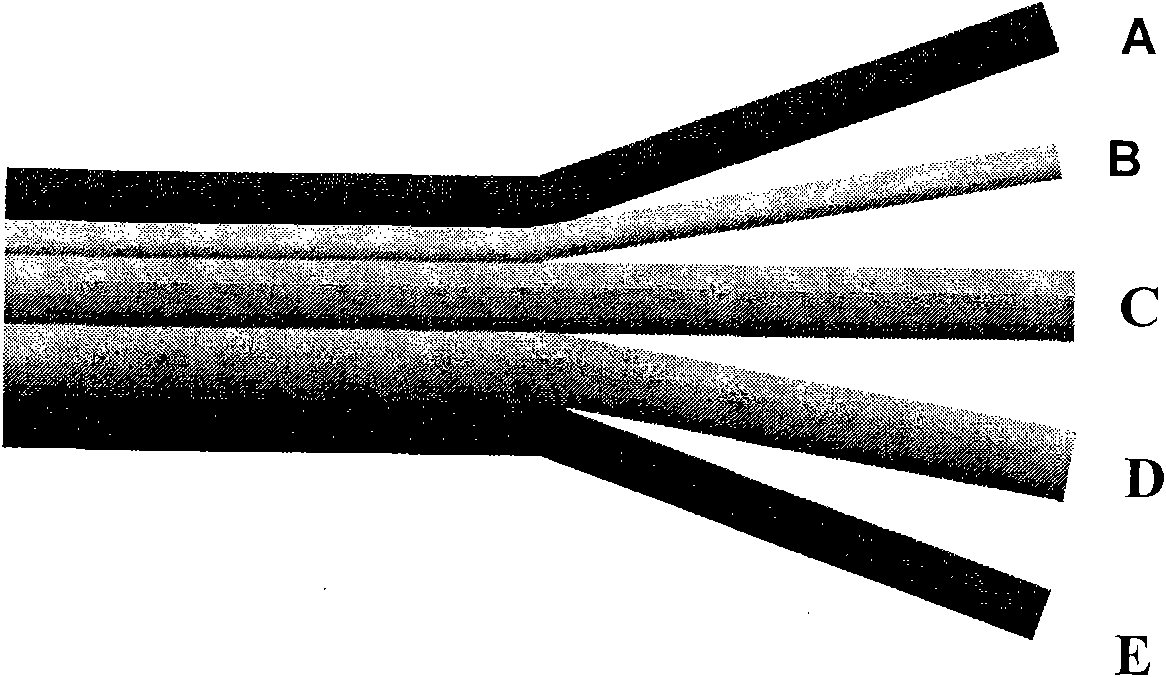

[0050] The thickness of layer A is 10 μm, and the polyester is Ecdel 9965 produced by Eastman.

[0051] The thickness of layer B is 8 μm, and the constituent material is BYNEL2714 of DuPont Company, and the resin blended with it is Engage8003 of Dow, and the blending ratio is 90:10.

[0052] The thickness of layer C is 75 μm, the content of polypropylene is 30%, the content of polyethylene is 50%, and the content of SEBS is 20%. The PP material is Atofina's Z8453, the PE is Dow's Engage8003, and the suitable SEBS material is Kraton's G1650.

[0053] The layer D has a thickness of 90 μm, a polypropylene content of 60%, a polyethylene content of 30%, and a SEBS content of 10%. The PP material is Atofina's 3281, the PF is Versify2200, and the SEBS material is Kraton's G1652.

[0054] The thickness of the E layer is 15 μm, the content of polypropylene is between 75%, and the content of SEBS is 25%. The propylene / ethylene copolymer is Atofina's Z8453, and the SEBS material is Kr...

Embodiment 2

[0056] The thickness of layer A is 15 μm, and the polyester is soft polyester CP301 produced by Mitsubishi.

[0057] The thickness of layer B is 10 μm, and the constituent material is Orevac 18760 of Arkema, and the resin blended with it is Zales 7023 of Mitsubishi, and the blending ratio is 70:30.

[0058] The thickness of layer C is 70 μm, the content of polypropylene is 30%, the content of polyethylene is 50%, and the content of SEBS is 20%. The PP material is Mitsubishi's ZalesMC742, the PE is Dow's Engage8003, and the SEBS material is Kraton's G1651.

[0059] The layer D has a thickness of 95 μm, a polypropylene content of 60%, a polyethylene content of 30%, and a SEBS content of 10%. The PP material is Adflex Q100F of Basel1, the PE is Infuse9100, and the SEBS material is G1650 of Kraton.

[0060] The thickness of the E layer is 15 μm, the content of polypropylene is between 75%, and the content of SEBS is 25%. The propylene / ethylene copolymer is Adsyl 3C30F of Basell...

Embodiment 3

[0062] The thickness of layer A is 12 μm, and the polyester is Ecdel 9967 produced by Eastman.

[0063] The thickness of layer B is 10 μm, and the constituent material is Arkema's Orevac8760, and the resin blended with it is Basell Adflex Q100F, and the blending ratio is 75:25.

[0064]The thickness of layer C is 75 μm, the content of polypropylene is 70%, the content of polyethylene is 15%, and the content of SEBS is 15%. The PP material is Mitsubishi's Zales7023, the PE is Dow's Engage8003, and the SEBS material is Kraton's G1650.

[0065] The layer D has a thickness of 80 μm, a polypropylene content of 65%, a polyethylene content of 25%, and a SEBS content of 10%. The PP material is Atofina's 6232, the PE is Exceed2018CA, and the SEBS material is Kraton's G1675.

[0066] The thickness of the E layer is 20 μm, the content of polypropylene is between 75%, and the content of SEBS is 25%. The propylene / ethylene copolymer is Atofina's Z8453, and the SEBS material is Kraton's ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com