Preparation method of supermolecule/rubber airtight materials

A rubber gas and supramolecular technology, which is applied in the field of improving the gas barrier properties of rubber, can solve the problems of difficult to achieve comprehensive properties of materials, weak geometric effects, and large length and width of clay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

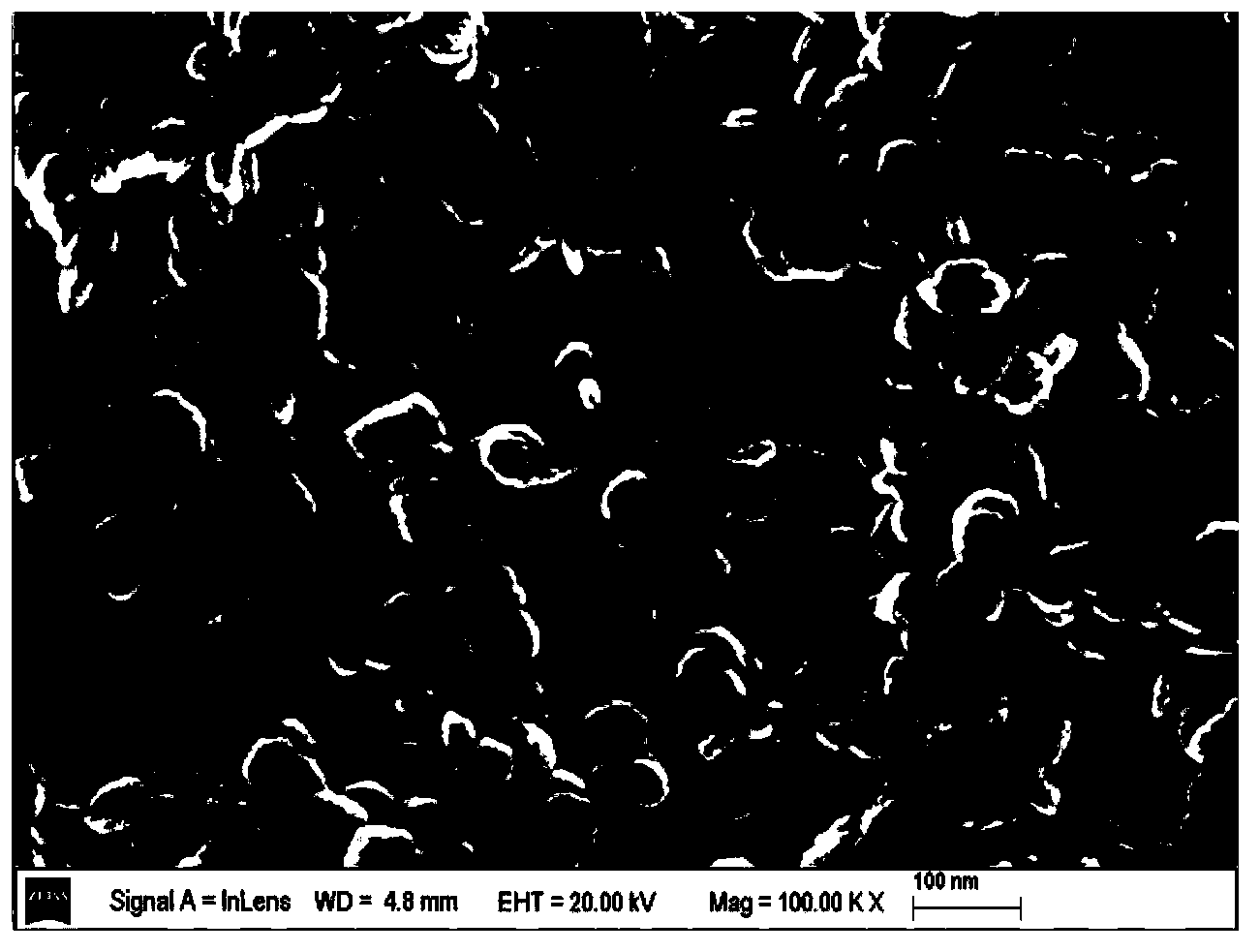

Image

Examples

Embodiment 1

[0024] The hydrotalcite / nitrile rubber compound was prepared by emulsion compounding method. Disperse 0.2 g of hydrotalcite in 40 ml of deionized water, stir to disperse evenly to obtain a hydrotalcite solution with a solid content of 0.5 wt%. Then mix and stir the hydrotalcite solution and 100g reactive latex (nitrile latex with a solid content of 40%) to obtain a hydrotalcite / nitrile latex mixture; then pour the mixed solution into 3000ml1wt% calcium chloride solution for flocculation, and the flocculation The product was dried in a blast drying oven at 60°C for 24 hours to prepare a hydrotalcite / nitrile rubber composition; then the hydrotalcite / nitrile rubber composition was added with additives (5 parts of zinc oxide, stearic acid 2 parts, 3 parts of anti-aging agent 4010NA, 1.4 parts of CZ, 0.1 part of M, and 2.8 parts of sulfur) were mixed to obtain a rubber compound. The content of hydrotalcite in the final material was 0.2 phr and that of nitrile rubber was 100 phr. ...

Embodiment 2

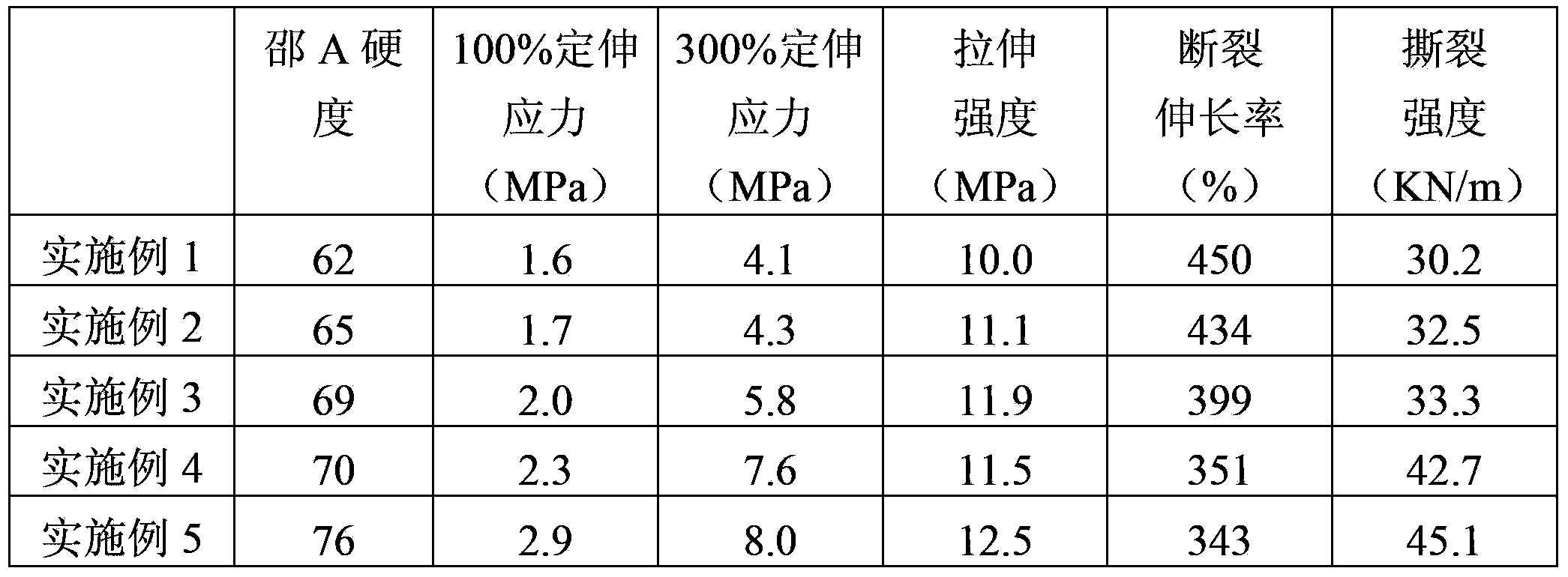

[0027] The difference from Example 1 is that 0.5g of hydrotalcite is dispersed in 100ml of deionized water, with a solid content of 0.5wt%, and compounded with 100g of reactive latex (nitrile latex with a solid content of 40%), and the rest of the process and operating steps are the same Example 1. The content of hydrotalcite in the final material was 0.5 phr and that of nitrile rubber was 100 phr. The mechanical properties of the vulcanizate are listed in Table 1. The gas barrier properties of the vulcanizate measured under this test condition are shown in Table 2.

Embodiment 3

[0029] The difference from Example 1 is that 3g of hydrotalcite is weighed and dispersed in 600ml of deionized water, with a solid content of 0.5wt%, and compounded with 100g of reactive latex (nitrile latex with a solid content of 40wt%), and the remaining processes and operating steps are implemented in the same manner example 1. The content of hydrotalcite in the final material was 3 phr and that of nitrile rubber was 100 phr. The mechanical properties of the vulcanizate are listed in Table 1. The gas barrier properties of the vulcanizate measured under this test condition are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com