Touch control type organic light-emitting display panel

A light-emitting display, touch-sensitive technology, applied in organic semiconductor devices, semiconductor devices, electrical components, etc., can solve the problems of corrosion of organic functional layers and motor materials, affecting device life, blue light intensity, etc., to enhance performance and improve color. Purity, good eye protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

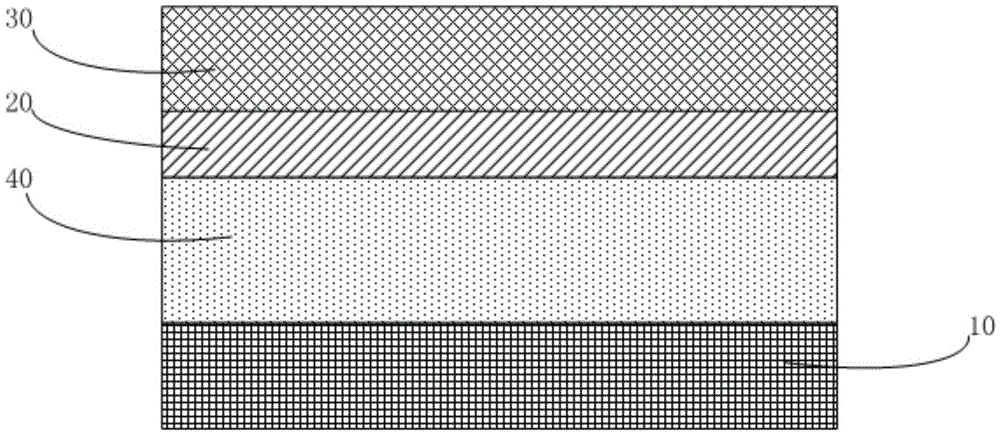

[0023] see figure 1 , is a schematic diagram of a touch-sensitive organic light-emitting display panel according to Embodiment 1 of the present invention, which includes an organic light-emitting diode device 10 , a polarizer 20 stacked on the light-emitting surface of the organic light-emitting diode device 10 , and a polarizer positioned between the polarizers 20 The touch panel 30 on the top; wherein, a dielectric layer 40 is provided between the polarizer 20 and the organic light emitting diode device 10 .

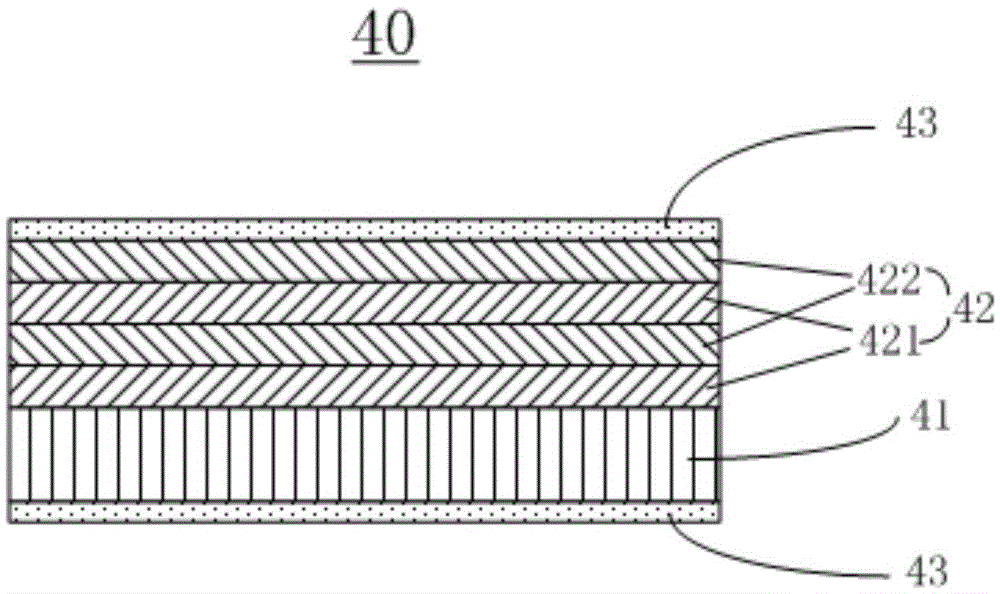

[0024] see figure 2 , the dielectric layer 40 includes a film substrate 41 and a Bragg reflector layer 42 formed on the film substrate.

[0025] The Bragg reflector layer 42 includes a first layer and a second layer alternately stacked along its thickness direction, the refractive index of the second layer is at least 0.5 higher than that of the first layer, and the one closest to the film substrate 41 is the second layer. layer. The Bragg reflector layer 42 has n ...

Embodiment 2

[0036] like image 3 As mentioned above, the schematic diagram of the touch-sensitive organic light emitting display panel of the second embodiment.

[0037] The difference from Embodiment 1 is that the dielectric layer 40 is located between the polarizer 20 and the touch panel 30 .

[0038] Others are the same as in Embodiment 1, and will not be repeated here.

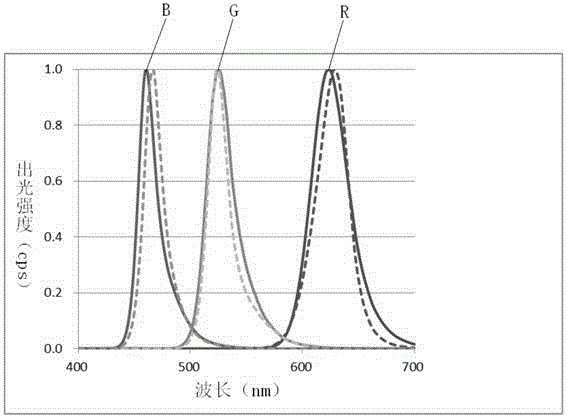

[0039]In the touch-sensitive organic light-emitting display panel of the present invention, the inventors have found through a lot of research that a specific Bragg The dielectric layer 40 of the reflector layer structure, on the one hand, can greatly reduce the blue light below 438nm that is harmful to human eyes, thereby achieving the purpose of eye protection; secondly, the inventor unexpectedly found that the Bragg The structure of the reflector layer 42 can not only play the role of controlling the microcavity, but also form a resonant cavity effect corresponding to the organic optical microcavity in the organi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com