Preparation method of glycidyl methacrylate melt-grafted polyolefin material

A technology of glycidyl ester and methacrylic acid, which is applied in the field of preparation of glycidyl methacrylate melt-grafted polyolefin materials, can solve problems such as inability to effectively quench segment free radicals, and achieves low cross-linking degree and molecular weight. High, inhibiting the effect of degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

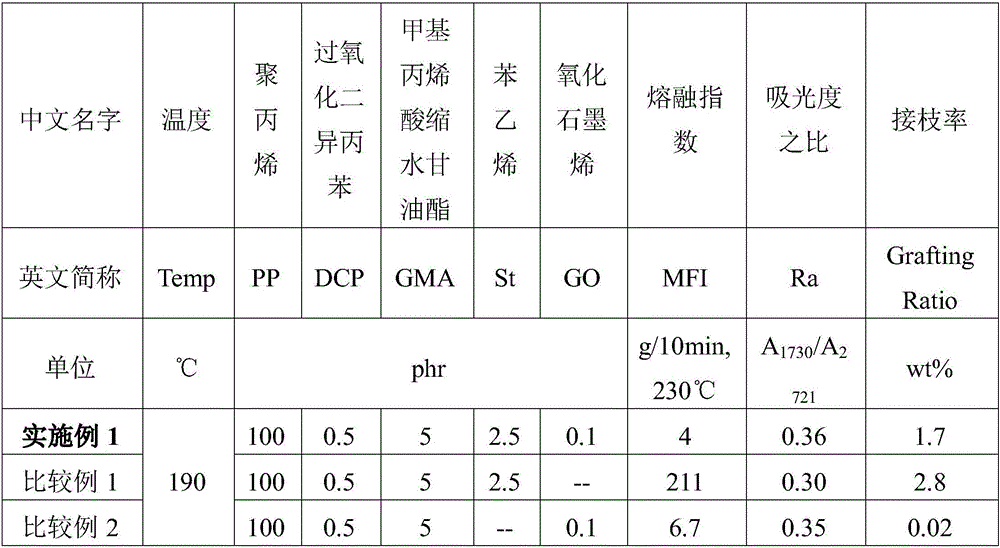

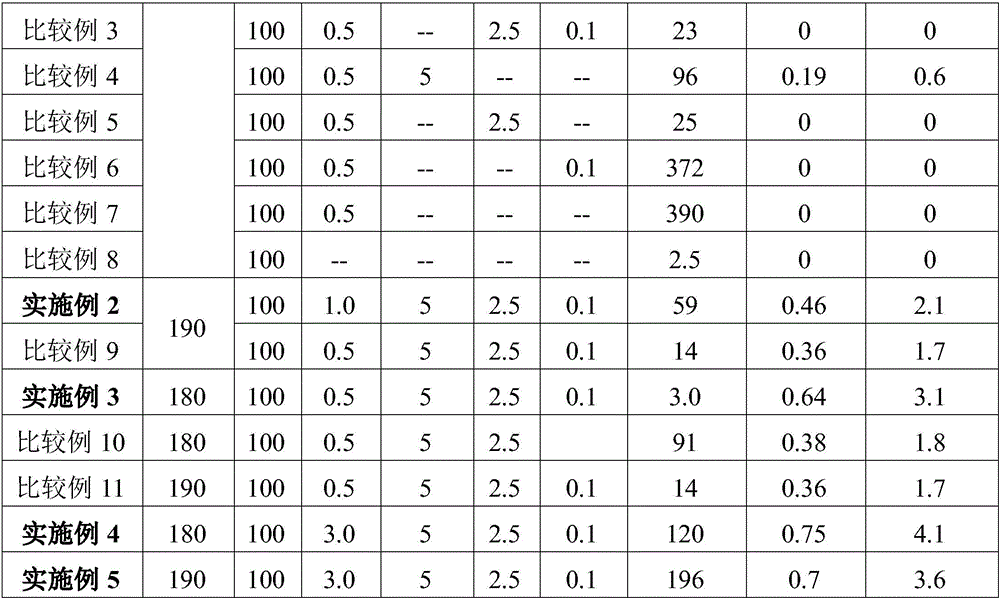

[0033] Example 1: PP / DCP / GMA / St / GO

[0034] PP / DCP / GMA / GO were mixed according to the weight ratio of 100 / 0.5 / 5 / 0.1 (the polypropylene weighed 46g) and stirred evenly by hand, added to the internal mixer, and then added 2.5phr of liquid St, 190°C Mix at a speed of 50 rpm for 5 min.

[0035] The test results of the samples are shown in Table 1.

Embodiment 2

[0060] Embodiment 2: PP / DCP / GMA / St / GO (changing DCP content is 1.0phr)

[0061] PP / DCP / GMA was mixed according to the weight ratio GO / 100 / 1.0 / 5 / 0.1 (including polypropylene weighed 46g) and stirred evenly by hand, added to the internal mixer, and then added 2.5phr of liquid St, 190°C Mix at a speed of 50 rpm for 5 min.

[0062] The test results of the samples are shown in Table 1.

Embodiment 3

[0066] Example 3: PP / DCP / GMA / St / GO, 180°C

[0067] PP / DCP / GMA / GO are mixed according to the weight ratio of 100 / 0.5 / 5 / 0.1 (the polypropylene weighs 46g) and stirred evenly by hand, then added to the internal mixer, and then added 2.5phr of liquid St, 180°C Mix at a speed of 50 rpm for 5 min.

[0068] The test results of the samples are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com