Solar cell packaging film

A technology for solar cells and packaging films, applied in circuits, photovoltaic power generation, electrical components, etc., to achieve high weather resistance, improve conversion efficiency, and reduce temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Preparation steps of the present invention:

[0041] Step 1, carrying out corona treatment on both sides of the transparent support;

[0042] Step 2: prepare a wear-resistant filter coating solution, apply the coating solution on the surface of a transparent support, control the thickness of the coated film through the selection of vehicle speed and anilox roller, and perform UV curing after drying to obtain a wear-resistant filter Floor;

[0043] Step 3: Carry out vacuum coating on the other side of the transparent support, and obtain a gas barrier layer by controlling the speed of the vehicle and the film forming process.

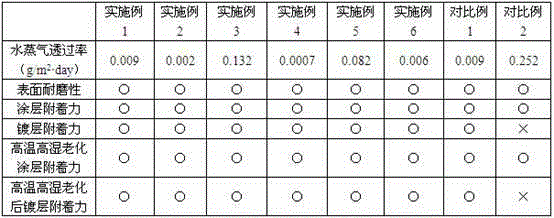

Embodiment 1

[0046] ETFE film with a thickness of 50 μm is selected, after surface cleaning and pretreatment, corona treatment is carried out;

[0047] Prepare a wear-resistant coating solution, use an anilox roller to coat a wear-resistant filter coating on the surface of the ETFE film, the thickness of the coating is controlled to 3 μm, and after drying at 80°C, use ultraviolet light to cure.

[0048] After curing, PECVD is used to deposit a silicon oxide film with a thickness of 300 nm on the surface of the uncoated ETFE film to obtain the required solar cell front-side packaging film material.

[0049] The coating liquid composition as shown in embodiment 1 is:

[0050] A wear-resistant filter coating solution is composed of ITO nanoparticles with a diameter of 10 nanometers and a transparent wear-resistant coating solution, wherein the mass percentage of ITO in the wear-resistant filter coating solution is 10%;

[0051] The transparent wear-resistant coating solution is an ultraviole...

Embodiment 2

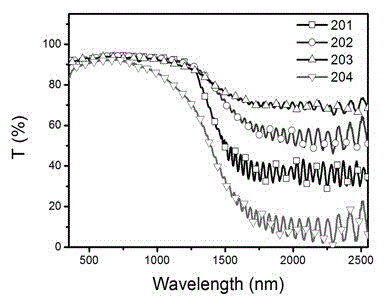

[0054] In Example 1, the mass percentage of ITO nanoparticles in the wear-resistant filter coating solution is 5%, and the thickness of the deposited silicon oxide film is 400nm. Except for this, the same operation as Example 1 is performed. The optical transmittance test and characterization of the obtained solar cell encapsulation film were carried out, and the results were as follows: figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com