Stepped mold straw granulation device

A ladder-shaped, straw-shaped technology, which is applied in the field of ladder-shaped straw granulation devices, can solve the problems of large energy consumption and increased straw granulation costs, and achieve high production efficiency, ensure granulation effect, and reduce sliding friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

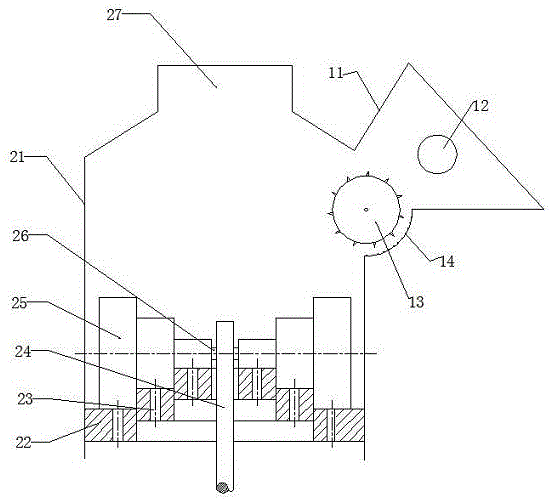

[0019] like figure 1 A stepped mold straw granulation device shown includes a feeding chamber 21, a forming die 22 arranged at the bottom of the feeding chamber 21, a rotating shaft 24 driven by a power mechanism that vertically penetrates the forming die 22, and is symmetrical to the rotating shaft 24. The two transmission rods 26 extending outward, and the pressure rollers 25 connected to the transmission rods 26 are coaxially rotated respectively. The upper surface is in the shape of three layers of steps descending from the center of the circle to the edge, and each layer is respectively provided with a forming hole 23. The pressure roller 25 is in the shape of a boss whose diameter increases along the extension direction of the transmission rod 26. The pressure roller 25 and the forming die 22 to match the shape of the upper surface.

[0020] It also includes a rubbing and breaking machine whose discharge port communicates with the charging chamber 21 feed ports. The rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com