Capacitive pressure sensor and manufacturing method thereof

A technology of a pressure sensor and a manufacturing method, which is applied in fluid pressure measurement, instrumentation, and force measurement using capacitance changes, and can solve problems such as large parasitic capacitance, reduced device performance, and expensive manufacturing costs, achieving low cost and solving release time Long and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manner of the present invention is described in more detail below with reference to the accompanying drawings of the present invention.

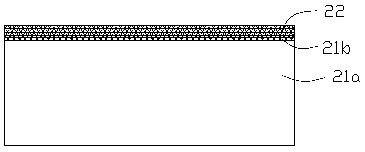

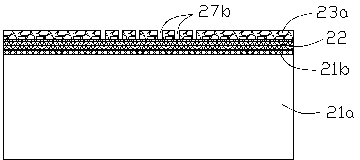

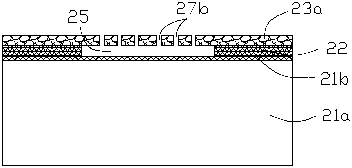

[0034] The present invention discloses a capacitive pressure sensor 20 and its manufacturing method, please refer to Figures 1A to 1G Shown, wherein the manufacturing method of capacitive pressure sensor of the present invention comprises the steps:

[0035] a) Please refer to Figure 1A As shown, heavy doping is first performed on the substrate 21a to obtain a highly conductive heavily doped layer as the lower plate 21b of the capacitive pressure sensor 100 of the present invention, and then silicon oxide is deposited on the lower plate 21b to form the sacrificial layer 22 . Deposition methods include, but are not limited to, low pressure chemical vapor deposition (LPCVD) and plasma enhanced vapor deposition (PECVD). The substrate 21a is a silicon substrate.

[0036] b) Please refer to Figure 1B As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com