Automatic granulating machine

A granulator and automatic technology, applied in the field of agricultural equipment, can solve the problems of affecting granulation, slow granulation position, and affecting granulation effect, so as to achieve the effect of less manual operation, high granulation efficiency and good fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

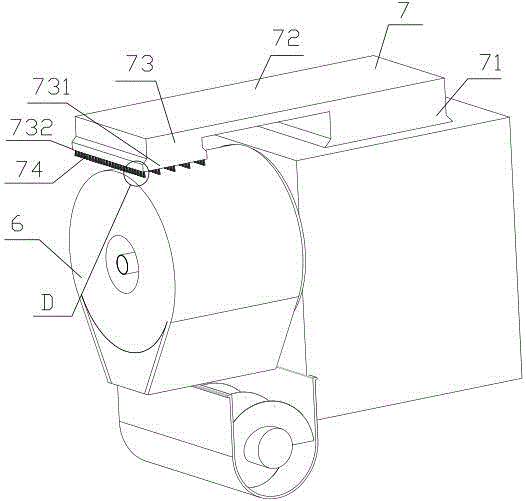

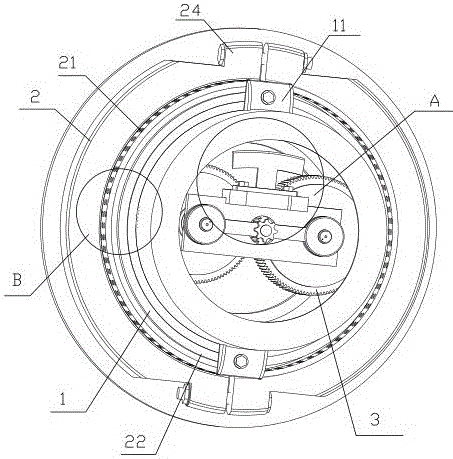

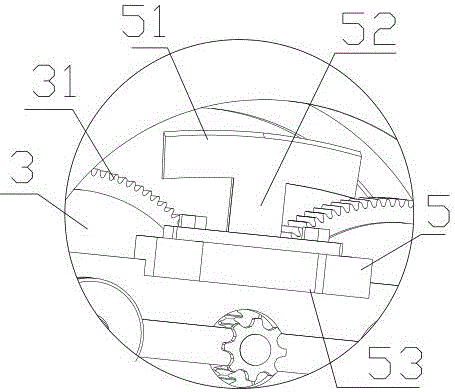

[0045] Example 1, such as figure 1 — Figure 8Shown: an automatic granulator, including a cover body and an inner cavity set in the cover body, and also includes a pressure wheel 3 set in the inner cavity, there are at least two pressure wheels 3, and the pressure wheels 32 include interlocking Pressure teeth 31; also includes a rotary scraper 5 that guides the material to the pressure rollers 3 in the inner cavity and a spacing adjustment device 4 that connects at least two pressure rollers 3 and is used to adjust the gap between the pressure rollers 3, the spacing adjustment The adjustment device 4 includes a telescopic adjustment rod 41, a marker 42 for marking the extension length of the adjustment rod 41 and a detection member 43 for detecting the marker 42, and the two ends of the adjustment rod 41 are respectively connected to the pressure rollers 3; the inner cover body 1 is provided with a fixed ear 11 for connecting with the outer cover body 2. The outer cover body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com