Waste lubricating oil pretreatment method

A waste lubricating oil and pretreatment technology, which is applied in the direction of lubricating compositions, etc., can solve the problems of not taking into account the metal removal of additives and affecting the effect of pretreatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

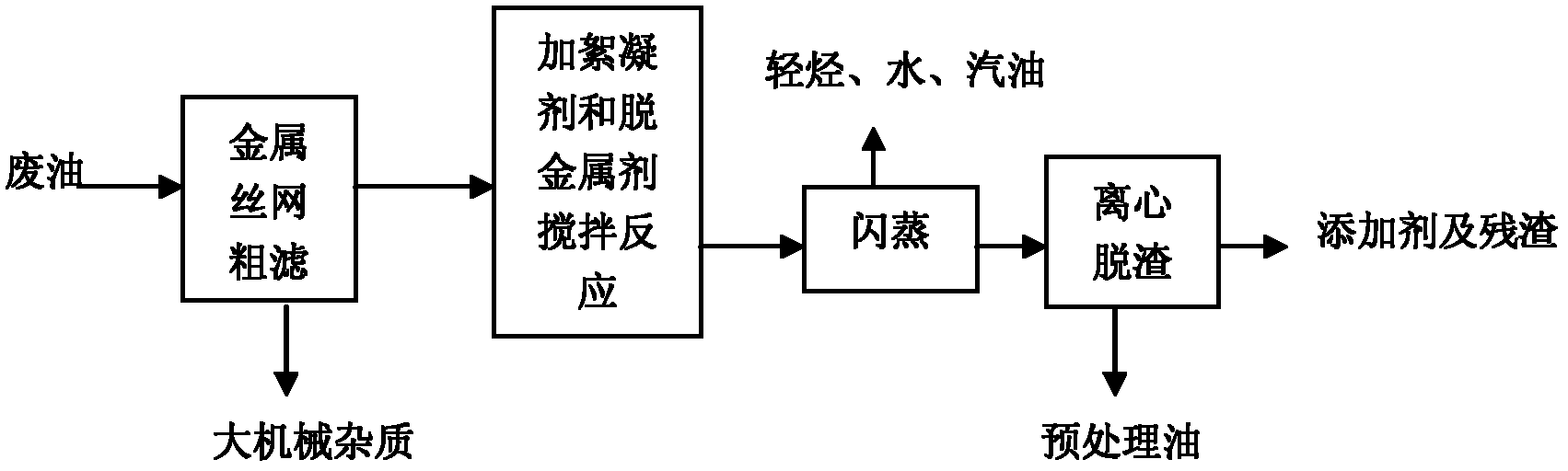

[0022] 1) filter the waste internal combustion engine oil I with a wire mesh (150 mesh) to remove large mechanical impurities;

[0023] 2) Take 400 g of waste lubricating oil I in step 1), add 8 g of pretreatment agent to it, and keep stirring and reacting at 30° C. for 20 minutes; the pretreatment agent is a commercially available organic flocculant A and a commercially available The mixture of metal agent B, the mass ratio of A and B mixed is 0.9:1 (m / m);

[0024] 3) Put the reacted mixture in a three-necked flask for flash evaporation to remove water and light hydrocarbons (nitrogen gas protection, control the temperature of the kettle ≯ 200°C);

[0025] 4) Centrifugal deslagging of materials from which light hydrocarbons, moisture, and gasoline have been removed;

[0026] 5) After the centrifugation, pour out the supernatant as the pretreated oil, and analyze the relevant properties of the pretreated oil.

[0027] At the same time, only the waste internal combustion engi...

Embodiment 2

[0032] 1) Use wire mesh (150 mesh) to filter waste internal combustion engine oil II to remove large mechanical impurities;

[0033] 2) Take 400g of the waste lubricating oil II in step 1), add 8g of pretreatment agent to it, and keep stirring and reacting at 30°C for 20 minutes; the pretreatment agent is a commercially available organic flocculant A and a commercially available The mixture of metal agent B, the mass ratio of A and B mixed is 1.1:1 (m / m);

[0034] 3) Place the reacted mixture in a three-necked flask for flash evaporation to remove water and light hydrocarbons (nitrogen gas protection, control the temperature of the kettle ≯ 200°C);

[0035] 4) Centrifugal deslagging of materials from which light hydrocarbons, moisture, and gasoline have been removed;

[0036] 5) After the centrifugation is completed, the supernatant is poured out as the pretreated oil, and the relevant properties of the pretreated oil are analyzed.

[0037] At the same time, only the waste i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com