White light OLED device

A technology for light-emitting devices and blue light-emitting layers, which is applied in the manufacture of electric solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of weak light output, poor light color stability, thick device thickness, etc., to improve light color stability. The effect of improving the resistance to water and oxygen, and improving the light emitting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

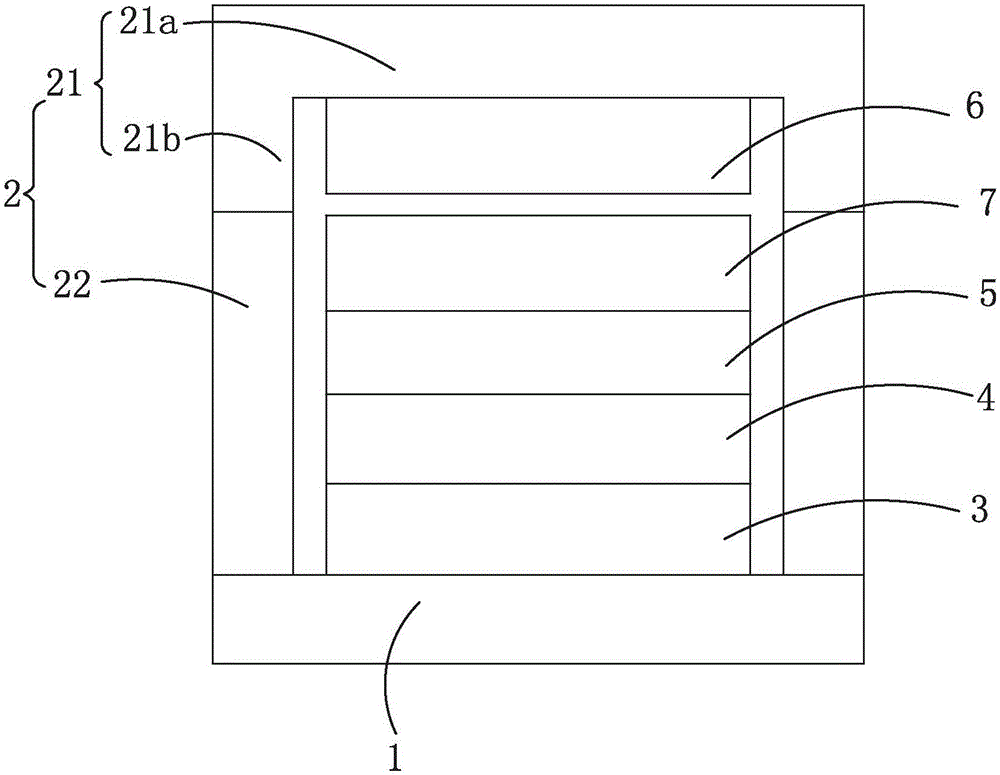

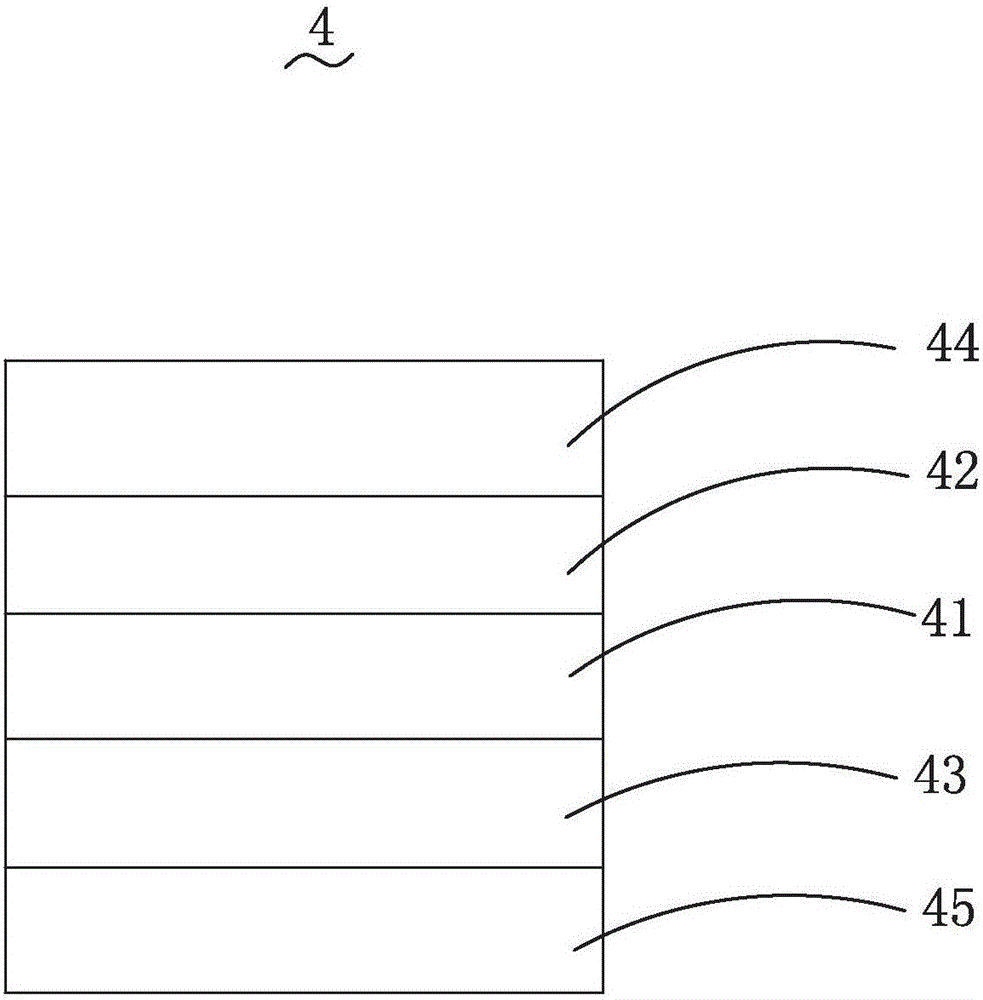

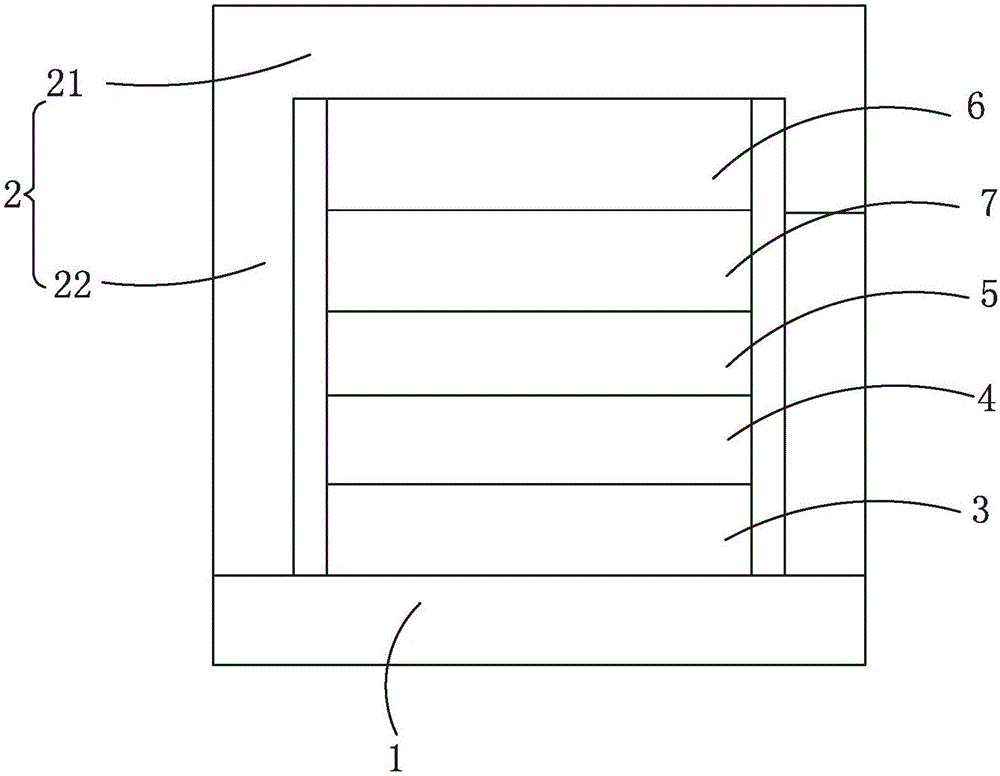

[0032] Such as figure 1 As shown, the present application provides a white light OLED light-emitting device, including a substrate 1, an encapsulation layer 2 that is sealed and connected with the substrate 1 to form a sealed space, and an encapsulation layer 2 that is housed in the encapsulation space and sequentially formed on the substrate 1. An anode conductive layer 3 , a blue light emitting layer 4 and a cathode conductive layer 5 . Wherein, the substrate 1 is used as a carrier for each conductive layer and light emitting layer, and each conductive layer and light emitting layer can be deposited on the substrate 1 by vacuum thermal evaporation or spin coating process. The material of the substrate 1 can be selected from glass, ceramics and the like.

[0033] In this application, the white OLED light emitting device f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com