Preparation method for lead halide caesium perovskite quantum dot colloid and quantum dot fluorescent powder

A technology of lead cesium halide perovskite and quantum dots, which is applied in the field of materials, can solve problems such as instability in the use process of lead cesium halide perovskite quantum dots, achieve high luminous efficiency, solve instability, and good water and oxygen resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

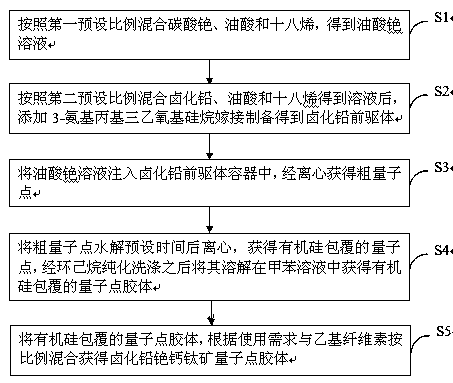

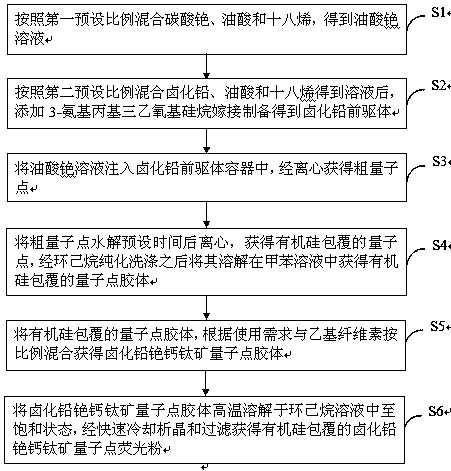

[0031] Aiming at the technical problem of insufficient stability of lead cesium halide perovskite quantum dots in the prior art, the present invention provides a brand-new method for stabilizing lead cesium halide perovskite quantum dots, using organic silicon and ethyl The cellulose chemical bonds are used to coat the quantum dots to avoid the damage of the external water and oxygen environment to the quantum dots, and to achieve the improvement of stability. Specifically, such as figure 1 Shown, include in this lead halide cesium perovskite quantum dot colloid preparation method:

[0032] S1 mixes cesium carbonate, oleic acid and octadecene according to a first preset ratio to obtain a cesium oleate solution;

[0033] S2 After mixing lead halide, oleic acid and octadecene according to a second preset ratio to obtain a solution, adding 3-aminopropyltriethoxysilane to prepare a lead halide precursor;

[0034] S3 Inject the cesium oleate solution into the lead halide precurso...

Embodiment 1

[0050] First, weigh 0.8g (grams) of cesium carbonate, 2.5ml (ml) of oleic acid and 30ml (ml) of octadecene in proportion, after degassing, heat to 120°C (°C) in an inert gas environment to dissolve them To complete clarification, cesium oleate solution is obtained, preheated to be used in the next step; after that, weigh 0.032g lead chloride, 0.156g lead bromide, 0.2ml oleic acid and 15ml octadecene in proportion, and heat in an inert gas Dissolve in a protected environment for 30 minutes, then add 1.5ml of 3-aminopropyltriethoxysilane to graft to prepare the lead halide precursor; after that, preheat the obtained 1.5ml cesium oleate at 140°C and inject the obtained lead halide precursor React in the container, and quickly transfer to ice water for cooling to obtain crude quantum dots, centrifuge after hydrolysis for 1 hour to obtain silicone-coated quantum dots; wash the obtained quantum dots with 10ml cyclohexane solution and dissolve them in 10ml Silicone-coated quantum dot...

Embodiment 2

[0054] First, weigh 0.8g of cesium carbonate, 2.5ml of oleic acid and 30ml of octadecene in proportion, and after degassing, heat it to 120°C under an inert gas protection environment to dissolve it until it is completely clear to obtain a cesium oleate solution, preheat To be used in the next step; after that, weigh 0.2g of lead bromide, 0.22ml of oleic acid and 15ml of octadecene in proportion, heat and dissolve for 30min under an inert gas protection environment, and then add 1.5ml of 3-aminopropyltriethyl The lead halide precursor was prepared by oxysilane grafting; after that, the obtained 1.5ml cesium oleate was preheated at 140°C and injected into the obtained lead halide precursor container for reaction, and quickly transferred to ice water for cooling to obtain coarse quantum dots, hydrolyzed Centrifuge after 1.5h to obtain silicone-coated quantum dots; wash the obtained quantum dots with 15 ml of cyclohexane solution and dissolve them in 20ml of toluene solution to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Luminous wavelength | aaaaa | aaaaa |

| Half width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com