Preparation method of fluorine-containing polyvinylidene chloride emulsion for coating

A polyvinylidene chloride and vinylidene chloride technology, applied in the direction of coating, can solve the problems of poor chemical stability and weather resistance, difficult to ensure binding, poor chemical stability, etc., and achieve good emulsion stability and reaction conditions. Easy to control, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

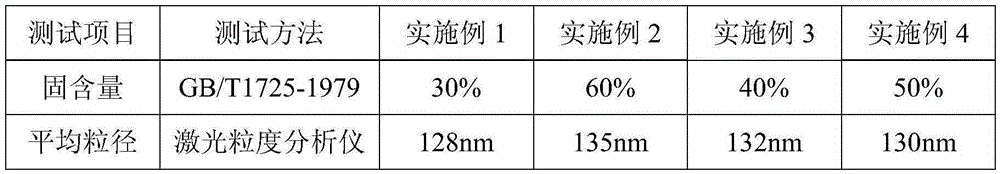

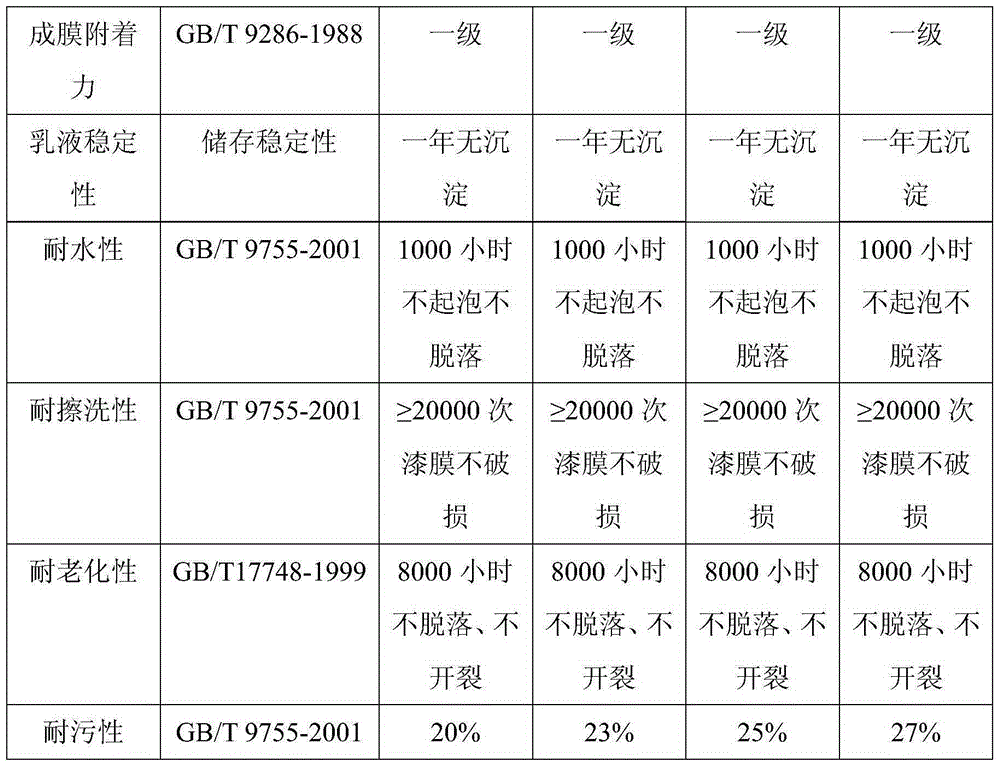

Examples

Embodiment 1

[0027] A preparation method of fluorine-containing polyvinylidene chloride emulsion for coating, comprising the following steps:

[0028] (1) Prepare the raw materials for the reaction

[0029] The raw material formula is as follows:

[0030] Deionized water: 73kg

[0031] Emulsifier: sodium lauryl sulfate 2.5kg, nonylphenol polyoxyethylene ether (NP-10): 2.5kg

[0032] pH regulator: sodium bicarbonate 0.5kg,

[0033] Acrylic monomer: methyl methacrylate 2.68kg, methyl acrylate 0.6kg, methacrylic acid 0.12kg

[0034] Vinylidene chloride monomer: 20kg

[0035] Initiator: tert-butyl hydroperoxide 0.075kg, sodium formaldehyde sulfoxylate 0.075kg

[0036] Perfluoroalkyl ethyl acrylate monomer: perfluorohexyl ethyl acrylate 7kg

[0037] (2) Preparation of seed emulsion

[0038] Add 70kg of deionized water, emulsifier (1kg of sodium lauryl sulfate, 1kg of nonylphenol polyoxyethylene ether), and 0.5kg of pH regulator sodium bicarbonate into a 150L reactor, then stir at 10°C an...

Embodiment 2

[0044] A preparation method of fluorine-containing polyvinylidene chloride emulsion for coating, comprising the following steps:

[0045] (1) Prepare the raw materials for the reaction

[0046] The raw material formula is as follows:

[0047] Deionized water 43kg

[0048] Emulsifier: dodecylbenzenesulfonic acid 8kg, octylphenol polyoxyethylene ether (OP-10): 6kg, sodium dodecylbenzenesulfonate 1kg,

[0049] pH adjuster: ammonium bicarbonate 3kg

[0050] Acrylic monomer: methyl acrylate 6.3kg, butyl acrylate 1.35kg, acrylic acid 0.35kg

[0051] Vinylidene chloride monomer: 32kg,

[0052] Initiator: ammonium persulfate 0.3kg

[0053] Perfluoroalkyl ethyl acrylate monomer: perfluorooctyl ethyl acrylate 20kg

[0054] (2) Preparation of seed emulsion

[0055] Add 40kg of deionized water, emulsifier (4kg of dodecylbenzenesulfonic acid, 2kg of octylphenol polyoxyethylene ether), and 3kg of pH regulator ammonium bicarbonate into the reaction kettle, and then stir at 25°C and 20...

Embodiment 3

[0061] A preparation method of fluorine-containing polyvinylidene chloride emulsion for coating, comprising the following steps:

[0062] (1) Prepare the raw materials for the reaction

[0063] The raw material formula is as follows:

[0064] Deionized water 63kg,

[0065] Emulsifier: sodium dodecyl diphenyl ether sulfonate (2A1): 2kg, fatty alcohol polyoxyethylene ether (TMN-10): 1kg, potassium perfluorobutylsulfonate 0.75kg, octylphenol polyoxyethylene ether (OP-10): 0.75kg, sodium perfluorohexyl ethyl sulfonate 1.5kg

[0066] pH adjuster: sodium dihydrogen phosphate 1kg

[0067] Acrylic monomer: methyl methacrylate 4.25kg, ethyl acrylate 0.5kg, acrylic acid 0.25kg

[0068] Vinylidene chloride monomer: 25kg,

[0069] Initiator: potassium persulfate 0.1kg, carving white powder 0.075kg

[0070] Perfluoroalkyl ethyl acrylate monomer: perfluorodecyl ethyl acrylate 5kg, perfluorohexyl ethyl acrylate 8kg

[0071] (2) Preparation of seed emulsion

[0072] Add 60kg of deioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com