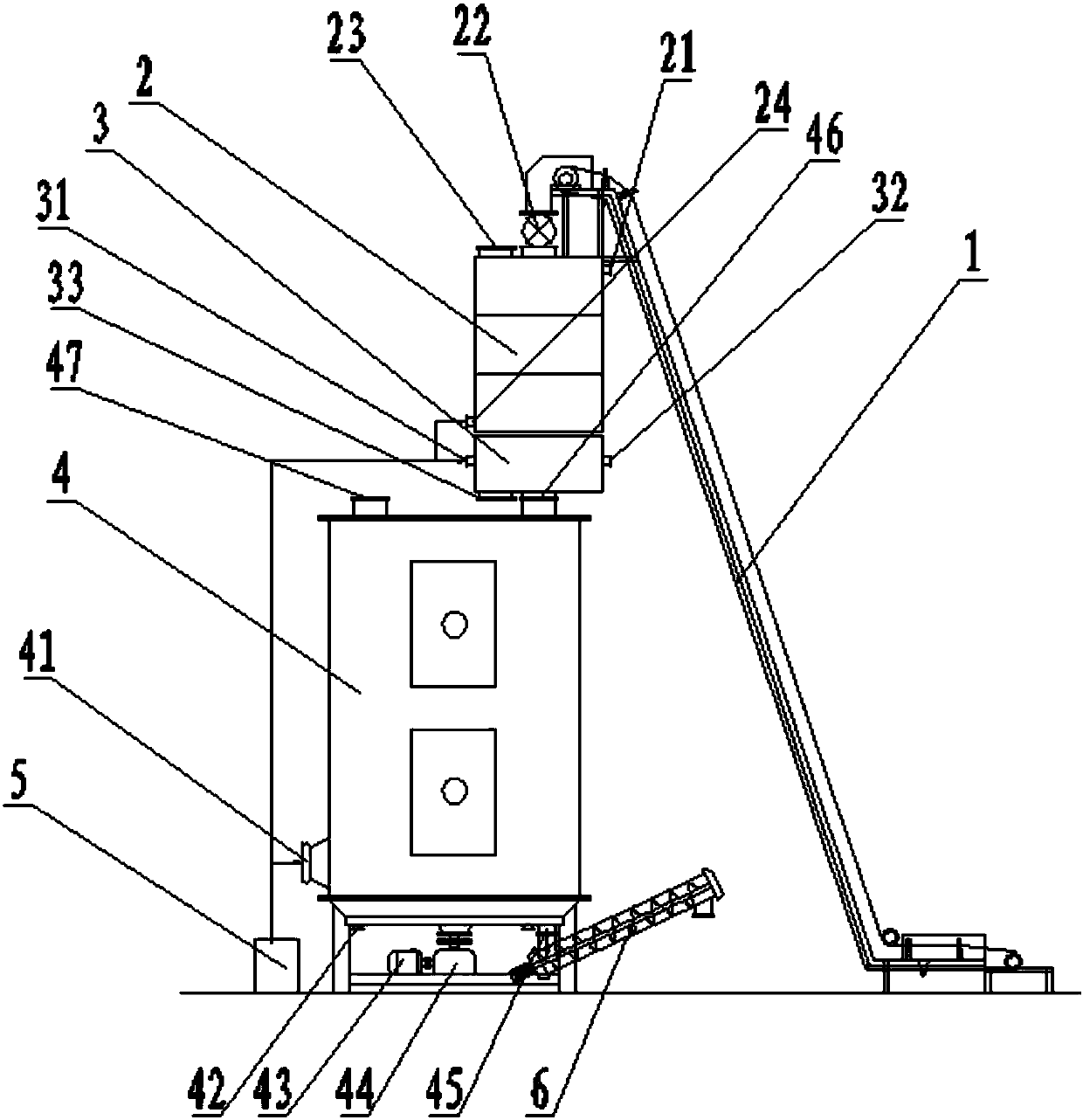

Method and device for carrying out drying treatment on sludge

A sludge drying and treatment device technology, which is applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of low drying efficiency, unfavorable green treatment, and unfavorable energy conservation issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

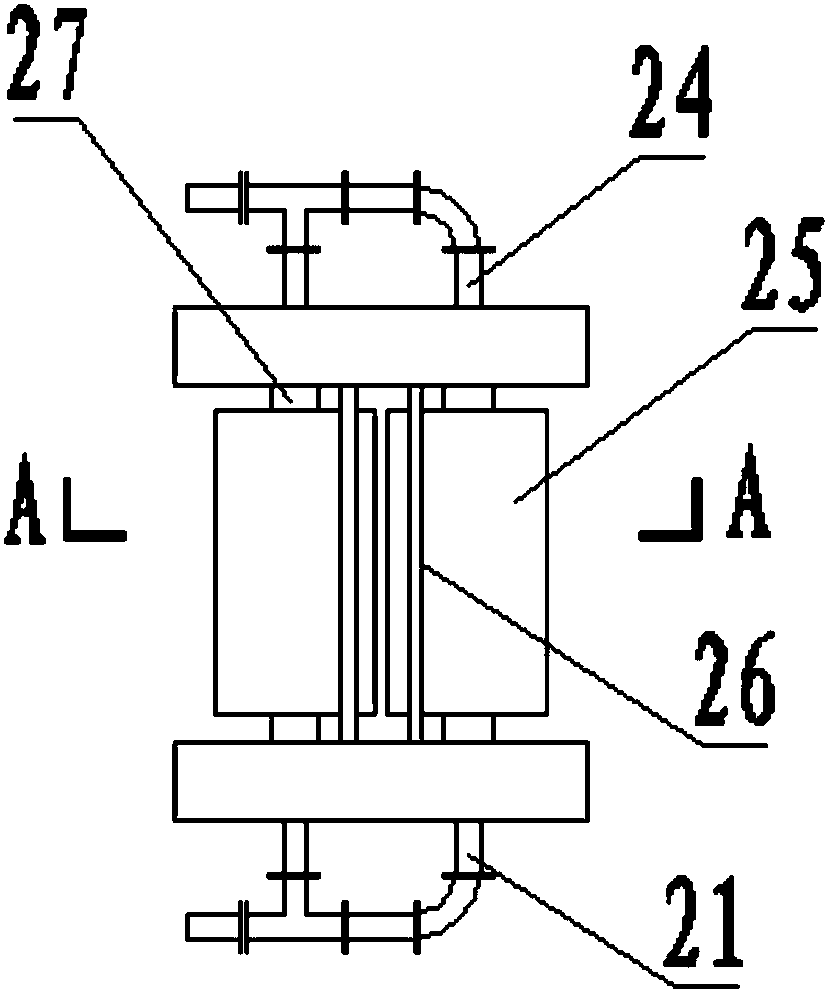

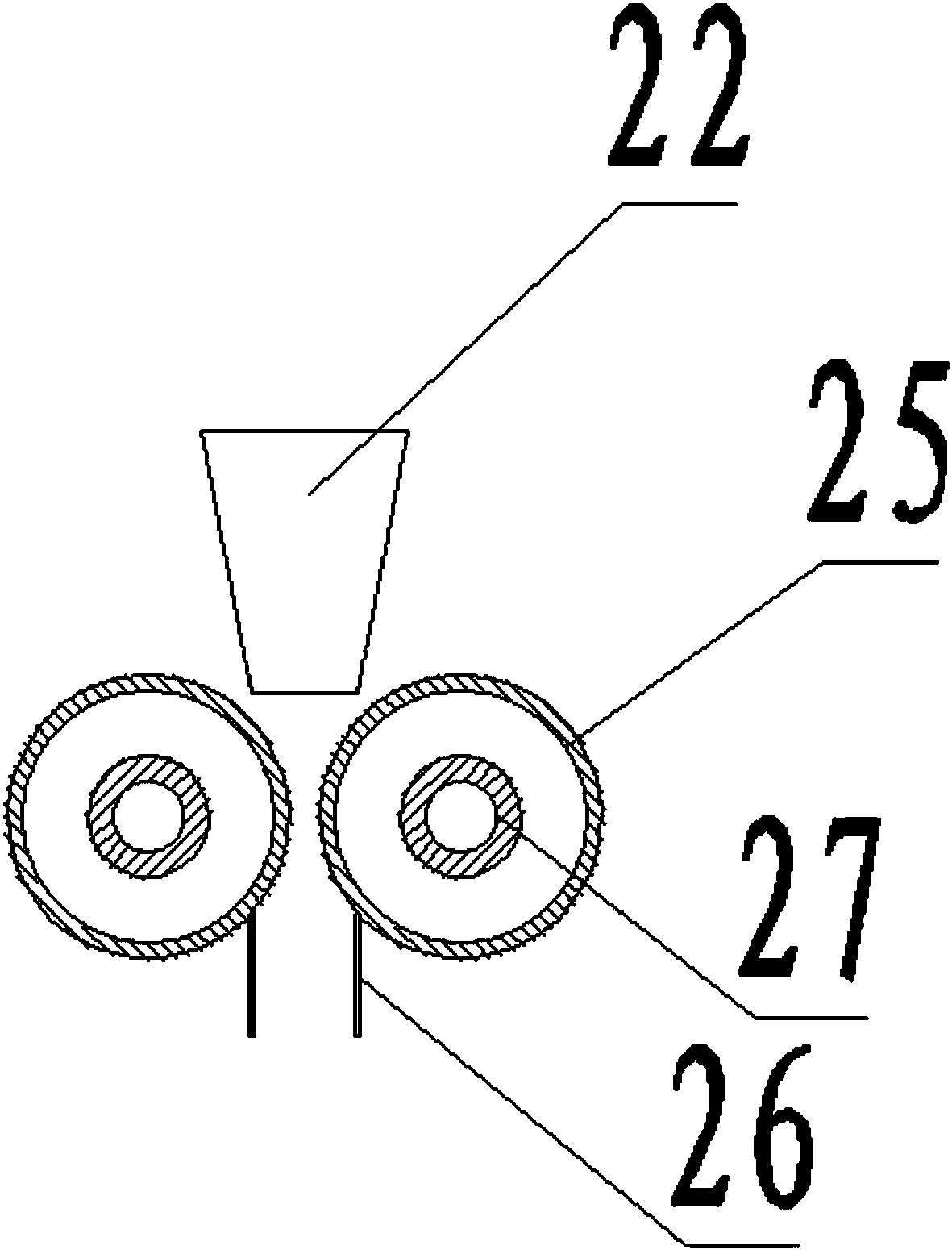

[0044] The main structure of this embodiment is basically the same as that of the first embodiment. The difference is that the number of stages of the roller press 2 is a natural number not greater than 10, preferably 3 stages, and the pitch of the counter-rotating drum 25 of the roller press 2 is sequentially Decrease; the number of stages of the toothed knife granulator 3 is a natural number not greater than 10, preferably 2, and the spacing of the counter-rotating toothed knives 34 of the toothed knife granulator 3 is sequentially reduced. The purpose of this design is to use energy more efficiently while ensuring the molding rate and dryness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com