Composite thin film and manufacturing method, organic light emitting diode and packaging method

A technology of light-emitting diodes and composite thin films, which is applied in the direction of organic semiconductor devices, semiconductor/solid-state device manufacturing, coating, etc., can solve the problems that organic light-emitting diodes and thin films cannot be prepared separately, achieve good results, firm packaging, and simplify the production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0061] comprising at least three PDDA layers and at least three graphene oxide layers;

[0062] PDDA layers and graphene oxide layers are alternately deposited, and the last deposited layer is a graphene oxide layer.

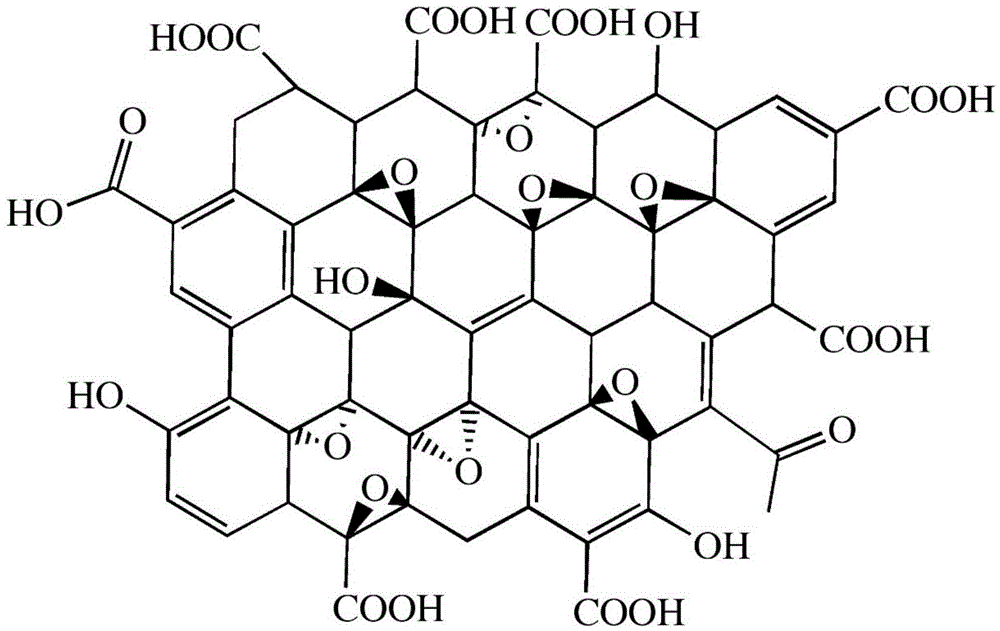

[0063] Because graphene has good water and oxygen barrier properties, graphene is traditionally used as a packaging material, but the preparation, processing, and transfer processes of graphene are complicated, and it is not suitable for large-scale use, let alone industrial production. In this application, graphene oxide is used as the packaging material. The graphene oxide layer is easy to prepare and process, and is suitable for industrial production, but according to figure 1 It can be seen from the schematic diagram of the micro-fragment structure of graphene oxide that although the main body of graphene oxide still maintains the ring structure of graphene, it can penetrate water molecules and Oxygen molecules, resulting in reduced water and oxygen resista...

Embodiment 1

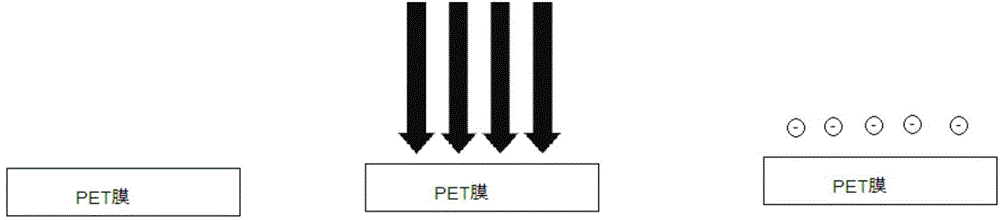

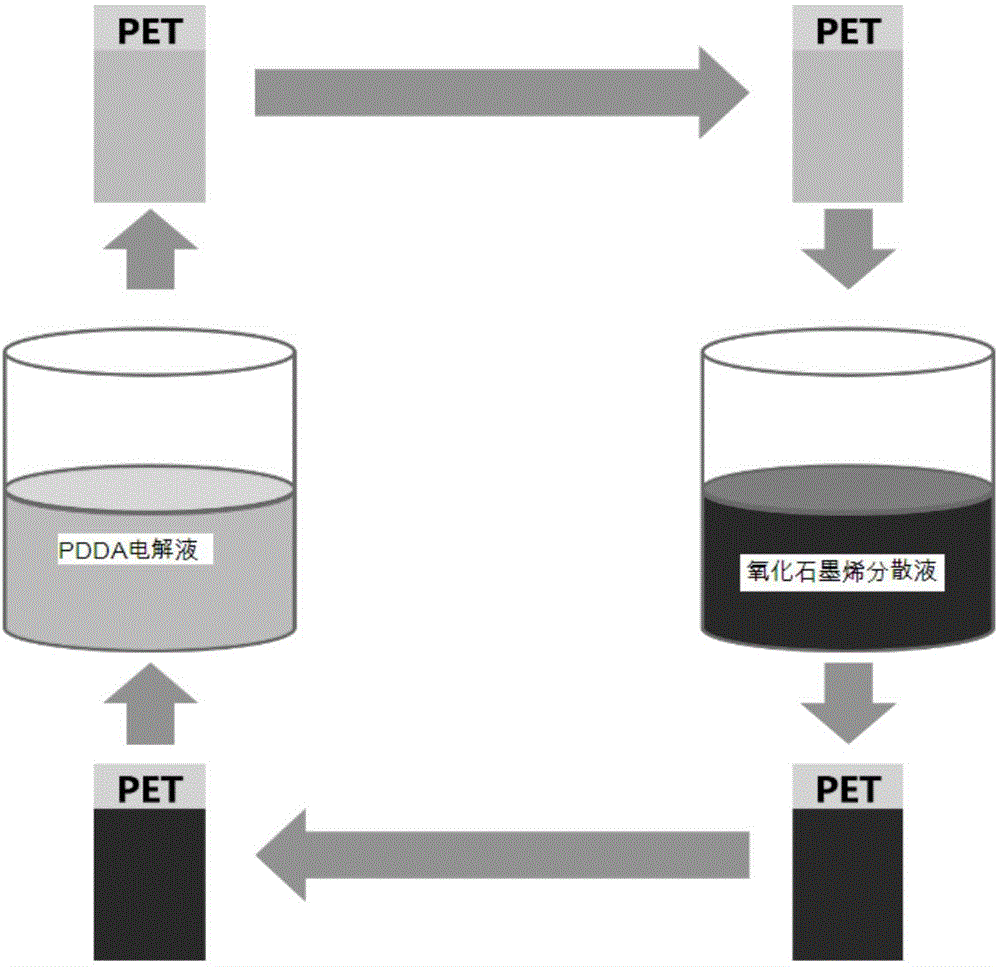

[0095]According to the preparation method of the composite film of the present invention, the PET film is selected as the base film, and the base film pretreatment step is first carried out: the first side of the base film is irradiated with oxygen plasma, so that the first side of the base film produces negative oxygen ions; Deposition step: deposit the pretreated PET film in PDDA electrolyte solution, deposit the PET film deposited with PDDA layer in the dispersion of graphene oxide, and repeat the above deposition operation until three layers are deposited on the base film. Layer PDDA layer and three layers of graphene oxide layers, and the last deposited layer is a graphene oxide layer; finally carry out the self-assembly step: the PET film deposited with the graphene oxide layer is placed in the solution of the compound shown in formula I to soak, so that The compound shown in formula I is self-assembled on the graphene oxide layer. The concentration of the methanol soluti...

Embodiment 2

[0097] According to the preparation method of the composite film of the present invention, the base film is a PET film, and the base film pretreatment step is first carried out: the first side of the PET film is irradiated with oxygen plasma, so that the first side of the base film produces negative oxygen ions; then electrostatic deposition is carried out Steps: place the pretreated PET film in PDDA electrolyte solution for deposition, place the PET film deposited with PDDA layer in the dispersion of graphene oxide for deposition, and cycle through the above deposition operations until the base film is deposited with Four layers of PDDA layers and four layers of graphene oxide layers, and the last deposited layer is a graphene oxide layer; the last self-assembly step: the PET film deposited with the graphene oxide layer is placed in the solution of the compound shown in formula I to soak, The compound shown in formula I is self-assembled on the graphene oxide layer, the concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com