Bisphenol A production granulating system

A granulation and granulation tower technology, applied in the field of bisphenol A production granulation system, can solve the problem of not ensuring the uniform distribution of the rising nitrogen flow, and achieve the effects of reasonable structure, uniform particle size, and guaranteed heat exchange effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

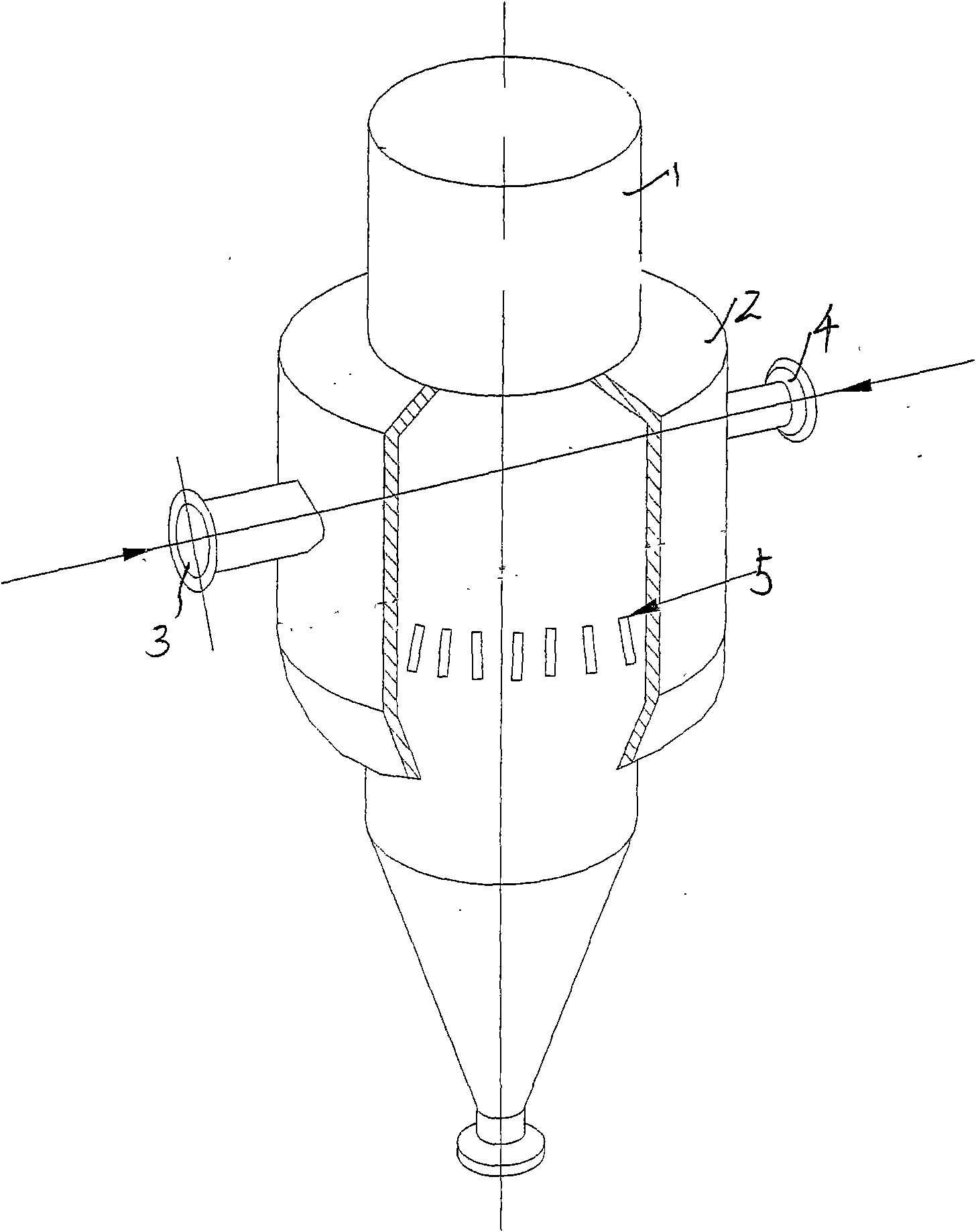

[0015] A production and granulation system for bisphenol A, comprising a granulation tower, the granulation tower has a granulation tower body 1, a casing 2 is arranged at the lower part of the prilling tower body, the upper and lower ends of the casing are sealed and joined with the prilling tower body, There is a nitrogen chamber between the tower bodies, cooling nitrogen inlets 3 and 4 are arranged on the jacket, and a plurality of nitrogen gas inlet holes 5 are arranged at the same height of the prilling tower body inside the jacket.

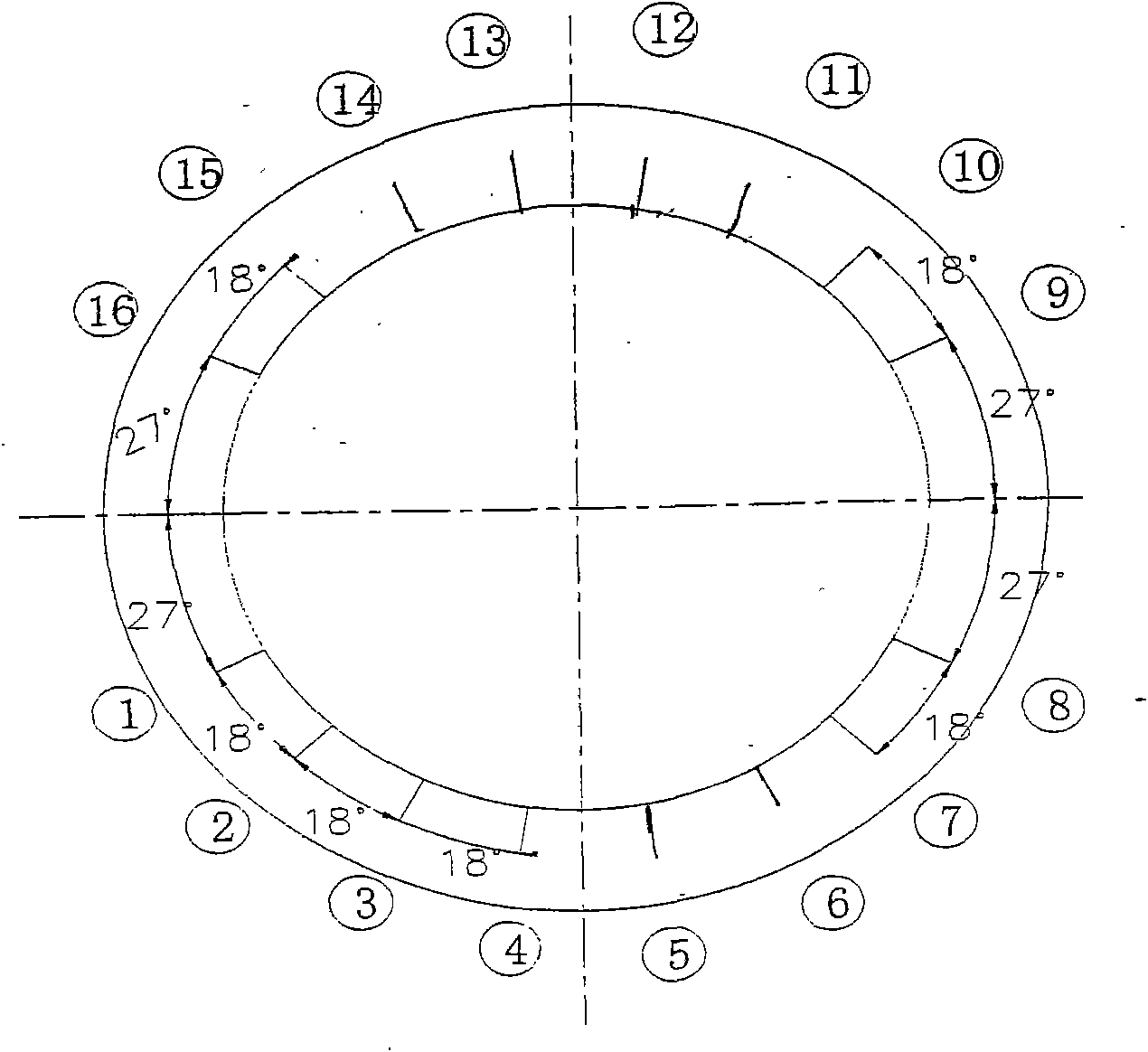

[0016] There are 16 nitrogen air intake holes, and the air intake holes are rectangular.

[0017] The cross-section of the prilling tower body is circular, and the ①, ⑧, ⑨, ⑨ Air intake holes, the ② to ⑦ air intake holes are evenly arranged between the ① air intake hole and the ⑧ air intake hole, and the ⑨ air intake hole and the ⑧ air intake hole The ⑩~th air intake. The size of the air inlet is 1240×500mm, and the long side is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com