Flexible packaging adhesive film for flexible OLED device

A flexible packaging and adhesive film technology, which is applied in the manufacture of electric solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of burnout of the organic light-emitting layer of OLED devices, side leakage of packaged devices, and no heat dissipation layer, etc., to achieve increased Water-blocking and oxygen-blocking properties, solving side leakage, and simplifying the packaging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

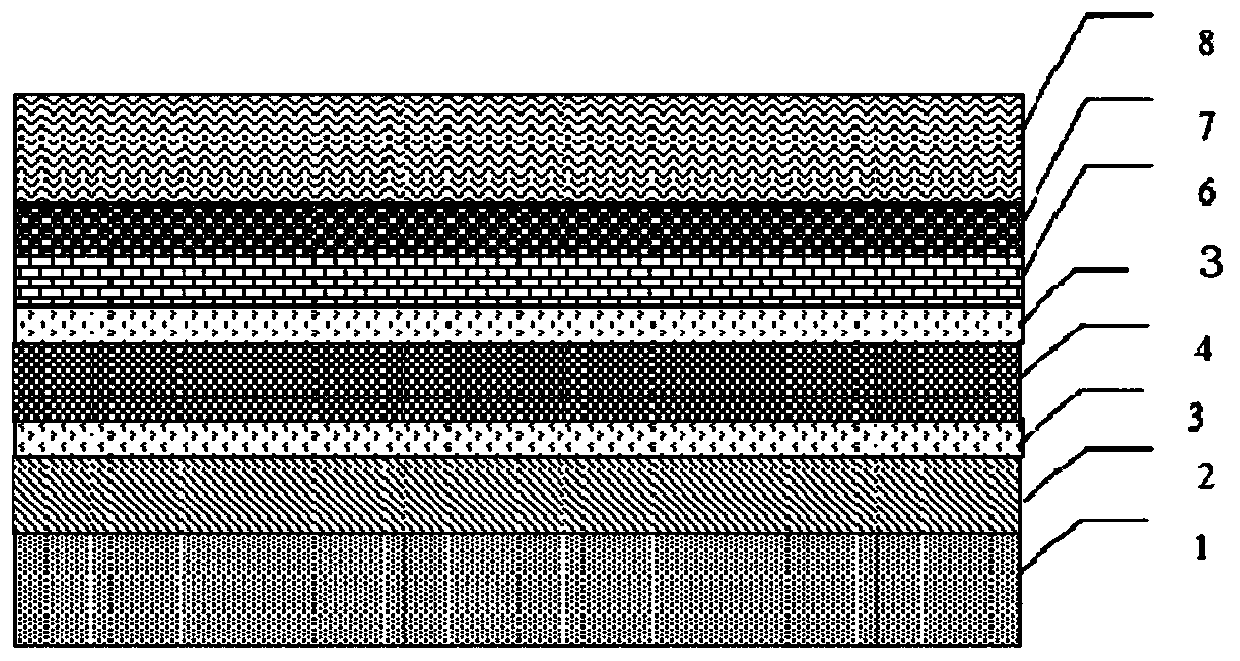

Embodiment 1

[0035] Choose 50μm PET, first slit-coat a layer of polyurethane organic planarization layer with a thickness of 0.1μm; then use PECVD to plate a layer of 200nm silicon oxide film on its surface; then coat a layer with a thickness of 5μm on its surface An organic water-absorbing layer containing 1wt% calcium oxide; then a layer of 15nm aluminum oxide film is plated on its surface by PECVD; then a heat dissipation layer containing graphene with a thickness of 10 μm is screen-printed on its surface; A pressure-sensitive adhesive layer containing 10wt% alumina barrier particles with a thickness of 1.5 μm is coated on the surface with a microgravure; finally, a PET release film with a thickness of 12 μm is pasted on its surface. The flexible encapsulation adhesive film prepared in this example has a water vapor transmission rate of 5.1×10 -6 g / m 2 24h, the oxygen transmission rate is 3.4×10 -6 cc / m 2 24h atm.

Embodiment 2

[0037] Select 25μm PI, first scrape coat a layer of polyester organic planarization layer with a thickness of 5μm; then use magnetron sputtering to coat a layer of 20nm aluminum oxide film on its surface; then coat a layer of slit coating on its surface An organic water-absorbing layer containing 1wt% barium oxide with a thickness of 0.1 μm; then a layer of 100 nm silicon oxide film is plated on its surface by PECVD; Then, a layer of pressure-sensitive adhesive layer containing 5wt% magnesium oxide with a thickness of 20 μm is scraped on its surface; finally, a PE release film with a thickness of 50 μm is pasted on its surface. The water vapor transmission rate of the flexible packaging film prepared in this example is 4.1×10 -6 g / m 2 24h, the oxygen transmission rate is 3.2×10 -6 cc / m 2 24h atm.

Embodiment 3

[0039] Choose 175μm PET, first slit-coat a layer of acrylic resin organic planarization layer with a thickness of 0.5μm; then use ALD to plate a layer of 100nm silicon oxide film on its surface; then screen print a layer of thickness on its surface. 5 μm organic water-absorbing layer containing 10wt% calcium chloride; then a layer of 50nm silicon nitride film is plated on its surface by PECVD; Then, a layer of pressure-sensitive adhesive layer containing 1wt% boron nitride barrier particles with a thickness of 1.5 μm is scraped on its surface; finally, a PET release film with a thickness of 38 μm is pasted on its surface. The water vapor transmission rate of the flexible packaging film prepared in this example is 3.6×10 -6 g / m 2 24h, the oxygen transmission rate is 2.9×10 -6 cc / m 2 24h atm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com