Thin film packaging structure and organic photoelectric device

A technology for thin film packaging and optoelectronic devices, applied in the direction of electrical solid devices, electrical components, semiconductor devices, etc., can solve problems such as limited water and oxygen resistance, black spots, and extended edge water and oxygen erosion paths, so as to improve packaging performance and improve reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

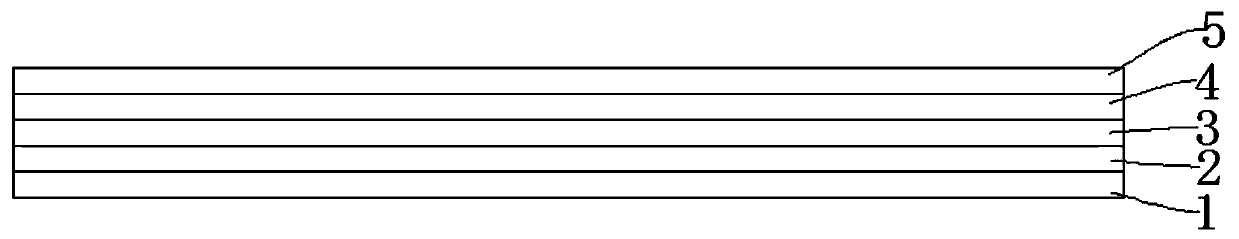

[0044] Such as figure 1 As shown, this embodiment provides a thin-film packaging structure, including a first inner packaging layer 1 , a metal layer 2 , a second inner packaging layer 3 , an adhesive layer 4 and an outer packaging layer 5 arranged sequentially from inside to outside. The first inner encapsulation layer 1 is an organic layer; the second inner encapsulation layer 3 is an inorganic layer or an organic-inorganic hybrid layer; the outer encapsulation layer 5 is a barrier film or a metal foil.

[0045] Wherein, the above "inner" refers to the side where the thin film packaging structure is in contact with the packaged device, and "outer" refers to the side of the thin film packaging structure away from the packaged device.

[0046]Wherein, the embodiment of the metal layer may optionally adopt any one of etching, mask, nanoimprinting, and laser transfer printing.

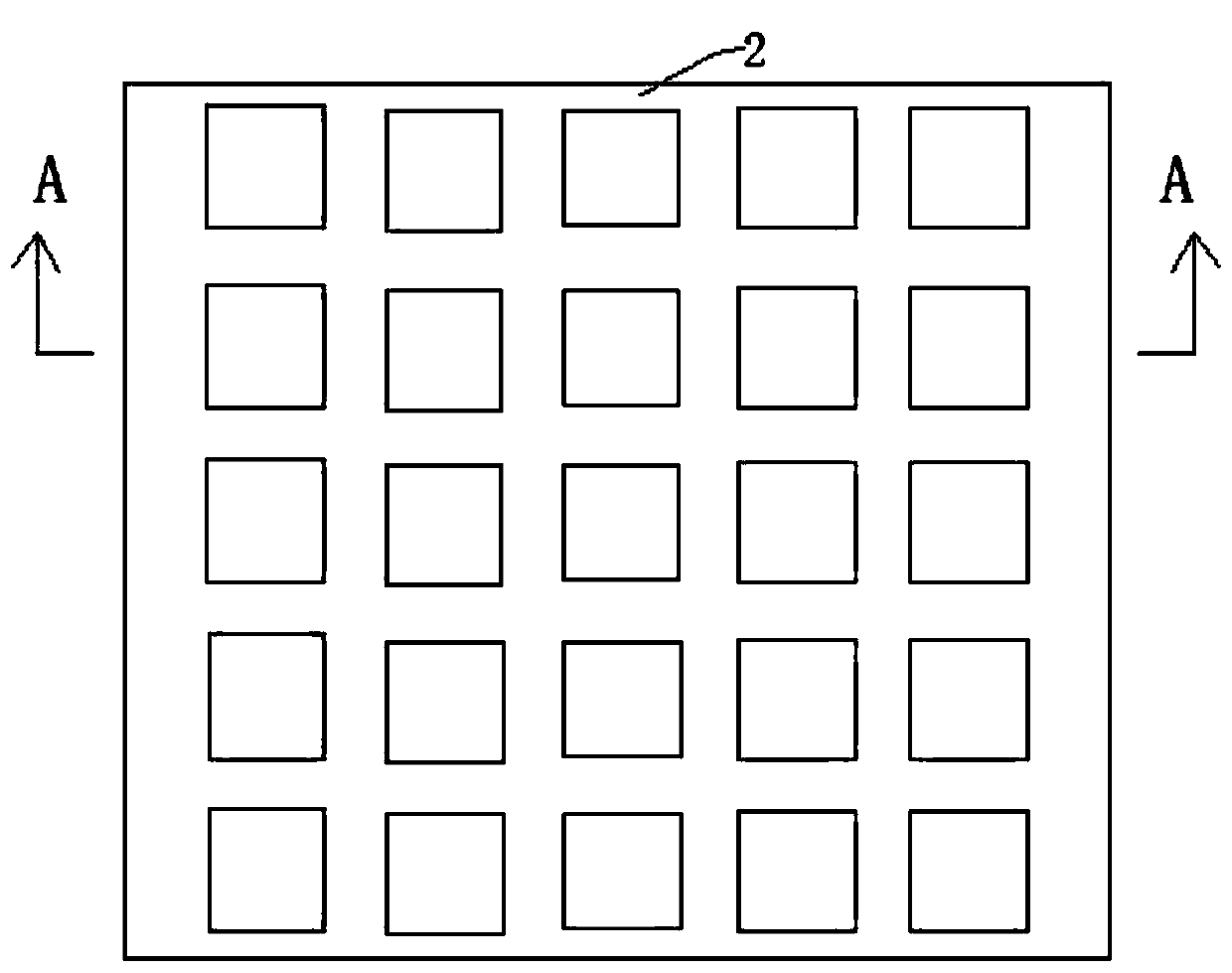

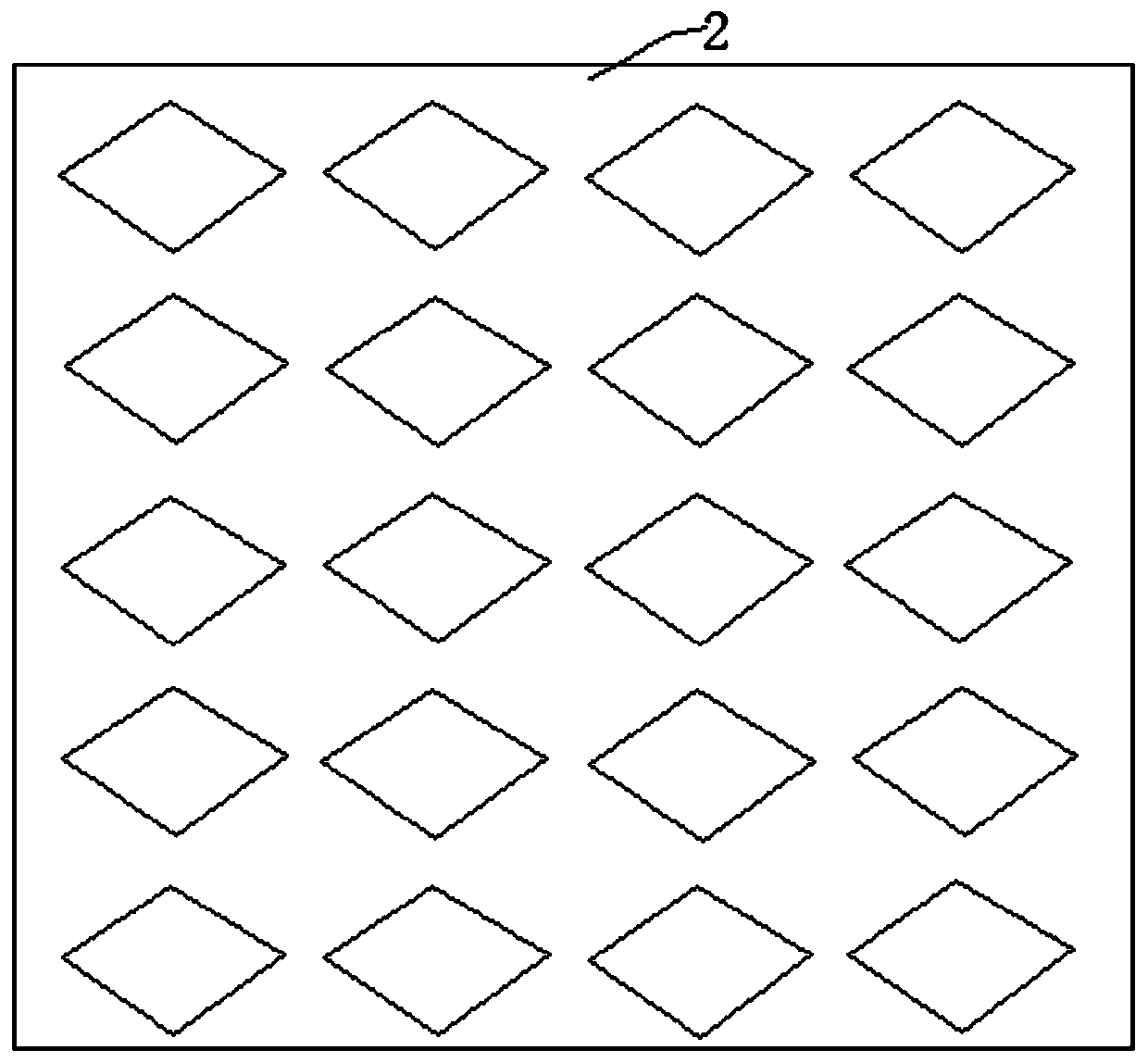

[0047] Wherein, the metal layer 2 may be implemented in the following ways:

[0048] 1. It can be a...

Embodiment 2

[0082] Such as Figure 13 and Figure 14 As shown, this embodiment provides an OLED device, which includes a substrate 6, a functional layer 7 sequentially arranged on the substrate 6, and a thin film encapsulation junction for encapsulating the functional layer 7 on the substrate 6, wherein the thin film encapsulation The structure adopts the implementation method in Example 1; the functional layer 7 includes a first electrode 8 , an organic functional layer 9 and a second electrode 10 .

[0083] in:

[0084] The substrate 6 can be a rigid substrate or a flexible substrate; the material of the first electrode 8 can be ITO (indium tin oxide), AZO (aluminum-doped zinc oxide), preferably ITO; the organic functional layer 9 includes a hole transport layer, a luminescent Layer and electron transport layer, provide light source for the whole device, prepared by evaporation, spin coating, inkjet printing, etc.; the second electrode 10 is used as a cathode, and the electrode materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com