Transparent oxide film and process for producing same

A technology of transparent oxide and manufacturing method, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, vacuum evaporation coating, etc., can solve the problems of function decline, lower refractive index, poor crystal phase, etc., and achieve high transparency, Effect of low refractive index and high gas barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

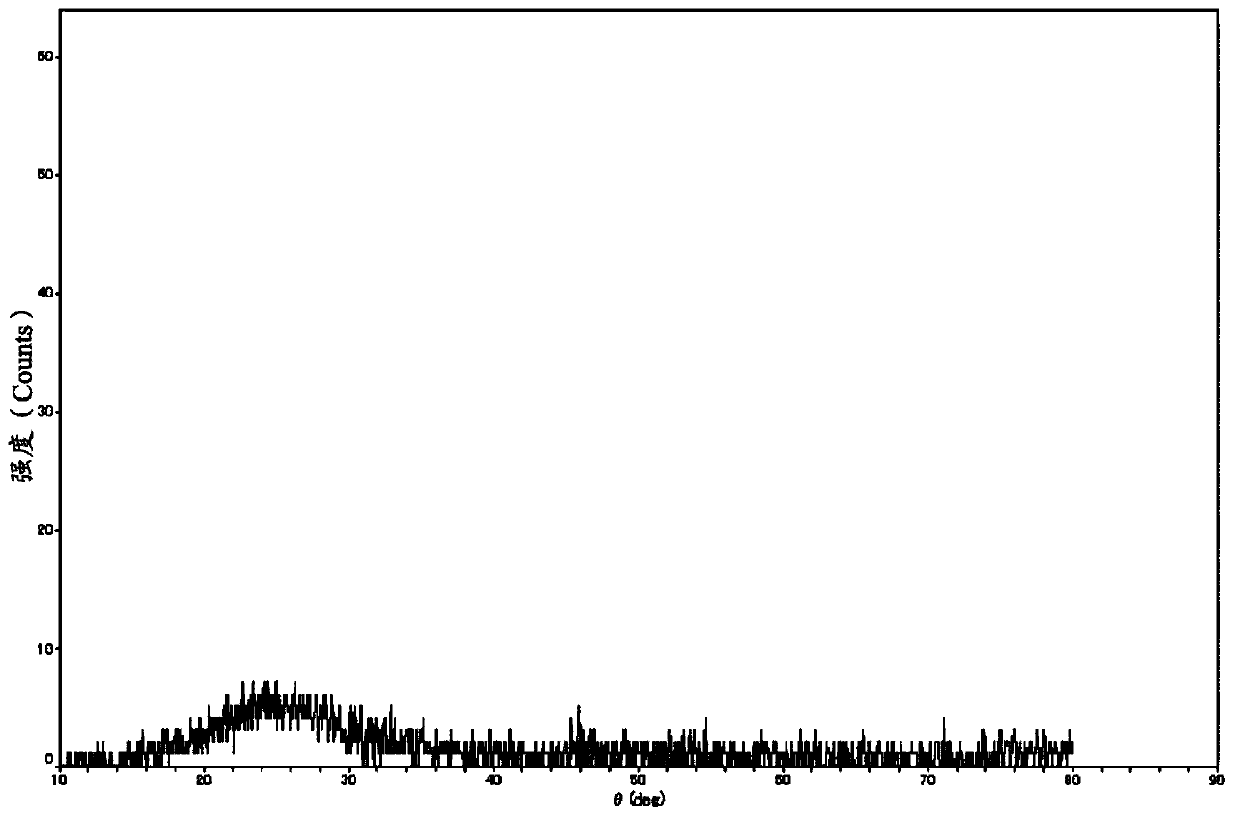

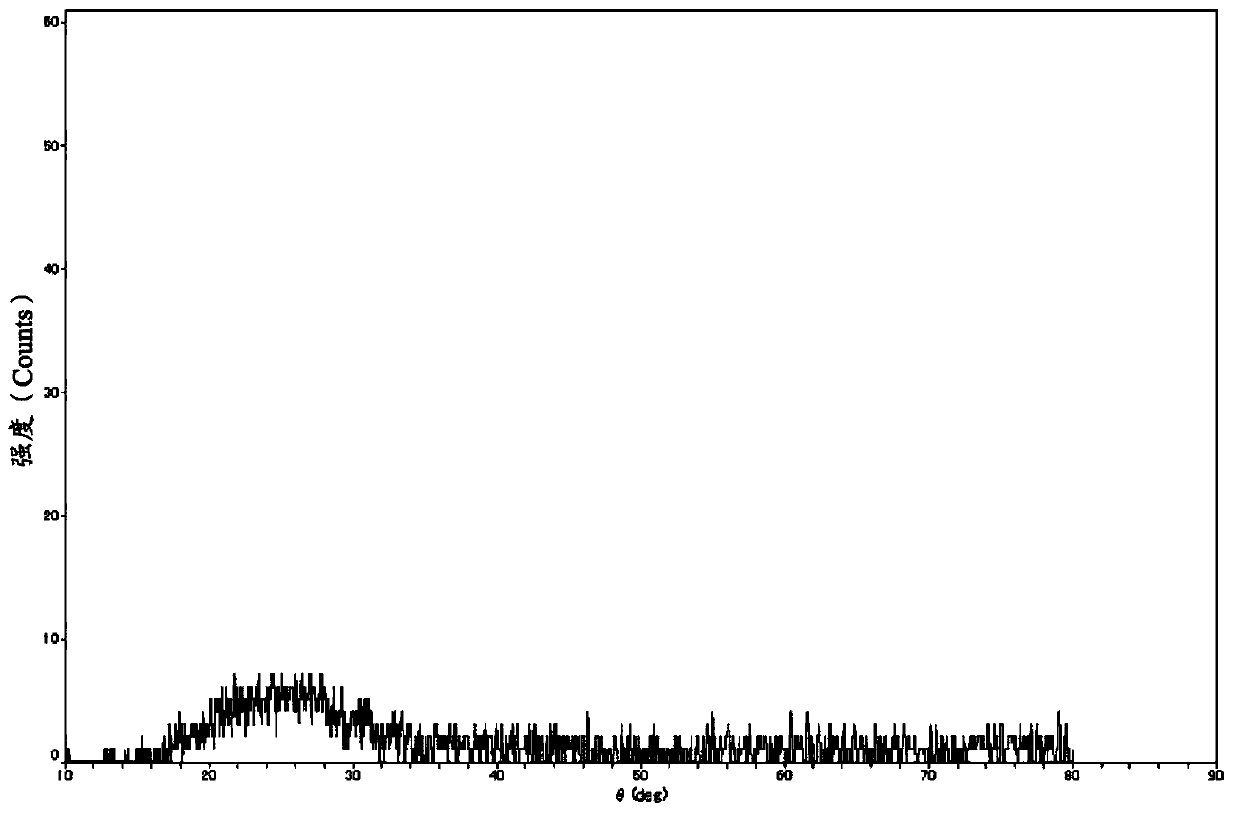

[0044] Below, refer to Figure 2 to Figure 8 The evaluation results of Examples of the transparent oxide film produced based on the above-mentioned present embodiment will be described.

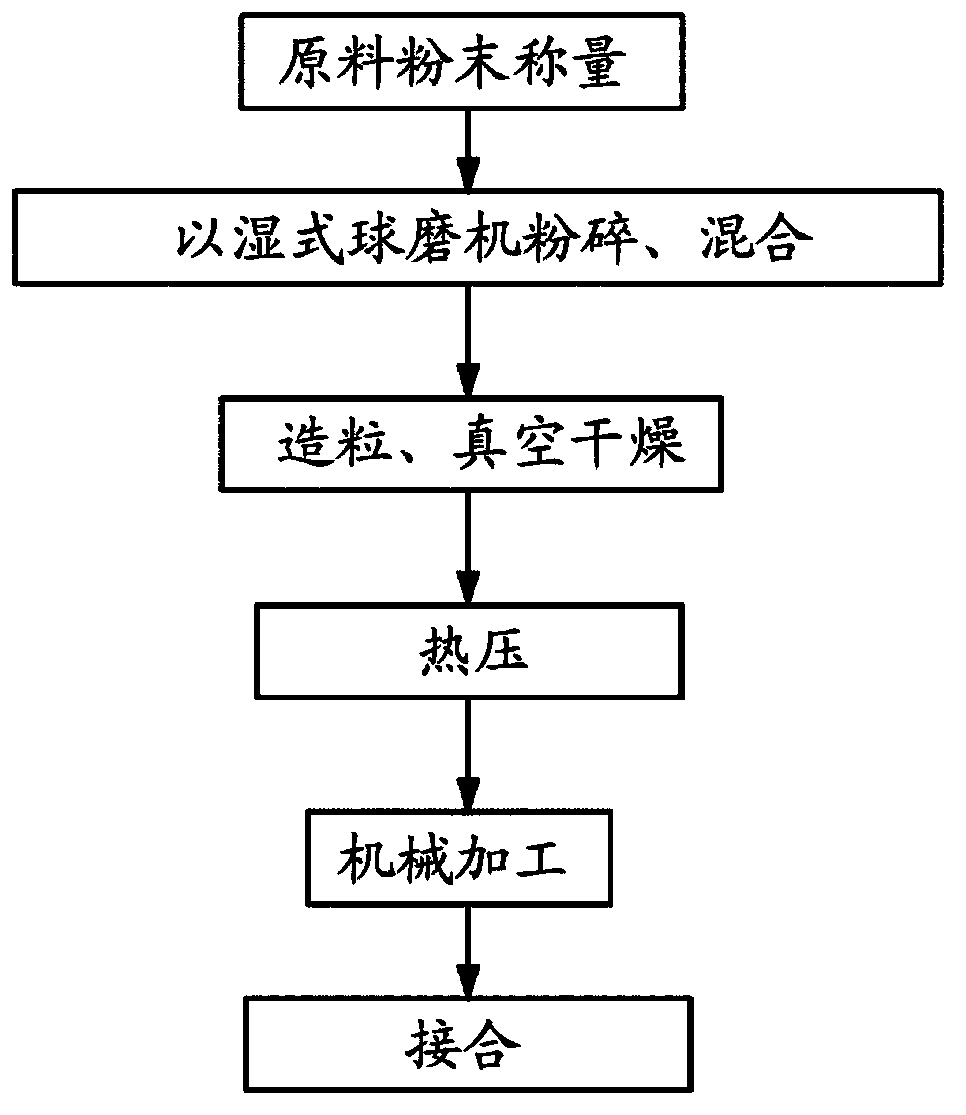

[0045] Production of Examples of the present invention was carried out under the following conditions. First to Al 2 o 3 Powder, SiO 2 Powder and ZnO powder were weighed to achieve the composition ratio shown in Table 1, and the obtained powder and zirconia balls (a ball with a diameter of 5 mm and a ball with a diameter of 10 mm balls) were placed in a 10 L plastic container (polyethylene pot), and wet-mixed with a ball mill for 48 hours to obtain a mixed powder. In addition, alcohol is used as a solvent, for example.

[0046] Next, after drying the obtained mixed powder, it is granulated, for example, with a sieve with a mesh size of 250 μm, and after further vacuum drying, it is dried at 1200° C. 2 The pressure was hot-pressed in vacuum for 5 hours as a sintered body. The hot-presse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com