High-strength and high-toughness polylactic acid composite film with antimicrobial and barrier properties

A technology of tough polylactic acid and composite film, applied in the field of preparation of polylactic acid composite film, can solve the problems of high brittleness, single function, poor mechanical properties, etc., and achieve the effects of improving mechanical properties, improving gas barrier properties, and improving dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

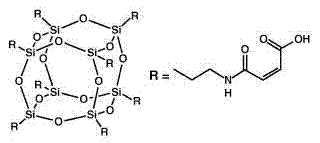

[0033] A high-strength polylactic acid composite film with antibacterial barrier properties, the film raw materials include polylactic acid, EVOH, polylactic acid grafted glycidyl methacrylate, ethylene octene copolymer grafted glycidyl methacrylate, eight-armed Maleic anhydride POSS, Nano TiO 2 , antioxidant and anti-ultraviolet agent. The film is formed by multi-layer co-extrusion. It is also characterized by:

[0034] The mass ratio (calculated by mass parts) of each component in the raw material is:

[0035] Polylactic acid: 100

[0036] EVOH: 45

[0037] Polylactic acid grafted glycidyl methacrylate: 8.4

[0038] Glycidyl methacrylate grafted ethylene octene: 7.6

[0039] Eight-arm maleic anhydride POSS: 2.8

[0040] Nano-TiO 2 : 3.6

[0041] Antioxidant: 2.5

[0042] Its preparation process is:

[0043] (1) Vacuum dry all raw materials at 50 degrees for 24 hours and set aside;

[0044] (2) After high-speed blending of polylactic acid, EVOH, polylactic acid gr...

Embodiment 2

[0055] A high-strength polylactic acid composite film with antibacterial barrier properties, the film raw materials include polylactic acid, EVOH, polylactic acid grafted glycidyl methacrylate, ethylene octene copolymer grafted glycidyl methacrylate, eight-armed Maleic anhydride POSS, Nano TiO 2 , antioxidant and anti-ultraviolet agent. The film is formed by multi-layer co-extrusion. It is also characterized by:

[0056] The mass ratio (calculated by mass parts) of each component in the raw material is:

[0057] Polylactic acid: 100

[0058] EVOH: 35

[0059] Polylactic acid grafted glycidyl methacrylate: 7.5

[0060] Glycidyl methacrylate grafted ethylene octene: 7.5

[0061] Eight-arm maleic anhydride POSS: 3.2

[0062] Nano-TiO 2 :4

[0063] Antioxidants: 3

[0064] Its preparation process is:

[0065] (1) Vacuum dry all raw materials at 50 degrees for 24 hours and set aside;

[0066] (2) After high-speed blending of polylactic acid, EVOH, polylactic acid grafte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com