Granulator device for producing veterinary drugs

A granulator and animal production technology, applied in the direction of granulating raw materials, chemical instruments and methods, chemical/physical processes, etc., can solve unreasonable distribution of powder materials, uneven transportation of raw materials, and easy jamming of granulation mechanisms housing and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

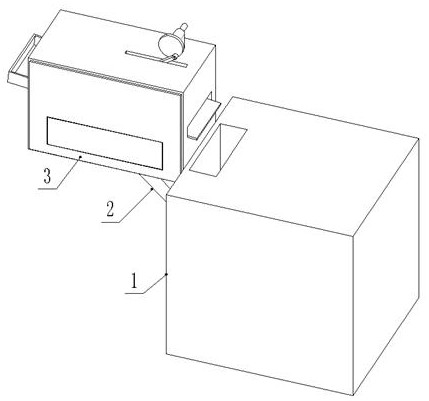

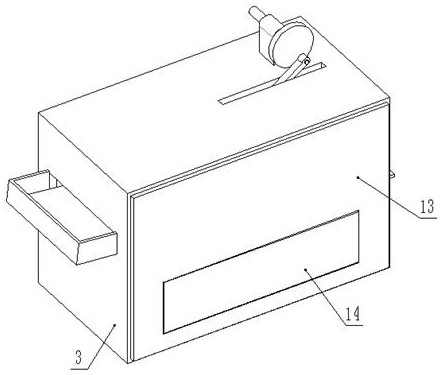

[0019] Example 1: Please refer to figure 1 , a granulator device for producing veterinary medicine, comprising a granulating mechanism 1 and a bracket 2, the granulating mechanism 1 is supported and fixed with a feeding box 3 through the bracket 2, the output end of the feeding box 3 is connected to the feeding end of the granulating mechanism 1 corresponding to the location.

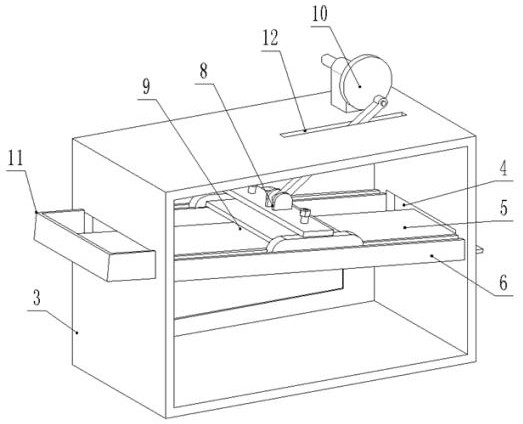

[0020] see image 3 , the two sides of the feeding box body 3 are provided with a mounting opening 4 with a height difference, and an inclined material guide plate 5 is arranged in the installation opening 4, and baffle plates 6 are fixedly connected to both sides of the material guide plate 5, and the baffle plate 6 is connected to the guide plate. The inclination angles of the feed plates 5 are equal, the baffle plate 6 is provided with a slot 7 along its length, and the baffle plates 6 on both sides are slidably connected with a gap adjustment assembly 8 through the slot 7, and the gap adjustment as...

Embodiment 2

[0025] Example 2: Please refer to figure 1 , a granulator device for producing veterinary medicine, comprising a granulating mechanism 1 and a bracket 2, the granulating mechanism 1 is supported and fixed with a feeding box 3 through the bracket 2, the output end of the feeding box 3 is connected to the feeding end of the granulating mechanism 1 corresponding to the location.

[0026] see image 3 , the two sides of the feeding box body 3 are provided with a mounting opening 4 with a height difference, and an inclined material guide plate 5 is arranged in the installation opening 4, and baffle plates 6 are fixedly connected to both sides of the material guide plate 5, and the baffle plate 6 is connected to the guide plate. The inclination angles of the feed plates 5 are equal, the baffle plate 6 is provided with a slot 7 along its length, and the baffle plates 6 on both sides are slidably connected with a gap adjustment assembly 8 through the slot 7, and the gap adjustment as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com