Flexible touch screen base material and preparation method thereof

A flexible touch screen and base material technology, applied in coatings, instruments, electrical digital data processing, etc., can solve problems such as thick thickness, restrictions on flexible applications, and impact on the flexibility and bendability of flexible OLEDs, to achieve enhanced packaging effects, TFE The effect of enhancing water and oxygen blocking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the above-mentioned flexible TP substrate is to add nanomaterials to the main material of the substrate, mix them uniformly, and then form a film by coating.

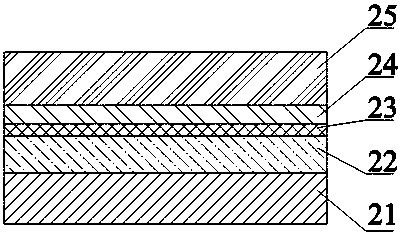

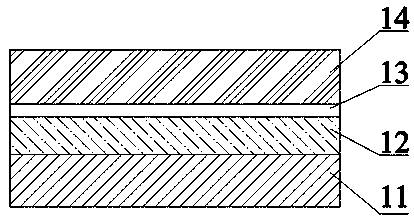

[0035] Such as figure 2 As mentioned above, the flexible OLED display panel containing the flexible TP base material of the present invention includes a flexible OLED component 21 at the bottom, a thin film encapsulation structure 22 located on the flexible OLED component 21, and a flexible TP substrate directly coated on the thin film encapsulation structure 22. material 23 and the flexible touch screen 24 directly disposed on the flexible touch screen substrate 23 .

Embodiment 1

[0038] Nano-silicon nitride with a particle size of 10nm and a weight ratio of 0.1% is dissolved in a transparent PI solution by ultrasonic oscillation, and then stirred at a constant speed under certain conditions for a certain period of time to form a certain copolymerization modification between nano-silicon nitride and transparent PI. The compatibility between the two is improved, the chemical bond is formed between the two, and the interfacial bonding between the two is enhanced. Then the prepared flexible TP substrate is directly coated on the TEF by coating, while the flexible TP It is directly arranged on the flexible TP substrate, and the thickness of the prepared flexible TP substrate is 2-40 μm.

Embodiment 2

[0040] Nano-silicon nitride with a particle size of 60nm and a weight ratio of 50% is dissolved in a transparent PI solution by ultrasonic oscillation, and then stirred at a constant speed under certain conditions for a certain period of time to form a certain copolymerization modification between nano-silicon nitride and transparent PI. The compatibility between the two is improved, the chemical bond is formed between the two, and the interfacial bonding between the two is enhanced. Then the prepared flexible TP substrate is directly coated on the TEF by coating, while the flexible TP It is directly arranged on the flexible TP substrate, and the thickness of the prepared flexible TP substrate is 2-40 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com