High barrier paint for bi-oriented polyester thin film and preparing method thereof

A biaxially oriented polyester, high-barrier technology, applied in coatings and other directions, can solve the problems of opaque environment, low cost, unfriendliness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

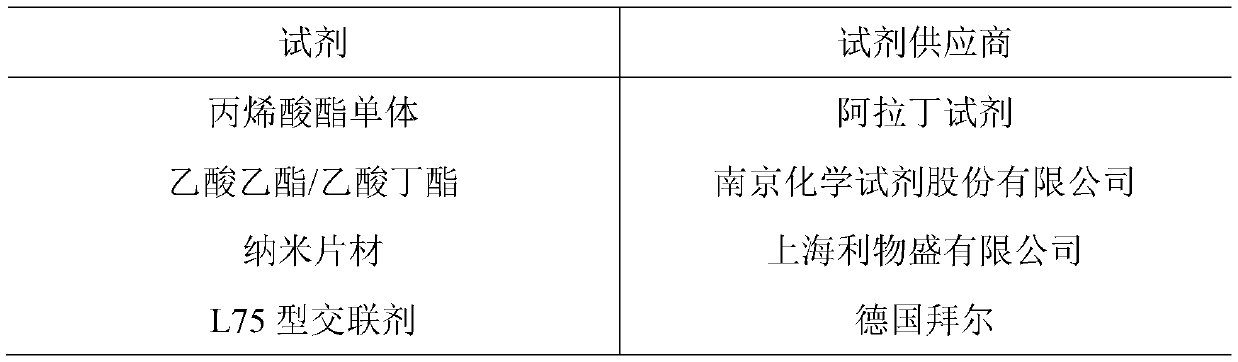

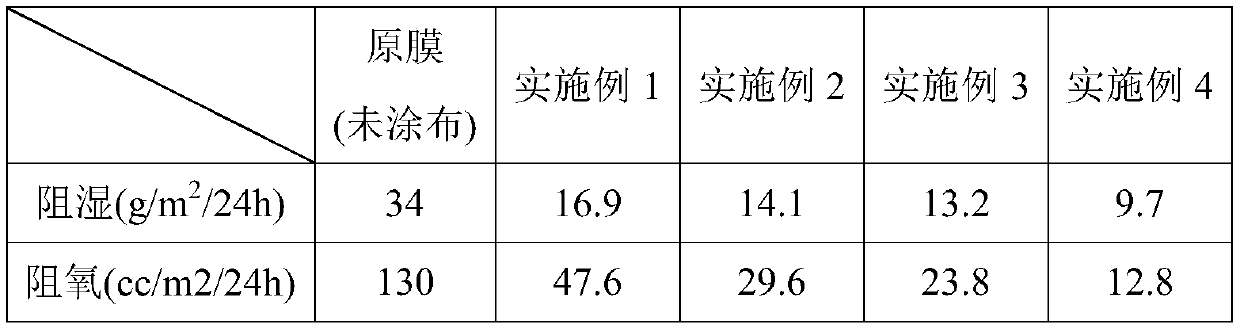

Embodiment 1

[0043] A high-barrier coating for biaxially stretched polyester film, comprising the following components by mass percentage: 20 parts of acrylate copolymer, 77.9 parts of mixed solvent, 0.1 part of nano-flaky clay, and 2 parts of isocyanate crosslinking agent share.

[0044] Wherein, the comonomer of the acrylate copolymer comprises, by mass percentage, 53 parts of methyl methacrylate, 40 parts of methyl acrylate, and 7 parts of hydroxyethyl methacrylate; the mixed solvent has a mass ratio of 1:1 mixed solvent of ethyl acetate and butyl acetate; the average particle size of the nano-flaky clay is 100nm, and the thickness is 20nm.

[0045] A kind of preparation method for the high barrier coating of biaxially stretched polyester film, by mass percentage:

[0046] (1) Weigh 8 parts of methyl acrylate, 10.6 parts of methyl methacrylate, 1.4 parts of hydroxyethyl methacrylate, 20 parts in total and 73 parts of mixed solvent and add them to the reaction kettle. At a stirring spee...

Embodiment 2

[0051] A high-barrier coating for biaxially stretched polyester film, comprising the following components by mass percentage: 25 parts of acrylate copolymer, 72.95 parts of mixed solvent, 0.05 part of nano-flaky clay, and 2 parts of isocyanate crosslinking agent share.

[0052] Wherein, the comonomer of the acrylate copolymer comprises, by mass percentage, 80 parts of methyl methacrylate, 13 parts of methyl acrylate, and 7 parts of hydroxyethyl methacrylate; the mixed solvent has a mass ratio of A 1:1 mixed solvent of ethyl acetate and butyl acetate; the average particle size of the nano-flaky clay is 100 nm, and the thickness is 15 nm.

[0053] A kind of preparation method for the high barrier coating of biaxially stretched polyester film, by mass percentage:

[0054] (1) Weigh 3.25 parts of methyl acrylate, 20 parts of methyl methacrylate, 1.75 parts of hydroxyethyl methacrylate, 25 parts in total and 68 parts of mixed solvent and add them to the reactor. Under the conditi...

Embodiment 3

[0059] A high-barrier coating for biaxially stretched polyester film, comprising the following components by mass percentage: 30 parts of acrylate copolymer, 67.92 parts of mixed solvent, 0.08 part of nano-flaky clay, and 2 parts of isocyanate crosslinking agent share.

[0060] Wherein, the comonomer of the acrylate copolymer comprises, by mass percentage, 73 parts of methyl methacrylate, 20 parts of methyl acrylate, and 7 parts of hydroxyethyl methacrylate; the mixed solvent has a mass ratio of 1:1 mixed solvent of ethyl acetate and butyl acetate; the average particle size of the nano-flaky clay is 160nm, and the thickness is 15nm.

[0061] A kind of preparation method for the high barrier coating of biaxially stretched polyester film, by mass percentage:

[0062](1) Weigh 6 parts of methyl acrylate, 21.9 parts of methyl methacrylate, 2.1 parts of hydroxyethyl methacrylate, 30 parts in total, and 63 parts of mixed solvent and add them to the reaction kettle. At a stirring sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com