Organic electroluminescent display device and manufacturing method and display device thereof

An electroluminescence and device technology, applied in the manufacturing of organic semiconductor devices, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of cumbersome process, high cost, difficult curling, etc., to simplify the production process and avoid thickening. , The effect of good water and oxygen resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

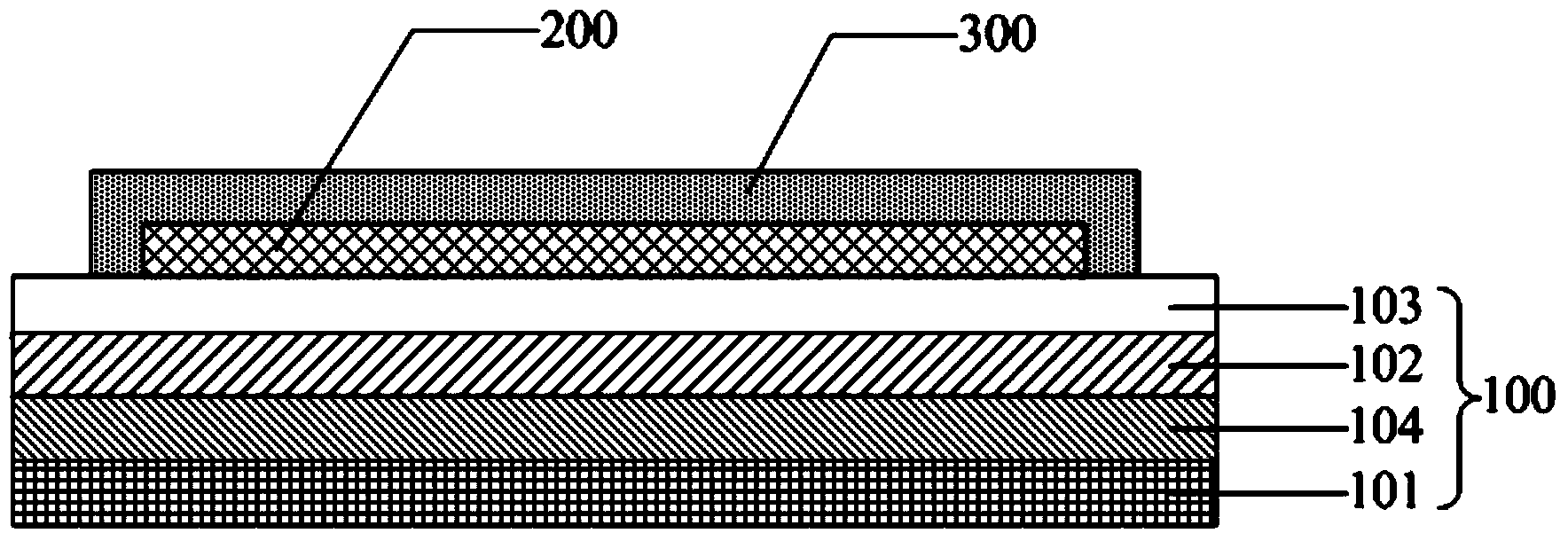

[0053] Example 1: Preparation by roll-to-roll method Figure 2a The substrate substrate shown, the schematic diagram of the specific process is shown in Figure 3a shown.

[0054] First, after the polarizing functional film layer 104 has undergone soaking and stretching processes, it is bonded to the main material film layer 101 and the first retardation film layer 102 on both sides of the polarizing functional film layer 104 in a roll-to-roll manner;

[0055] Afterwards, a water-blocking oxygen film layer 103 is deposited on one side of the first retardation film layer 102 to form the base substrate 100;

[0056] Finally, the organic electroluminescent pixel array 200 is fabricated on the base substrate 100 by using the existing process, and the organic electroluminescent pixel array 200 is packaged.

example 2

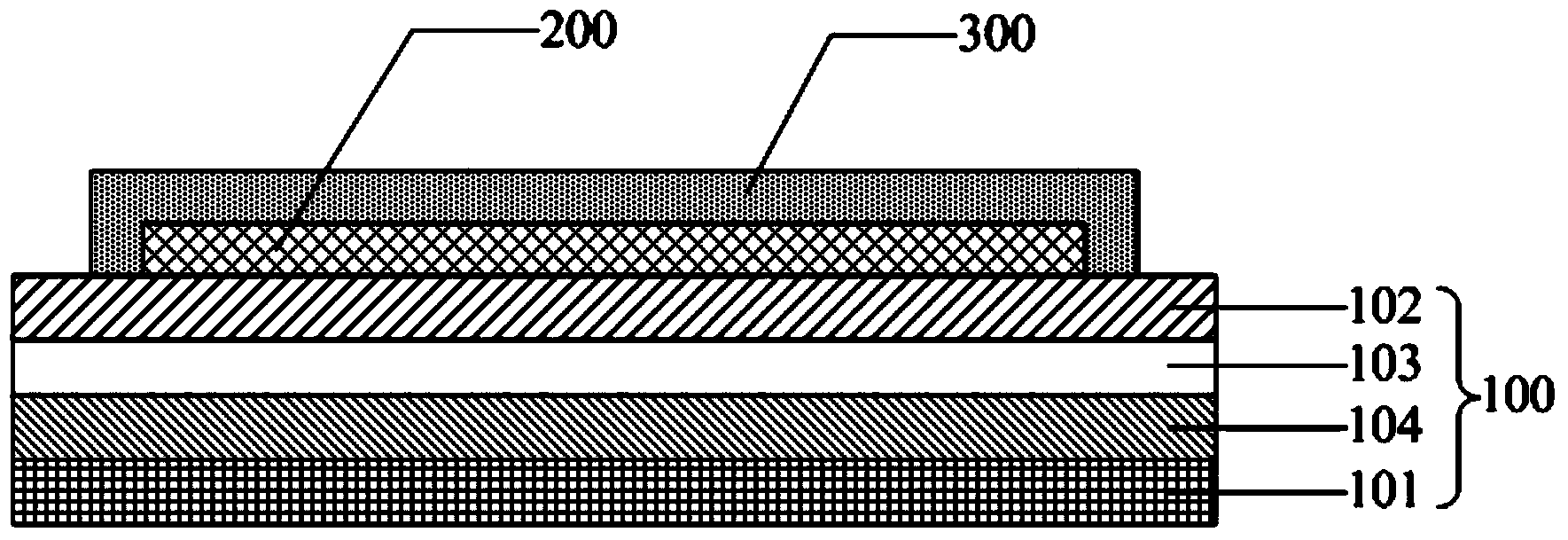

[0057] Example 2: Preparation by roll-to-roll method Figure 2b The substrate substrate shown, the schematic diagram of the specific process is shown in Figure 3b shown.

[0058] First, the polarizing functional film layer 104 is bonded to the main material film layer 101 in a roll-to-roll manner after soaking and stretching processes;

[0059] Afterwards, a water-blocking oxygen film layer 103 is deposited on one side of the polarizing functional film layer 104;

[0060] Then, the side where the water and oxygen blocking film layer 103 is deposited is laminated with the first retardation film layer 102 in a roll-to-roll manner to form the base substrate 100;

[0061] Finally, the organic electroluminescent pixel array 200 is fabricated on the base substrate 100 by using the existing process, and the organic electroluminescent pixel array 200 is packaged.

example 3

[0062] Example 3: Preparation by roll-to-roll method Figure 2c The substrate substrate shown, the schematic diagram of the specific process is shown in Figure 3c shown.

[0063] Firstly, after the polarizing functional film layer 104 has undergone soaking and stretching processes, it is bonded to the main material film layer 101 and the second retardation film layer 105 on both sides of the polarizing functional film layer 104 in a roll-to-roll manner;

[0064] Afterwards, a water-blocking oxygen film layer 103 is deposited on one side of the second retardation film layer 105;

[0065] Then, the side where the water and oxygen blocking film layer 103 is deposited is laminated with the first phase difference film layer 104 in a roll-to-roll manner to form the base substrate 100;

[0066] Finally, the organic electroluminescent pixel array 200 is fabricated on the base substrate 100 by using the existing process, and the organic electroluminescent pixel array 200 is packaged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com